Printing and dyeing wastewater treatment method based on synergistic effect of anion flocculant and cation flocculant

A printing and dyeing wastewater and synergistic technology, which is applied in the direction of flocculation/sedimentation water/sewage treatment, textile industry wastewater treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

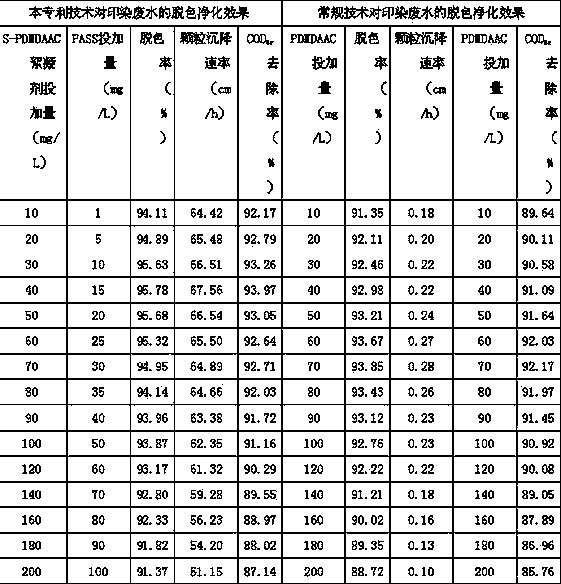

Embodiment 1

[0026] The first step is to use the composite dyeing wastewater provided by textile enterprises [color is reddish brown, COD Cr The value is 950 mg / kg] as the object of decolorization treatment, measure 200 mL and add it to a 250 mL beaker, add hydrophobic dodecyl-containing PDMDAAC modification with an aqueous solution concentration of 10 mg / L~200 mg / L The non-volatile flocculant is S-PDMDAAC [intrinsic viscosity is 3.00 dL / g, and the molar content of hydrophobic structural unit is 2 / 98], after fully stirring for 1 minute, let it stand for 20 minutes to form a large number of tiny flocculation sediment particles;

[0027] The second step is to add high relative molecular weight (about 35 million) sodium polyacrylate (PASS) with a concentration of 1 mg / L~100 mg / L in the aqueous solution to "secondary aggregate" the formed tiny flocculation sediment particles into larger Precipitating particles, shortening their settling time;

[0028] The third step is to measure the absorb...

Embodiment 2

[0033] The first step is to use the composite dyeing wastewater provided by textile enterprises [color is reddish brown, COD Cr The value is 950 mg / kg] as the object of decolorization treatment, measure 200 mL and add it to a 250 mL beaker, add hydrophobic dodecyl-containing PDMDAAC modification with an aqueous solution concentration of 10 mg / L~200 mg / L The permanent flocculant is S-PDMDAAC [intrinsic viscosity is 2.20 dL / g, and the molar content of hydrophobic structural unit is 98 / 2]. After fully stirring for 1 min, let it stand for 20 min to form a large number of tiny flocculation sediment particles;

[0034] The second step is to add high relative molecular weight (about 35 million) sodium polyacrylate (PASS) with a concentration of 1 mg / L~100 mg / L in the aqueous solution to "secondary aggregate" the formed tiny flocculation sediment particles into larger Precipitating particles, shortening their settling time;

[0035] The third step is to measure the absorbance of th...

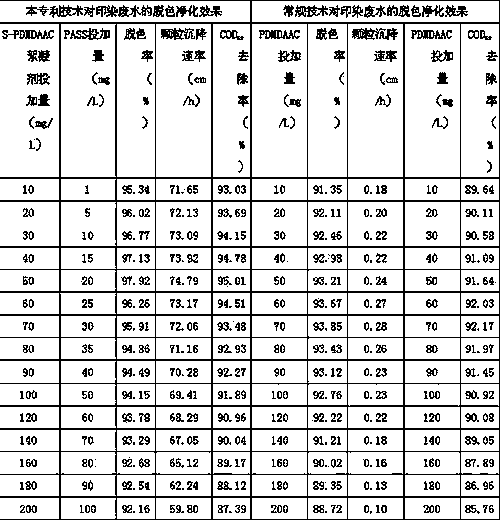

Embodiment 3

[0041] The first step is to use the composite dyeing wastewater provided by textile enterprises [color is reddish brown, COD Cr The value is 950 mg / kg] as the object of decolorization treatment, measure 200 mL and add it to a 250 mL beaker, add hydrophobic tetradecyl-containing PDMDAAC modification with an aqueous solution concentration of 10 mg / L~200 mg / L The non-toxic flocculant is S-PDMDAAC [intrinsic viscosity is 2.51 dL / g, and the molar content of hydrophobic structural unit is 2 / 98], after fully stirring for 1 minute, let it stand for 20 minutes to form a large number of tiny flocculation sediment particles;

[0042] The second step is to add high relative molecular weight (about 35 million) sodium polyacrylate (PASS) with a concentration of 1 mg / L~100 mg / L in the aqueous solution to "secondary aggregate" the formed tiny flocculation sediment particles into larger Precipitating particles, shortening their settling time;

[0043] The third step is to measure the absorb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com