Jet device for supercritical fluid jet dyeing of yarns

A supercritical fluid and ejector technology, which can be used in spray/jet textile material processing, liquid/gas/vapor jet propulsion fabrics, liquid/gas/vapor processing indefinite-length textile materials, etc., can solve the problem of increasing the complexity of the device structure and Investment cost, inability to achieve large-scale continuous dyeing of dyed objects, high sealing requirements, etc., to achieve the effects of good levelness and continuity, tight structure, safe and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

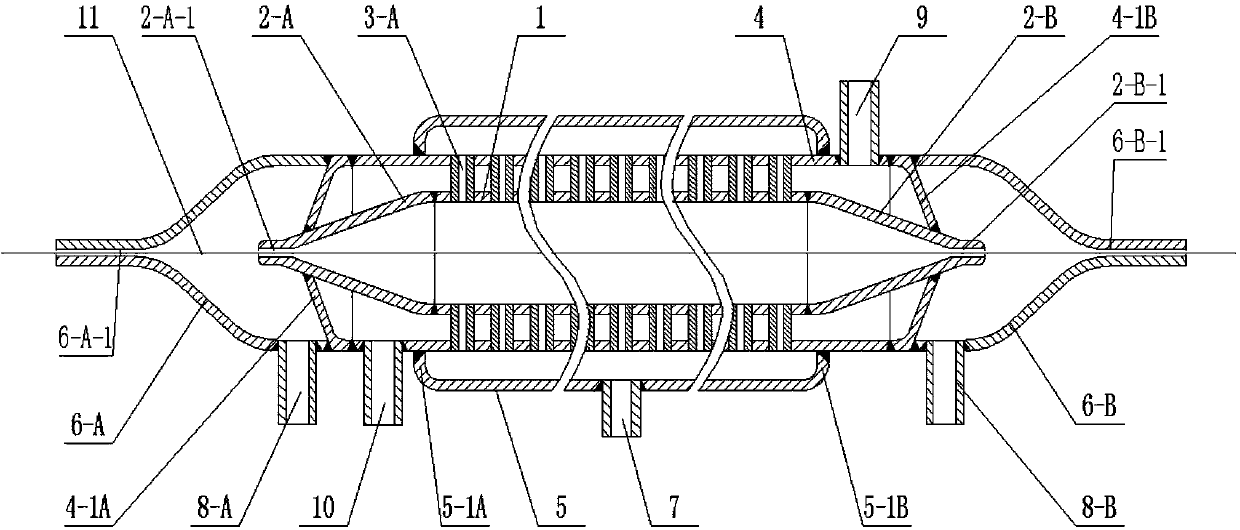

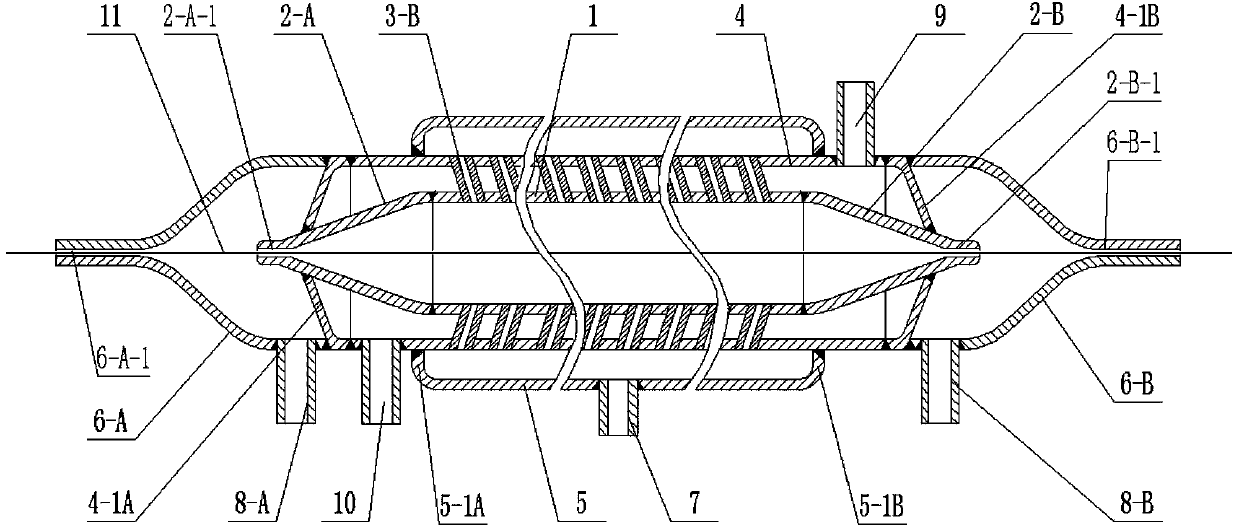

[0020] Embodiment one, the supercritical fluid jet dyeing yarn injector with heating tube is made of stainless steel material, such as figure 1 , figure 2 , image 3 and Figure 4 shown.

