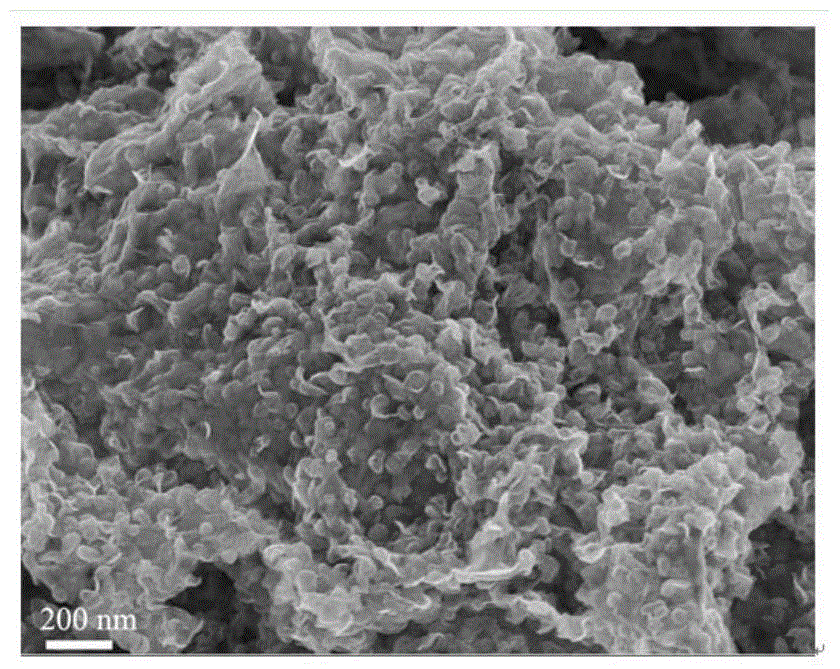

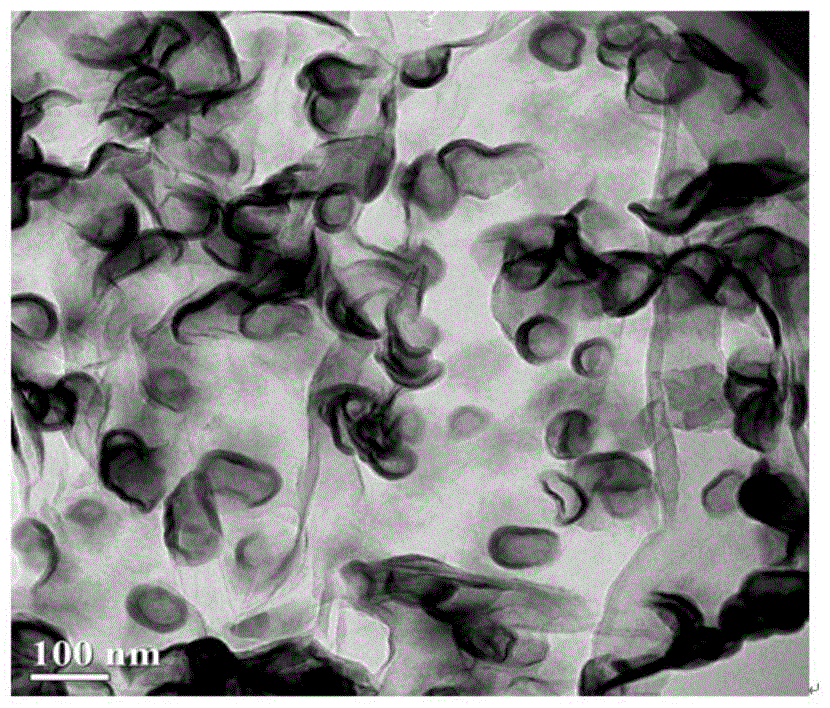

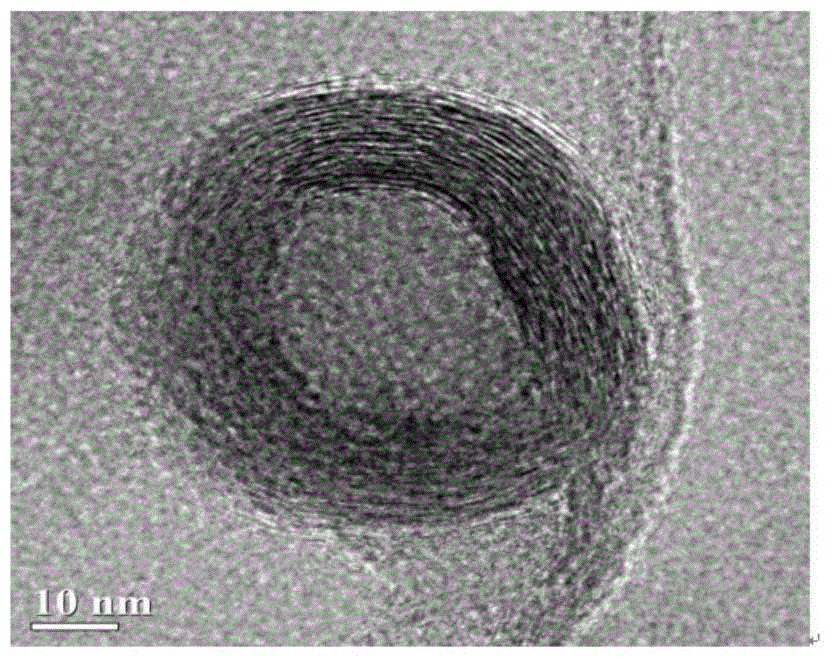

High nitrogen-doped graphene and fullerene-like molybdenum selenide hollow sphere nanocomposite material and preparation method thereof

A nanocomposite material, nitrogen-doped graphene technology, applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve the problems of few, difficult, and few studies on heterogeneous atom doping, and achieve experimental instruments Inexpensive, reduced oxygen-containing groups, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1) Preparation of low-nitrogen-doped graphene: Disperse 500 mg of graphene oxide (produced by the Hummers method) into 100 mL of aqueous solution, stir and sonicate to disperse evenly; then add 5 mL of NH to the dispersion 3 ·H 2 O (20%), stirring and heating to 90 ° C, through a chemical reaction for 2 hours, to obtain rough low-nitrogen graphene; finally, obtain high-quality low-nitrogen graphene through dialysis.

[0032] 2) Preparation of chemical reaction solution: 0.2mmol of ammonium molybdate tetrahydrate, i.e. (NH 4 ) 6 Mo 7 o 24 4H 2 O and 3 mmol of Na 2 SeO 3 Dissolve in 15mLH 2 In the mixed solution that O and 15mL ethylene glycol form, stir 15 minutes;

[0033] Add 5 mL of diethylenetriamine (DETA) stabilizer to the above solution, stir for 15 minutes; get 5 low-nitrogen-doped graphene and add to the above solution, stir and sonicate for 30 minutes;

[0034] 3) Preparation of high-nitrogen-doped graphene and fullerene-like molybdenum selenide hollow...

Embodiment 2

[0036] 1) Preparation of low-nitrogen-doped graphene: Disperse 500 mg of graphene oxide (produced by the Hummers method) into 100 mL of aqueous solution, stir and sonicate to disperse evenly; then add 10 mL of NH to the dispersion 3 ·H 2 O (20%), stirring and heating to 90 ° C, through a chemical reaction for 10 hours, to obtain rough low-nitrogen graphene; finally, obtain high-quality low-nitrogen graphene through dialysis.

