Patents

Literature

38 results about "Lamination paper" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lamination paper is a paper used for laminates. Normally on particle or fiberboards giving a good-looking and resistant surface for use as furniture, decoration panels and flooring.

Process of making a water dispersible titanium dioxide pigment useful in paper laminates

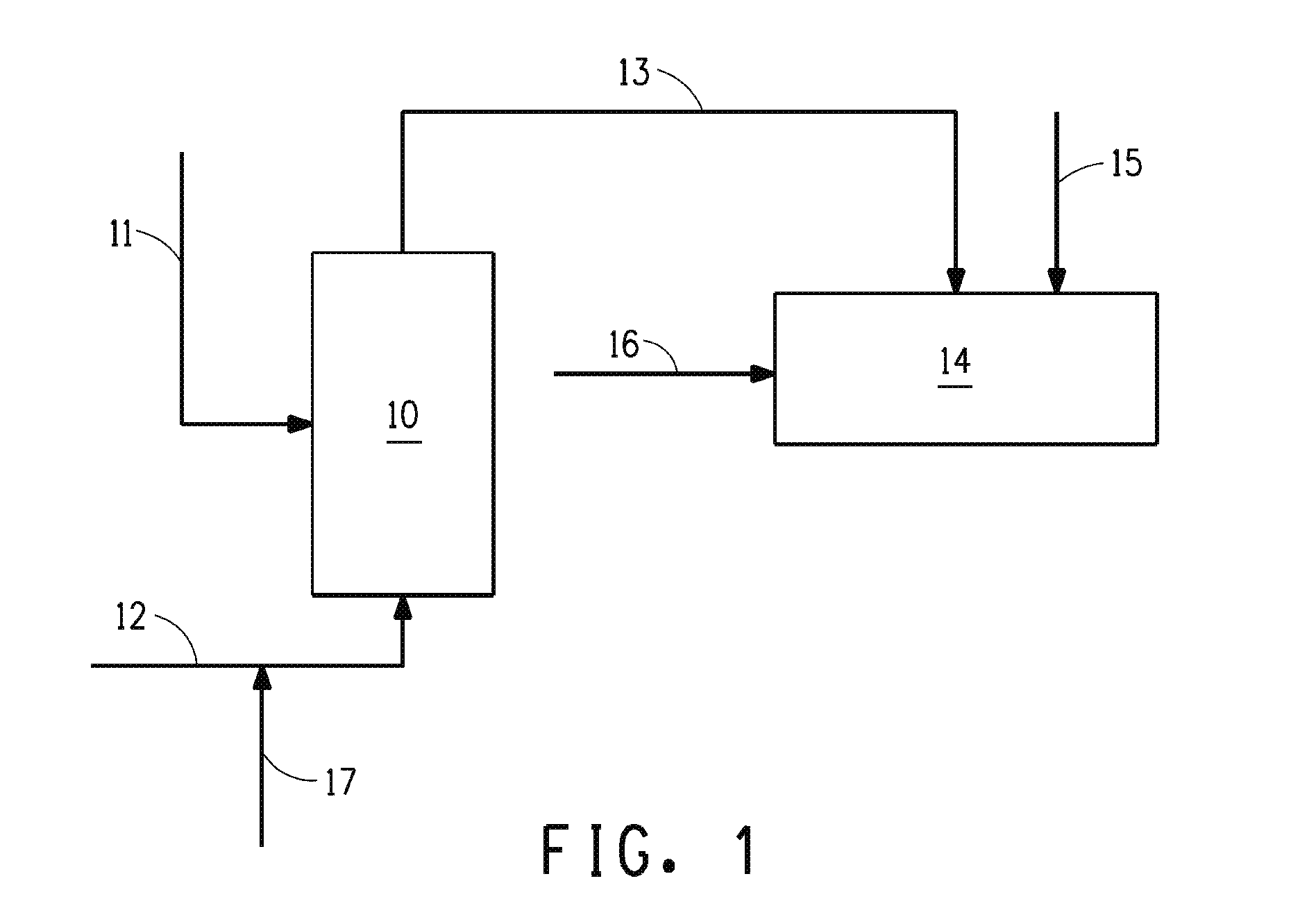

The present invention relates to a process for making a titanium dioxide pigment having consisting of titanium dioxide and single layer of inorganic surface treatment consisting of aluminum phosphate wherein the pigment is characterized by and isoelectric point which is greater than pH 6 and a negative zeta potential of at a pH of 7.5 or more.

