A method for producing rutile titanium dioxide for decorative laminated paper

A rutile type titanium dioxide, production method technology, applied in the direction of titanium dioxide, pigment-containing coating, titanium oxide/hydroxide, etc., can solve the problems of poor light fastness of laminated paper, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

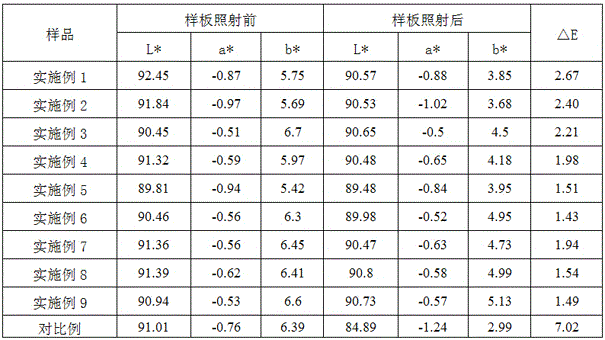

Examples

Embodiment 1

[0025] The preparation method of the rutile type titanium dioxide for the decorative laminated paper of this embodiment comprises the following main steps:

[0026] (1) Weigh 6000g of deionized water and add 12g of SiO 2 Sodium silicate solution, add 4000g uncoated rutile titanium dioxide under stirring to make a concentration of about 600 gTiO 2 / L of titanium dioxide slurry, and then sanded with a sand mill to make the titanium dioxide reach the original particle size.

[0027] (2) Use deionized water to dilute the concentration of the qualified titanium dioxide slurry to 200gTiO 2 / L, and then transferred to the coating tank, and the temperature of the slurry was raised to 40°C by indirect steam heating.

[0028] (3) Add a concentration of 80g SiO to the diluted slurry 2 / L of sodium silicate solution, after adding SiO 2 with TiO 2 The mass percentage is about 2.0%; then adjust the pH value of the slurry to 6.0 with a dilute sulfuric acid solution with a mass percentag...

Embodiment 2

[0035] (1) Weigh 6000g of deionized water and add 12g of SiO 2 Sodium silicate solution, add 5000g uncoated rutile titanium dioxide under stirring to make a concentration of about 700 gTiO 2 / L of titanium dioxide slurry, and then sanded with a sand mill to make the titanium dioxide reach the original particle size.

[0036] (2) Dilute the concentration of the sand-milled titanium dioxide slurry to 300gTiO with deionized water 2 / L, and then transferred to the coating tank, and the temperature of the slurry was raised to 60°C by indirect steam heating.

[0037] (3) Add a concentration of 100g SiO to the diluted slurry 2 / L of sodium silicate solution, after adding SiO 2 with TiO 2 The mass percentage is about 3.0%; then adjust the pH value of the slurry to 7.0 with a dilute sulfuric acid solution with a mass percentage concentration of 15%; stir and mature for 1 hour.

[0038] (4) Adjust the pH value of the slurry to between 10.0 and 10.5 with dilute alkali within 20 minu...

Embodiment 3

[0044] (1) Weigh 6000g of deionized water and add 12g of SiO 2 Sodium silicate solution, add 6000g uncoated rutile titanium dioxide under stirring to make a concentration of about 800 gTiO 2 / L of titanium dioxide slurry, and then sanded with a sand mill to make the titanium dioxide reach the original particle size.

[0045] (2) Use deionized water to dilute the concentration of the qualified titanium dioxide slurry to 400gTiO 2 / L, and then transferred to the coating tank, and the temperature of the slurry was raised to 90°C by indirect steam heating.

[0046] (3) Add a concentration of 120g SiO to the diluted slurry 2 / L of sodium silicate solution, after adding SiO 2 with TiO 2 The mass percentage is about 4.0%; then adjust the pH value of the slurry to 8.0 with a dilute sulfuric acid solution with a mass percentage concentration of 15%; stir and mature for 1 hour.

[0047] (4) Adjust the pH value of the slurry to between 10.0 and 10.5 with dilute alkali within 20 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com