Method for preparing nitrogen-doped graphene and nickel sulfide quantum dot nanometer composite material

A technology of nitrogen-doped graphene and nanocomposite materials, which is applied in the direction of nanotechnology, nanotechnology, metal material coating technology, etc., can solve the problems of failure to achieve material compounding and failure to introduce second phase components, and achieve The effect of cheap experimental equipment, high yield, and controllable reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment includes the following steps:

[0029] 1) adopt Hummers method to prepare graphene oxide powder;

[0030] 2) 3 mmol of nickel nitrate hexahydrate, namely N i (NO 3 ) 2 ·6H 2 O and 3 mmol of L-cysteine were dissolved in 75 mL of H 2 O, then add 5 mL of NH 3 ·H 2 O (20wt%), stirred for 45 minutes, added the graphene oxide powder obtained in 140mg step 1 to the above solution, further stirred and ultrasonicated for 45 minutes;

[0031] 3) Add the product obtained in step 2 to the reaction kettle, heat-treat at 160°C for 12 hours, centrifuge the obtained product, wash it repeatedly with deionized water and absolute ethanol three times, and dry it in a drying oven at 60°C to obtain nitrogen-doped Graphene and nickel sulfide quantum dot nanocomposites.

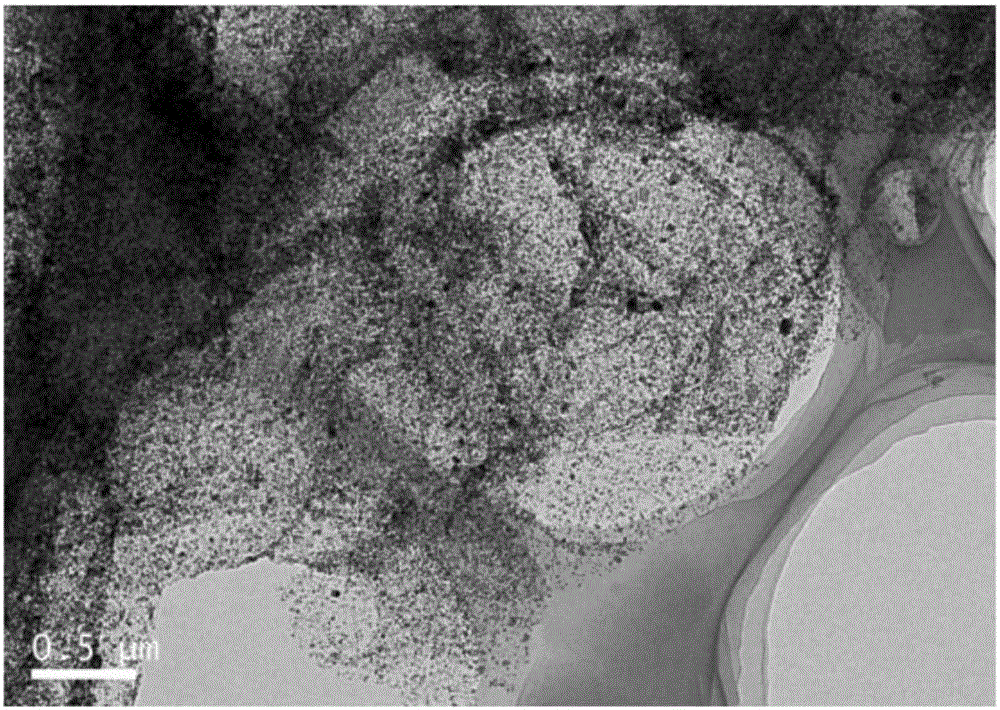

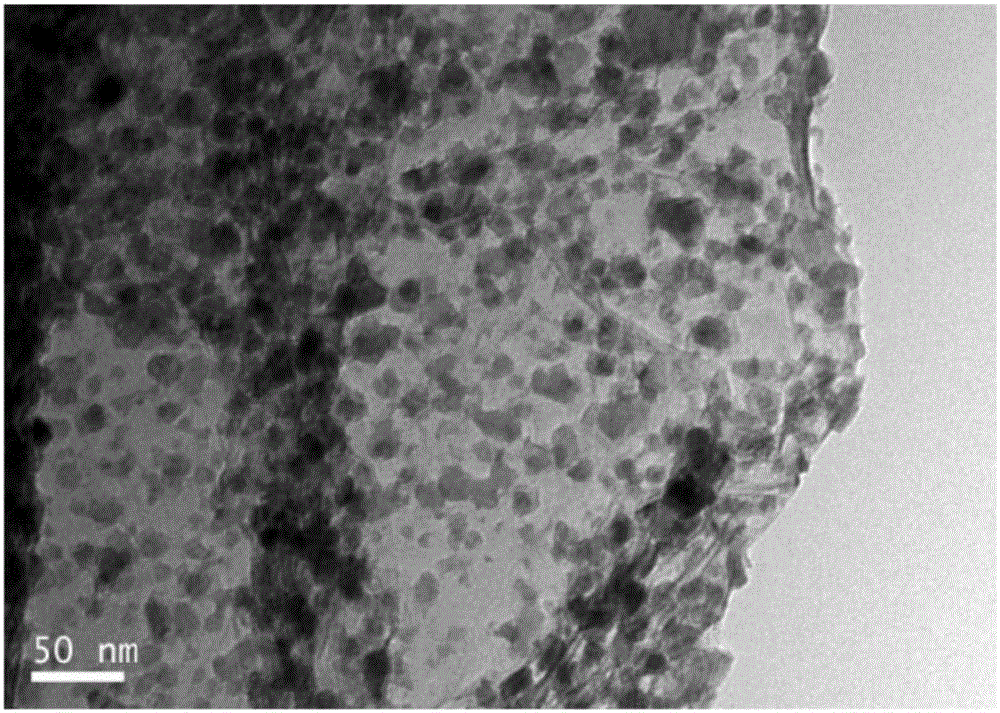

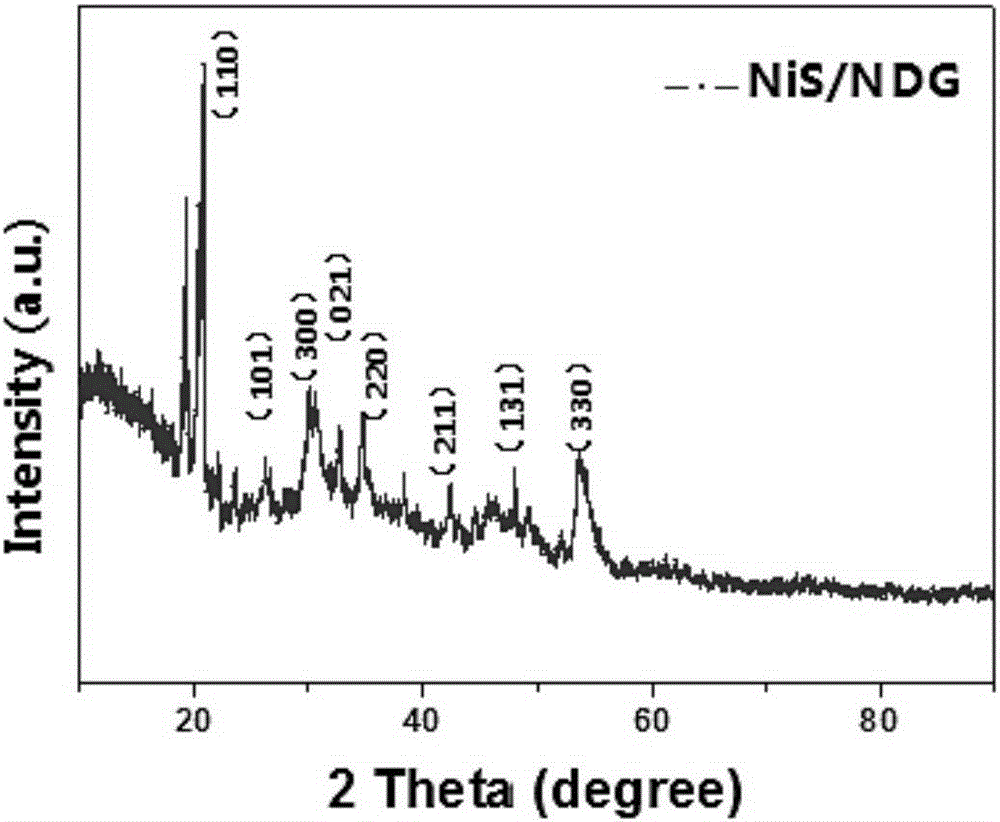

[0032] Such as figure 1 and figure 2 As shown, it is a TEM image of the composite material obtained in this embodiment, and it can be seen that the nickel sulfide quantum dots are very uniformly d...

Embodiment 2

[0035] This embodiment includes the following steps:

[0036] 1) adopt Hummers method to prepare graphene oxide powder;