Owner:EI DU PONT DE NEMOURS & CO

Method of producing a paper product

ActiveUS20100024998A1Protected contentNon-fibrous pulp additionPaper after-treatmentPolymer scienceCellulose fiber

The invention relates to a method of producing a laminate paper product comprising at least two layers, said method comprising (i) providing an aqueous suspension comprising cellulosic fibers (ii) adding to the suspension microfibrillar polysaccharide in an amount to yield from about 0.05 to about 50 wt % based on the weight of the cellulosic fibers (iii) dewatering the obtained suspension and forming a first layer having a density from about 150 to about 500 kg / m3 of said laminate paper product. The invention also relates to a method comprising (i) providing an aqueous suspension comprising cellulosic fibers (ii) adding to the suspension microfibrillar polysaccharide in an amount to yield from about 0.05 to about 50 wt % based on the weight of the cellulosic fibers (iii) dewatering the obtained suspension and forming at least a first and a second layer of said laminate whereby at least one of said at least first and second layer is formed from an aqueous suspension obtained in step (ii) containing microfibrillar polysaccharide; and joining said layers in such way that the laminate product obtains a density from about 150 to about 800 kg / m3. The invention also relates to a laminate paper product which can be obtained by the method and the use thereof.

Owner:KEMIRA OY

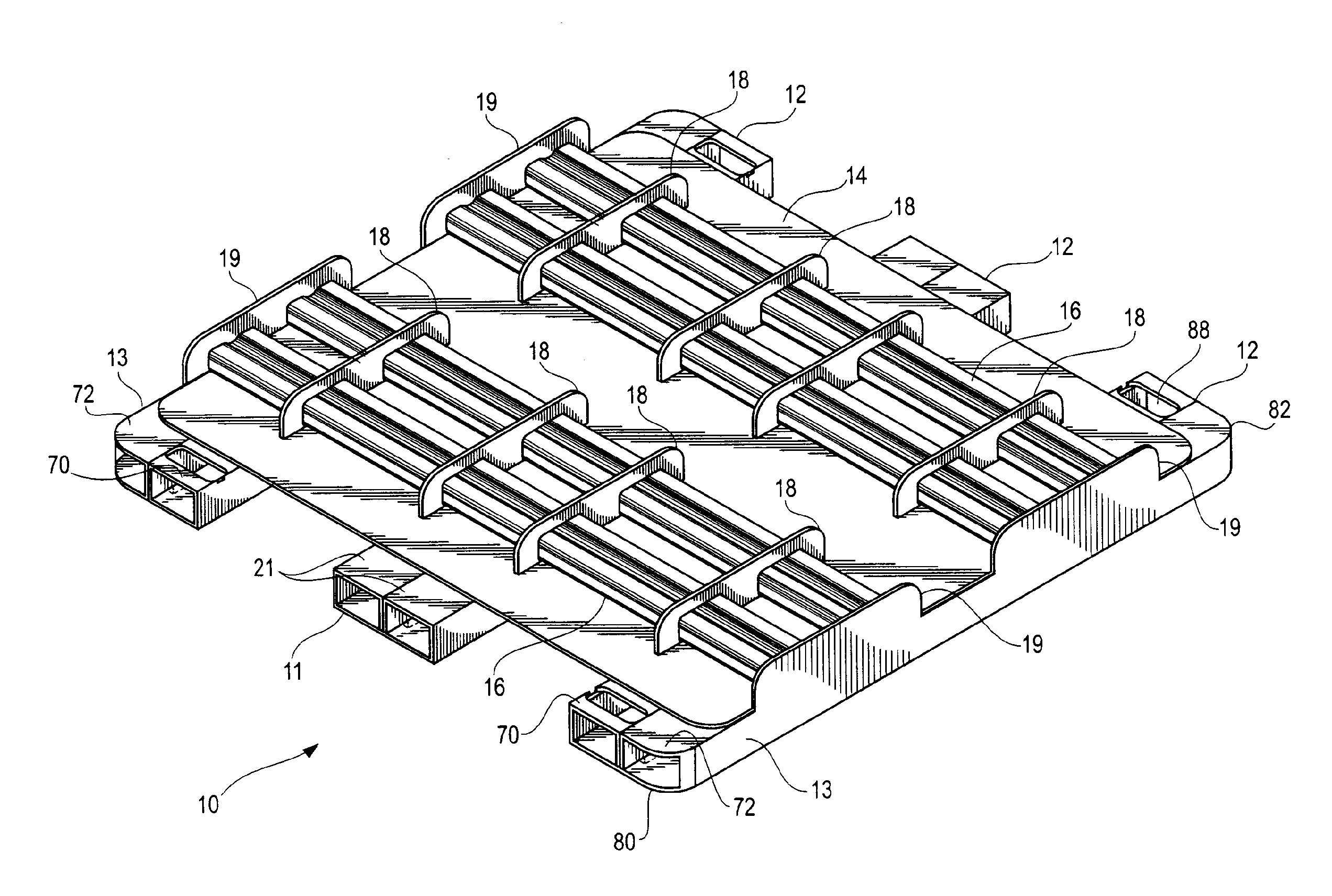

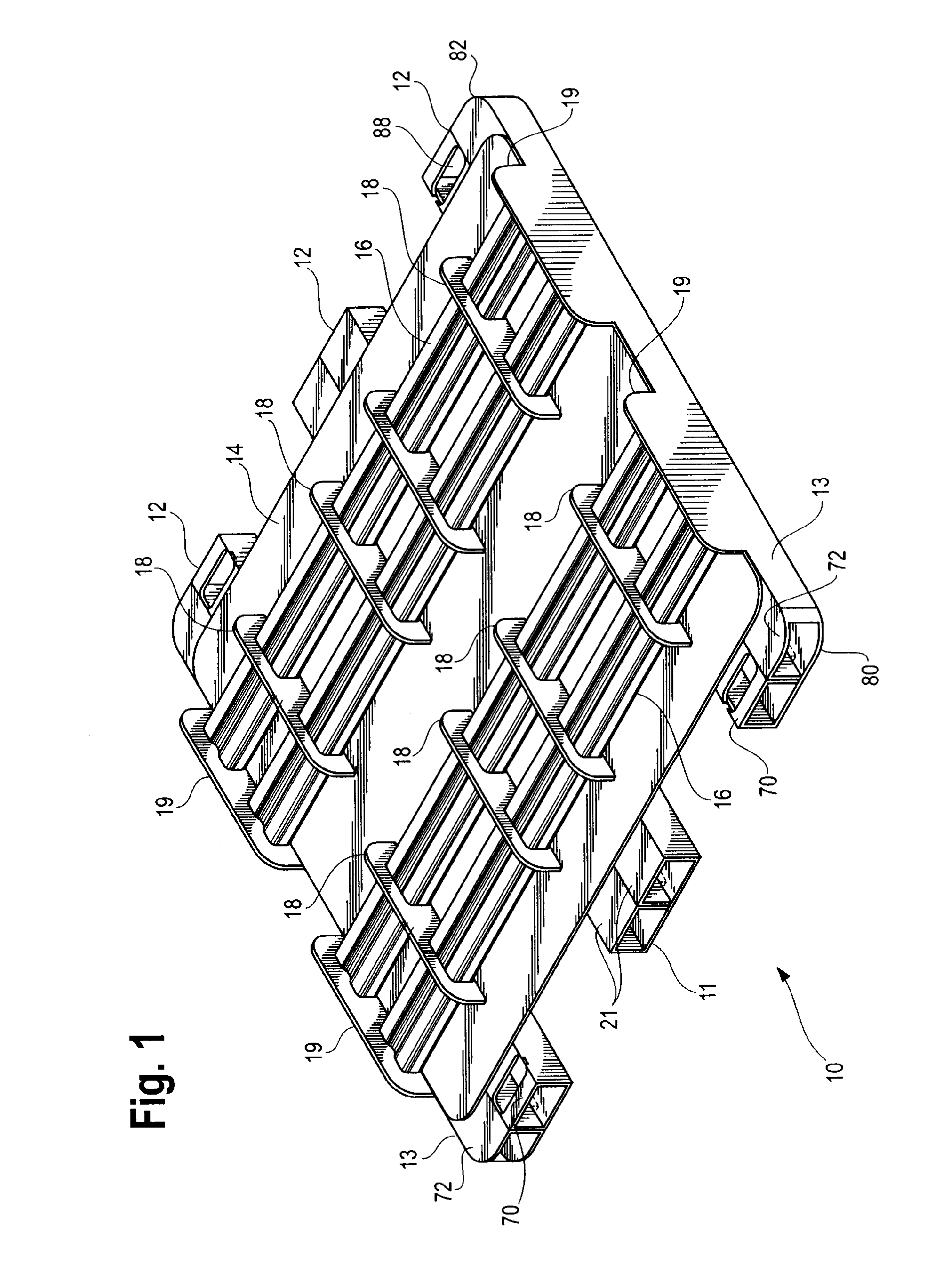

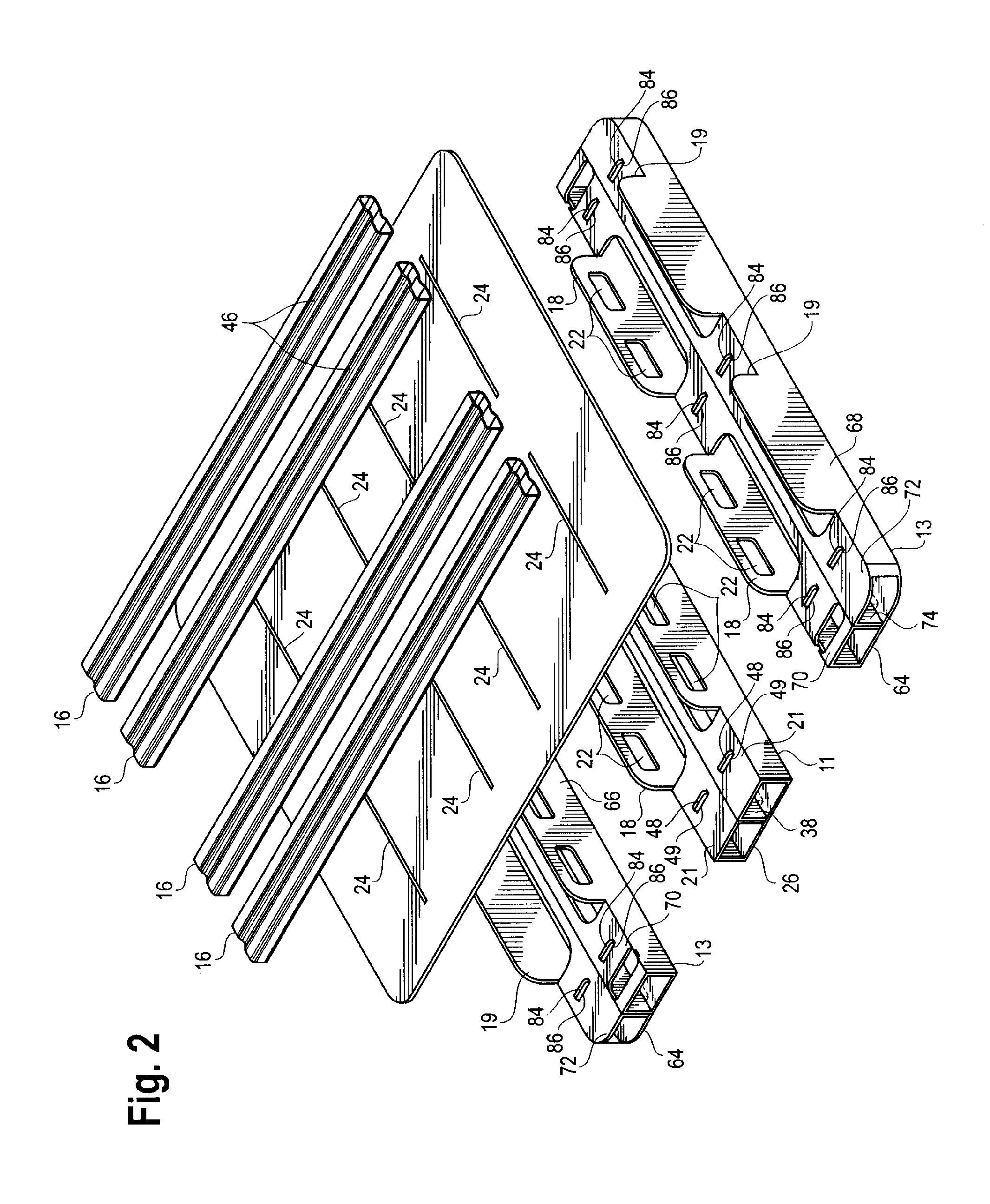

Single use disposable pallet

A single use disposable, recyclable paper pallet for supporting products during storage and shipping is provided. The pallet comprises a corrugated panel resting on multiple, parallel corrugated runners locked together by lateral supports. The runners are made from blanks folded into elongated open-ended box-like shapes. The folded runners have perforated tabs that extend upwards from the top surface of the runners and configured to receive the lateral supports. The lateral supports are formed from a sheet of convolutely wound, formed laminated paper and provide lateral strength so the pallet can be handled with a clamp truck.

Owner:SONOCO DEV INC

Method of producing a paper product

The invention relates to a method of producing a laminate paper product comprising at least two layers, said method comprising (i) providing an aqueous suspension comprising cellulosic fibers (ii) adding to the suspension microfibrillar polysaccharide