Method for continuously producing solid and liquid organic fertilizer by using livestock and poultry feces

A technology of livestock manure and organic fertilizer, which is applied in the direction of organic fertilizer, excretion fertilizer, fertilizer mixture, etc., to achieve the effect of reducing production cost, realizing resource treatment and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

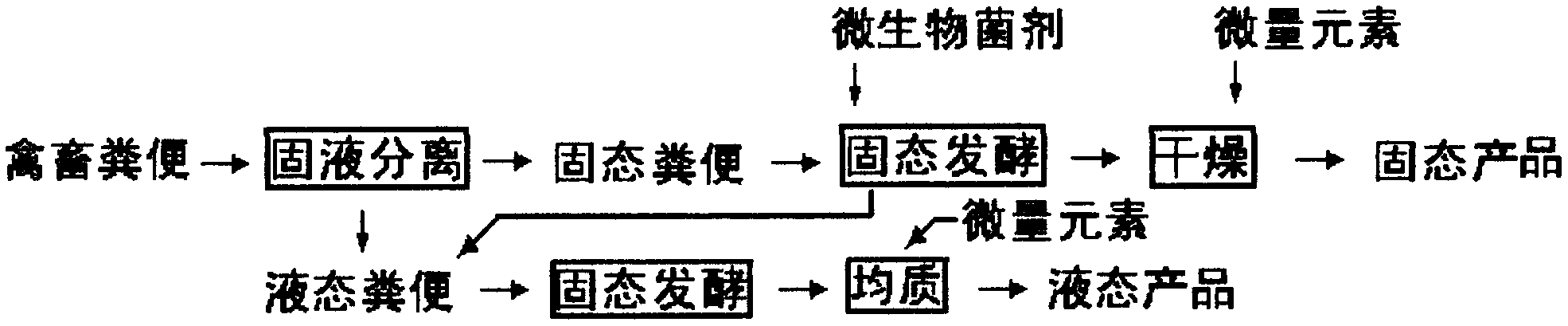

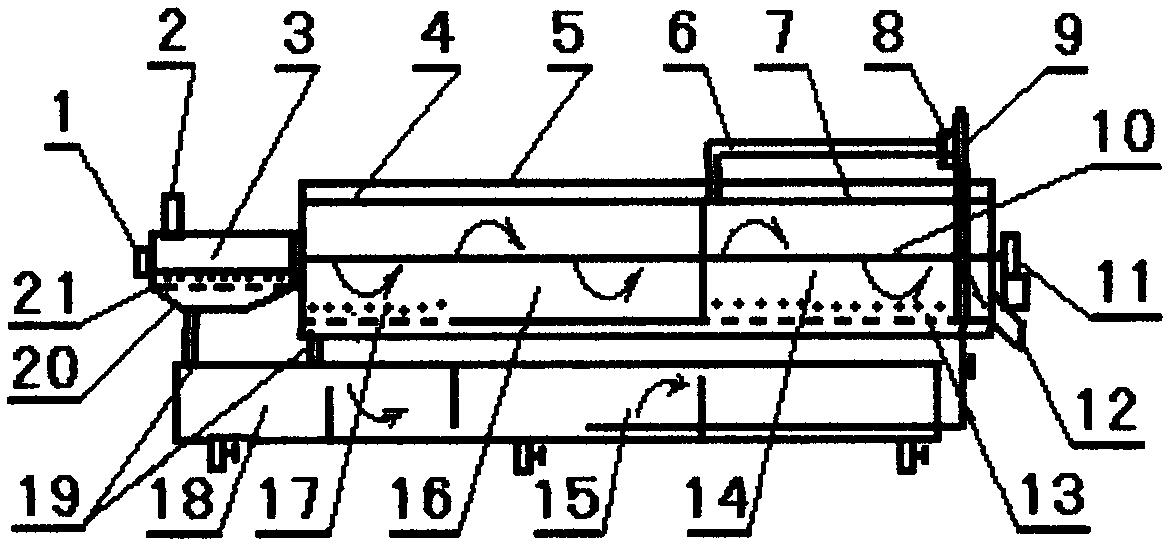

[0026] A method for the continuous production of solid and liquid organic fertilizers using pig manure. A solid-liquid separation unit, a solid-state fermentation unit, a drying unit, and a liquid-state fermentation unit are set up for pig manure. The process is: solid-liquid separation unit→solid-state fermentation→drying unit→ Solid product; solid-liquid separation unit solid → liquid fermentation unit → liquid product; solid-liquid separation unit, solid-state fermentation unit and drying unit are horizontally connected in series, and the feeding device continuously sends pig manure into the screw press, and the screw press performs pig manure Continuous extrusion, the separated solid pig manure continuously enters the solid fermenter for stirring and breaking up, the feeder of the solid fermenter continuously adds the special compound microbial agent for the harmless treatment of livestock and poultry manure, the stirring drive device drives the stirring shaft, and stirs the...

Embodiment 2

[0036] A method for continuously producing solid and liquid organic fertilizers by using mixed manure from chickens and cattle is characterized in that: a solid-liquid separation unit, a solid-state fermentation unit, a drying unit and a liquid fermentation unit are provided for the mixed manure from chickens and cattle, and the process is as follows: Liquid separation unit → solid-state fermentation → drying unit → solid product; solid-liquid separation unit solid state → liquid fermentation unit → liquid product; solid-liquid separation unit, solid-state fermentation unit and drying unit are horizontally connected in series, and the feeding device continuously mixes chicken and cow manure Feed into the screw press, and the screw press will continuously extrude the mixed manure of chicken and cow, and the separated solid mixed manure of chicken and cow will be continuously fed into the solid fermentation tank for stirring and breaking up, and the feeder of the solid fermentatio...

Embodiment 3

[0046] A method for continuously producing solid and liquid organic fertilizers from poultry manure, characterized in that: a solid-liquid separation unit, a solid-state fermentation unit, a drying unit and a liquid-state fermentation unit are set up for the livestock and poultry manure, and the process is: solid-liquid separation unit → solid state Fermentation→drying unit→solid product; solid-liquid separation unit solid state→liquid fermentation unit→liquid product; solid-liquid separation unit, solid-state fermentation unit and drying unit are horizontally connected in series, and the feeding device continuously feeds livestock and poultry manure into the screw press. The press machine continuously squeezes the livestock and poultry manure, and the separated solid livestock and poultry manure continuously enters the solid fermentation tank for stirring and breaking up. The device drives the stirring shaft to stir the solid livestock and poultry manure and the dry solid-stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com