[0021] Depend on The spray hole distribution pipe 1, the big end and little endian The high pressure guide nozzle 2-A and 2-B, The heating pipe 4 and the heating pipe plug 4-1A and 4-1B, The fluid distribution pipe 5 and the fluid distribution pipe plugs 5-1A and 5-1B, the big end and little endian Low-pressure guide nozzles 6-A and 6-B, Directly installed orifice pipe 3-A or obliquely installed orifice pipe 3-B, Fluid inlet connection 7, Fluid outlet connections 8-A and 8-B, Steam inlet connection 9 and The steam outlet connecting pipe 10 is composed of; the number of spray holes is determined to be 12 according to the specific dyeing process conditions; the two ends of the spray hole distribution pipe 1 are coaxially welded and connected to the high-pressure guide...

Embodiment 2

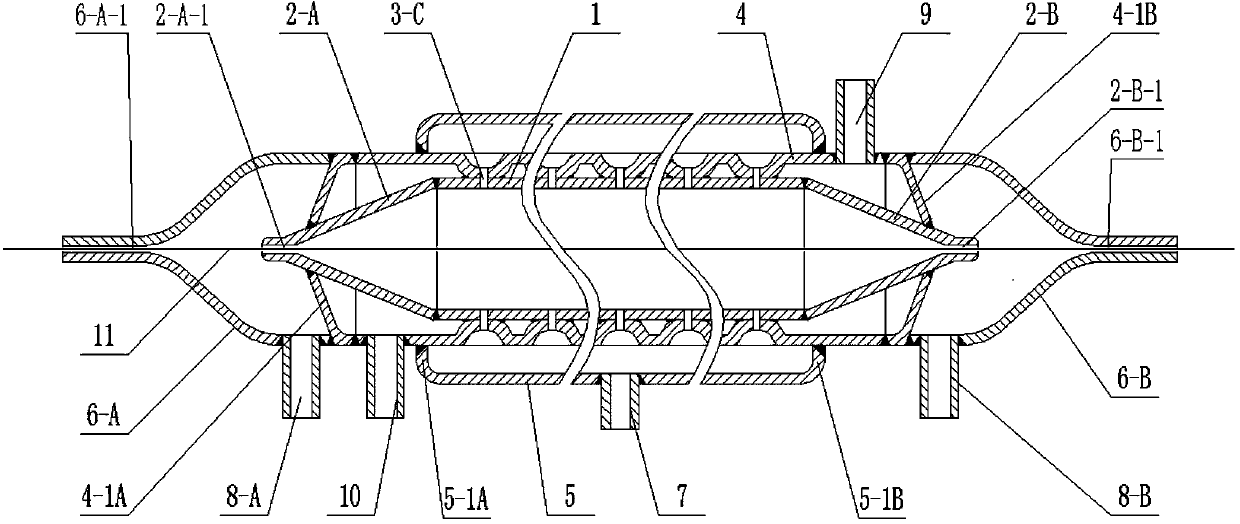

[0032] Embodiment two, the supercritical fluid jet dyeing yarn injector without heating tube is made of stainless steel, such as Figure 4 and Figure 5 shown.

[0033] Depend on The spray hole distribution pipe 1, the big end and little endian The high pressure guide nozzle 2-A and 2-B, The fluid distribution pipe 5 and the fluid distribution pipe plugs 5-1A and 5-1B, the big end and little endian Low-pressure guide nozzles 6-A and 6-B, The fluid inlet connection 7, The fluid outlet connecting pipes 8-A and 8-B are formed; the number of spray holes is determined to be 15 according to the specific dyeing process conditions, and the two ends of the spray hole distribution pipe 1 are coaxially welded and connected to the high-pressure guide nozzles 2-A and 2- B, Drilling on nozzle distribution pipe 1 The small holes are divided into 5 circles, and 3 are evenly distributed in each circle. The distance between each circle and the outermost circle and the high-pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com