in an amount to yield from about 0.05 to about 50 wt % based on the weight of the cellulosic fibers (iii) dewatering the obtained suspension and forming a first layer having a density from about 150 to about 500 kg / m3 of said laminate paper product. The invention also relates to a method comprising (i) providing an aqueous suspension comprising cellulosic fibers (ii) adding to the suspension microfibrillar polysaccharide in an amount to yield from about 0.05 to about 50 wt % based on the weight of the cellulosic fibers (iii) dewatering the obtained suspension and forming at least a first and a second layer of said laminate whereby at least one of said at least first and second layer is formed from an aqueous suspension obtained in step (ii) containing microfibrillar polysaccharide; and joining said layers in such way that the laminate product obtains a density from about 150 to about 800 kg / m3. The invention also relates to a laminate paper product which can be obtained by the method and the use thereof.

Owner:KEMIRA OY

Method for producing rutile titanium white powder applied to decorative laminated paper

ActiveCN104179066AGood weather resistanceMeets high light fastness requirementsCoatings with pigmentsTitanium dioxideWeather resistanceZirconium compounds

The invention discloses a method for producing rutile titanium white powder applied to decorative laminated paper. The method for producing the rutile titanium white powder applied to the decorative laminated paper comprises the following steps: preparing titanium white powder primary pulp, diluting, coating silicon-containing compounds, coating aluminum-containing compounds, curing, filtering, rinsing, drying, calcining, crushing and the like. According to the method for producing the rutile titanium white powder applied to the decorative laminated paper, the surface of the titanium white powder is firstly coated with a silicon film and subsequently coated with an aluminum film, so that the weather resistance of the titanium white powder is greatly improved; meanwhile, hydroxyl groups on the coated films are removed by using a manner of calcining and heating; the reaction of electron pairs is avoided; the requirement of high light resistance on the titanium white powder in the field of the decorative laminated paper can be met, so that the low-cost silicon compounds can be used for replacing zirconium compounds, phosphate, rare earth metals and the like for producing the titanium white powder with high light resistance applied to the decorative laminated paper.