[0037] 2) Preparation of chemical reaction solution: 0.5 mmol of ammonium molybdate tetrahydrate, i.e. (NH 4 ) 6 Mo 7 o 24 4H 2 O and 10 mmol of Na 2 SeO 3 Dissolve in 15mLH 2 In a mixed solution composed of O and 15mL ethylene glycol, stir for 15 minutes;

[0038] Add 15 mL of diethylenetriamine (DETA) stabilizer to the above solution, stir for 15 minutes; take 15 mL of low-nitrogen-doped graphene and add it to the above solution, stir and sonicate for 30 minutes;

[0039] 3) Preparation of high-nitrogen-doped graphene and fullerene-like molybd...

Embodiment 3

[0041] 1) Preparation of low-nitrogen-doped graphene: Disperse 500 mg of graphene oxide (produced by the Hummers method) into 100 mL of aqueous solution, stir and sonicate to disperse evenly; then add 15 mL of NH to the dispersion 3 ·H 2 O (20%), stirring and heating to 90 ° C, through a chemical reaction for 10 hours, to obtain rough low-nitrogen graphene; finally, obtain high-quality low-nitrogen graphene through dialysis.

[0042] 2) Preparation of chemical reaction solution: 1.5mmol of ammonium molybdate tetrahydrate, i.e. (NH 4 ) 6 Mo 7 o 24 4H 2 O and 15 mmol of Na 2 SeO 3 Dissolve in 15mLH 2 In a mixed solution composed of O and 15mL ethylene glycol, stir for 15 minutes;

[0043] Add 25mL of diethylenetriamine (DETA) stabilizer to the above solution, stir for 15 minutes; take 20mL of low-nitrogen-doped graphene and add to the above solution, stir and sonicate for 30 minutes;

[0044] 3) Preparation of high-nitrogen-doped graphene and fullerene-like molybdenum s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com