Light-aging-resistant latex product and manufacturing method thereof

A latex product, anti-light aging technology, applied in the field of latex product manufacturing, can solve the problems of easy yellowing, slag in the incision, surface cracking, etc., and achieve good light and heat stability, no odor, and good biological properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

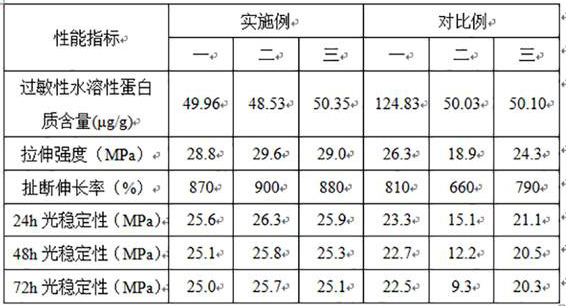

Examples

Embodiment 1

[0024] 80 parts, 12 parts of nano filler, 1 part of vulcanization accelerator, 3 parts of polyethylene glycol dimethacrylate, 2 parts of ethylene glycol monostearate, 1 part of butyl stearate, cetyl tri 1 part of methyl ammonium bromide;

[0025] Among them, the nano-filler is prepared by the following method: (1) According to the mass ratio of 3:1:18, alumina and titanium dioxide are added to water, and the dispersion is obtained after ultrasonic dispersion for 20 minutes, and sodium alginate with 15% of the total amount of the dispersion is added Stir and mix for 1 hour to obtain a mixed solution; (2) Put the mixed solution in a high-temperature calcination device, and in a nitrogen atmosphere, at a high temperature of 1000°C, calcine for 1 hour, and cool down after calcination to obtain a calcined powder; (3) press The mass ratio is 1:7, the calcined powder is added to the ethanol aqueous solution with a concentration of 32%. The mass ratio of ethoxysilane and sulphenone i...

Embodiment 2

[0032] A kind of anti-aging latex product proposed by the present invention comprises the following raw materials in parts by weight: 90 parts of natural latex, 15 parts of nano fillers, 3 parts of vulcanization accelerator, 5 parts of polyethylene glycol dimethacrylate, ethylene dimethacrylate 3 parts of alcohol monostearate, 2 parts of butyl stearate, 2 parts of cetyltrimethylammonium bromide;

[0033] Among them, the nano-filler is prepared by the following method: (1) According to the mass ratio of 4:2:25, alumina and titanium dioxide are added to water, and the dispersion is obtained after ultrasonic dispersion for 25 minutes, and sodium alginate with 18% of the total amount of the dispersion is added Stir and mix for 1.5 hours to obtain a mixed solution; (2) Put the mixed solution in a high-temperature calcination device, and calcine it for 1.5 hours at a high temperature of 1050°C under a nitrogen atmosphere, and cool down after calcination to obtain a calcined powder; (...

Embodiment 3

[0040] A kind of anti-photoaging latex product proposed by the present invention comprises the following raw materials in parts by weight: 100 parts of natural latex, 18 parts of nano fillers, 5 parts of vulcanization accelerator, 7 parts of polyethylene glycol dimethacrylate, ethylene dimethacrylate 4 parts of alcohol monostearate, 3 parts of butyl stearate, 3 parts of cetyltrimethylammonium bromide;

[0041] Among them, the nano-filler is prepared by the following method: (1) According to the mass ratio of 5:3:32, alumina and titanium dioxide are added to water, and the dispersion is obtained after ultrasonic dispersion for 30 minutes, and sodium alginate with a total amount of 22% of the dispersion is added Stir and mix for 2 hours to obtain a mixed solution; (2) Put the mixed solution in a high-temperature calcination device, and calcine it for 2 hours at a high temperature of 1100°C under a nitrogen atmosphere, and cool down after calcination to obtain a calcined powder; (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com