Owner:XIANGYANG LOMON TITANIUM IND CO LTD

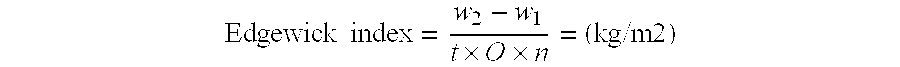

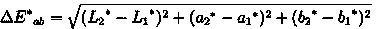

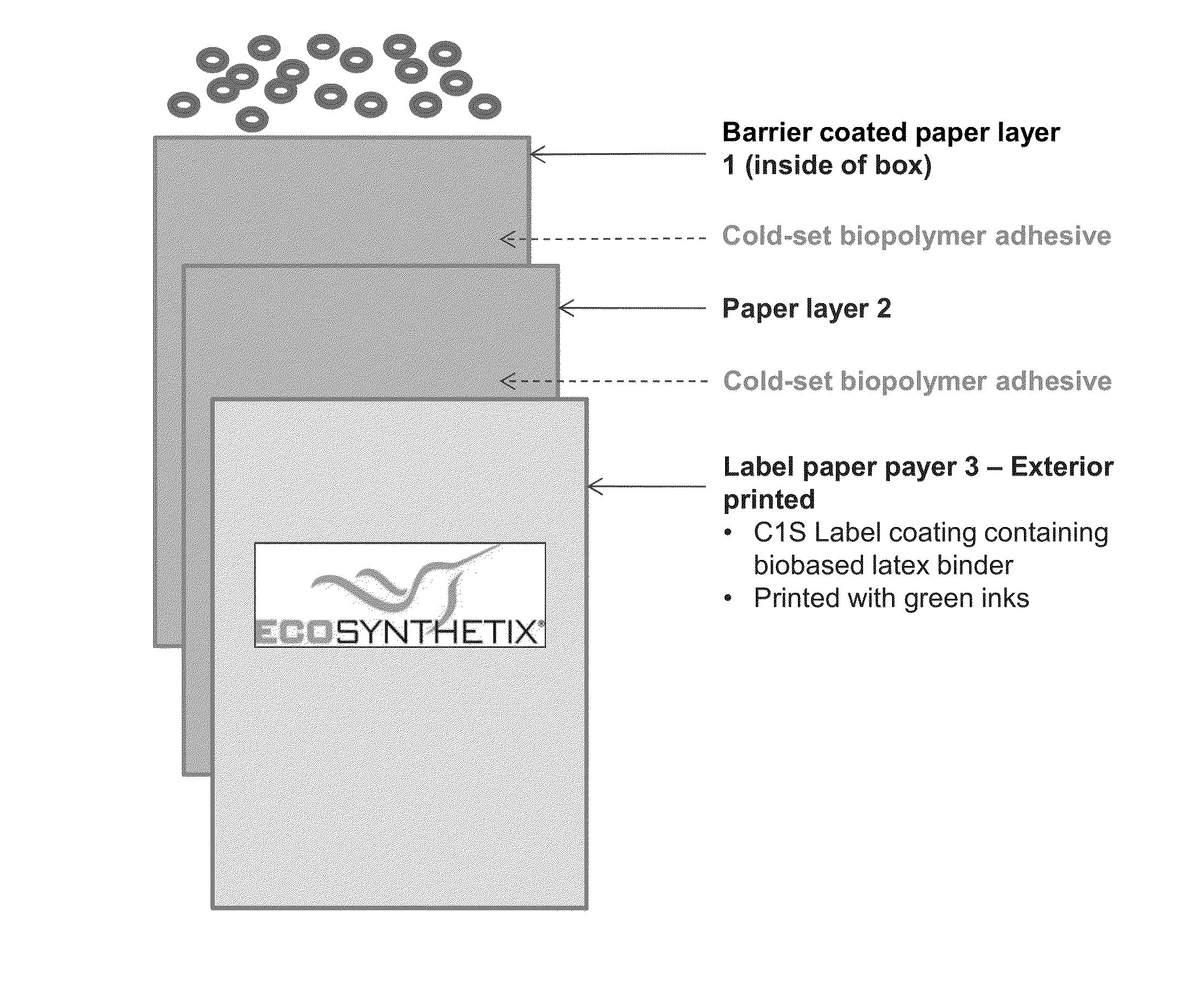

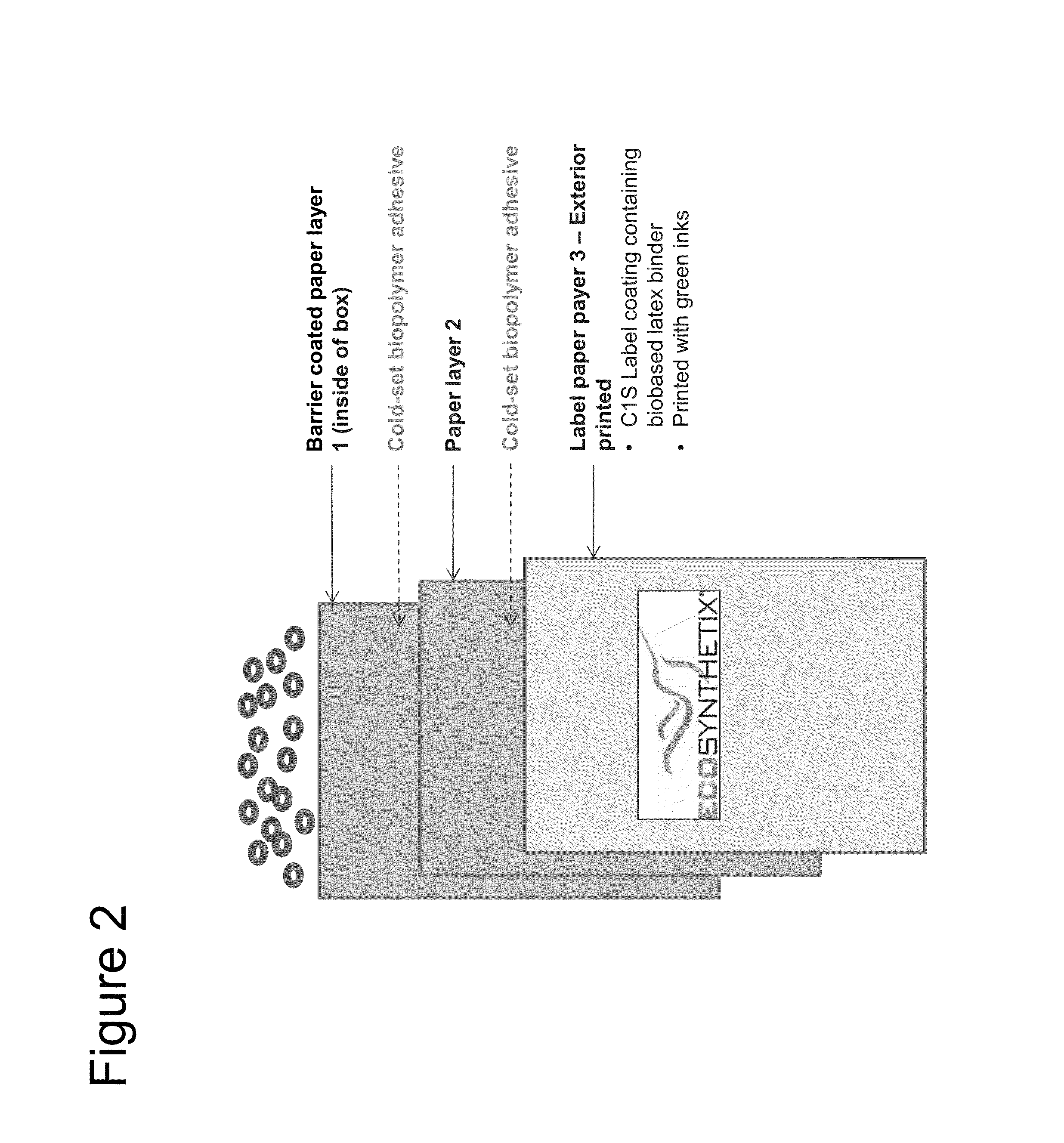

Cold-set biobased laminating adhesive for paper or paperboard products, and packaging materials

InactiveUS20160194527A1Non-macromolecular adhesive additivesStarch derivtive adhesivesFiberPaper recycling

This specification relates to cold-set biobased adhesive compositions, comprising aqueous formulations of biopolymers, optionally with alkaline additives, optionally fortified with high-aspect-ratio inorganic and organic fillers, fibers and nanofibers, optionally with barrier-inducing additives. The adhesive may be used, for example, as a cold-set, preferably biobased, laminating adhesive. In particular, the laminating adhesive may be used to create liner and / or medium paperboard products for light-weight paperboard and corrugated boxboard materials that, in some examples, have enhanced strength and / or barrier properties as compared with similar weight paperboard products. These laminated paperboard and corrugated boxboard materials are used, for example, as light weight packaging materials that are compatible with paper recycling and composting operations. In the context of this abstract, the term “lamination” or “laminating” relates to the adhesion of two flat (rather than pre-corrugated) paper surfaces, i.e. the gluing together of two continuous sheets of paper or liner or medium paperboard.

