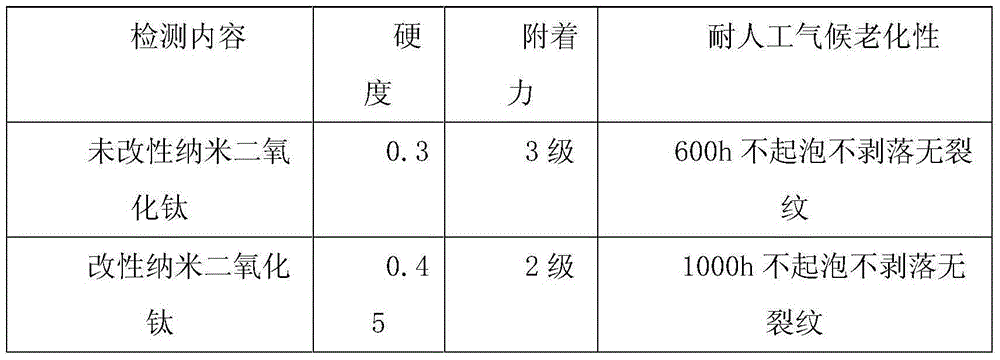

A modified nano-titanium dioxide with good dispersion and good anti-ultraviolet effect and its preparation method

A nano-titanium dioxide, anti-ultraviolet technology, applied in chemical instruments and methods, dyed low-molecular-weight organic compound treatment, fibrous fillers, etc. effect, increased dispersion effect, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] specific implementation plan

[0014] The present invention will be described in detail below through specific examples.

[0015] A modified nano-titanium dioxide with good dispersion and good anti-ultraviolet effect, prepared from the following raw materials in parts by weight (kg): nano-titanium dioxide 85, far-infrared ceramic powder 3, talc powder 2, crushed wood fiber 3, aluminum sulfate 1, Caprylic / Capric Triglyceride 1, Bone Glue 3.5, Sodium Hexametaphosphate 1, Dispersant NNO0.8, Acrylic-2-Hydroxypropyl Acrylate 4, Modified Silica 2;

[0016] The modified silicon dioxide is made of the following raw materials in parts by weight (kg): silicon dioxide 55, nano jade powder 6, white corundum powder 5, silane coupling agent kh5601, nano barium sulfate 2, acrylic acid-2-hydroxy Ethyl fat 3, dimethyl fumarate 3, cobalt naphthenate 2, water 50; the preparation method is to first add nano silicon dioxide, nano jade powder, silane coupling agent kh560, nano barium sulfat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com