[0037] 2) 2 mmol of nickel nitrate hexahydrate, namely N i (NO 3 ) 2 ·6H 2 O and 2 mmol of L-cysteine were dissolved in 75 mL of H 2 O, then add 5 mL of NH 3 ·H 2 O (20wt%), stirred for 45 minutes, added 120mg graphene oxide powder in the above solution, stirred and ultrasonicated for 45 minutes;

[0038] 3) Put the product obtained in step 2 into the reaction kettle, heat-treat at 170°C for 12 hours, centrifuge the obtained product, wash it repeatedly with deionized water and absolute ethanol three times, and dry it in a drying oven at 60°C to obtain nitrogen-doped Graphene and nickel sulfide quantum dot nanocomposites.

[0039] Compared with the product prepared in Example 1, the electrical conductivity of the composite material is slightly lower.

Embodiment 3

[0041] This embodiment includes the following steps:

[0042] 1) adopt Hummers method to prepare graphene oxide powder;

[0043] 2) 3 mmol of nickel nitrate hexahydrate, namely N i (NO 3 ) 2 ·6H 2 O and 4 mmol of L-cysteine were dissolved in 75 mL of H 2 O, then add 6 mL of NH 3 ·H 2 O (20wt%), stirred for 45 minutes, added 120mg graphene oxide powder in the above solution, stirred and ultrasonicated for 45 minutes;

[0044]3) The product obtained in step 2 was added to the reaction kettle, heat-treated at 180°C for 8 hours, the obtained product was centrifuged, washed repeatedly with deionized water and absolute ethanol for 3 times, and dried in a drying oven at 60°C to obtain nitrogen-doped Graphene and nickel sulfide quantum dot nanocomposites.

[0045] Compared with the product prepared in Example 1, the nickel sulfide quantum dots are more uniformly distributed on the nitrogen-doped graphene sheet in the product prepared in this example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com