Owner:ECOSYNTHETIX INC

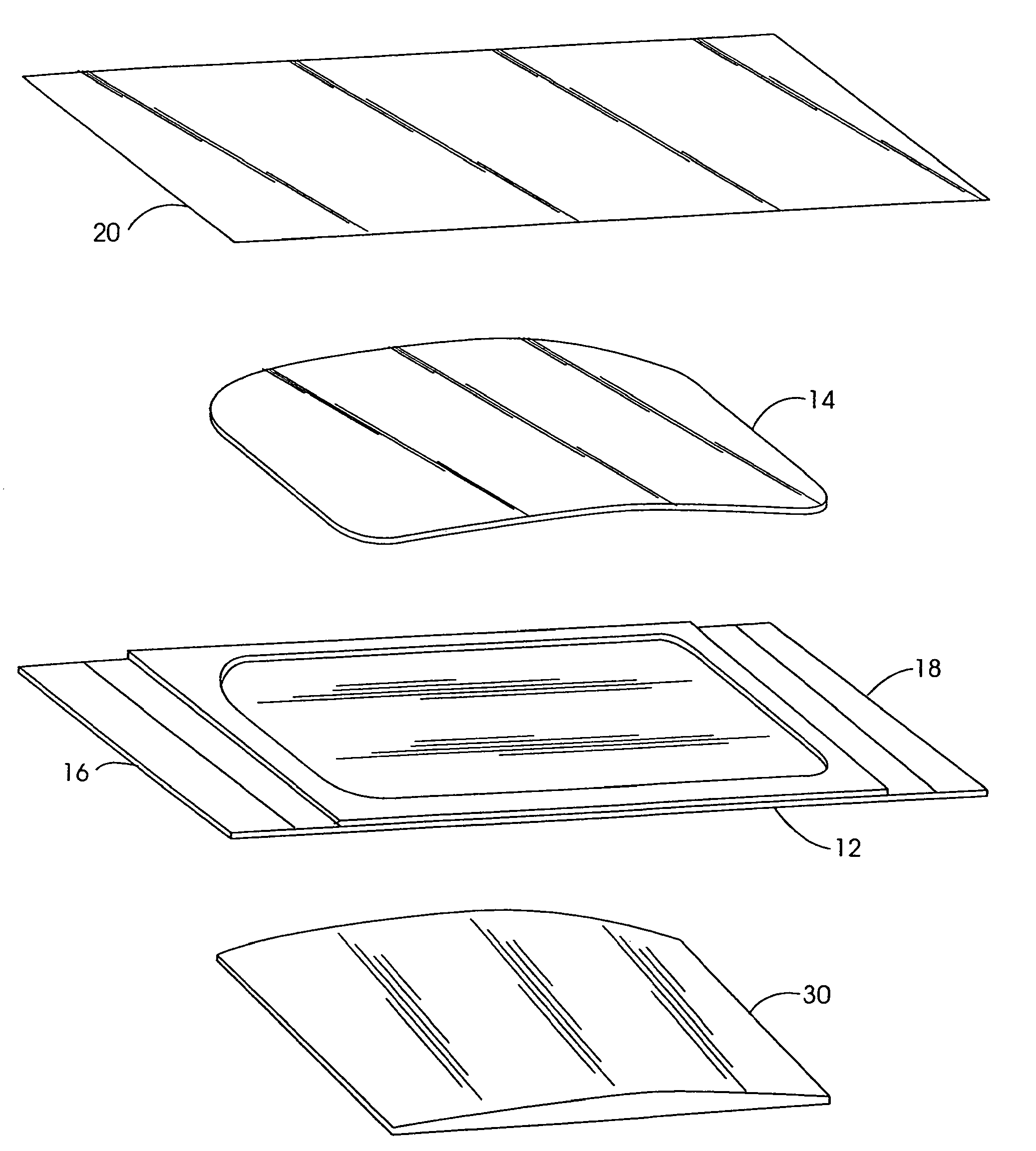

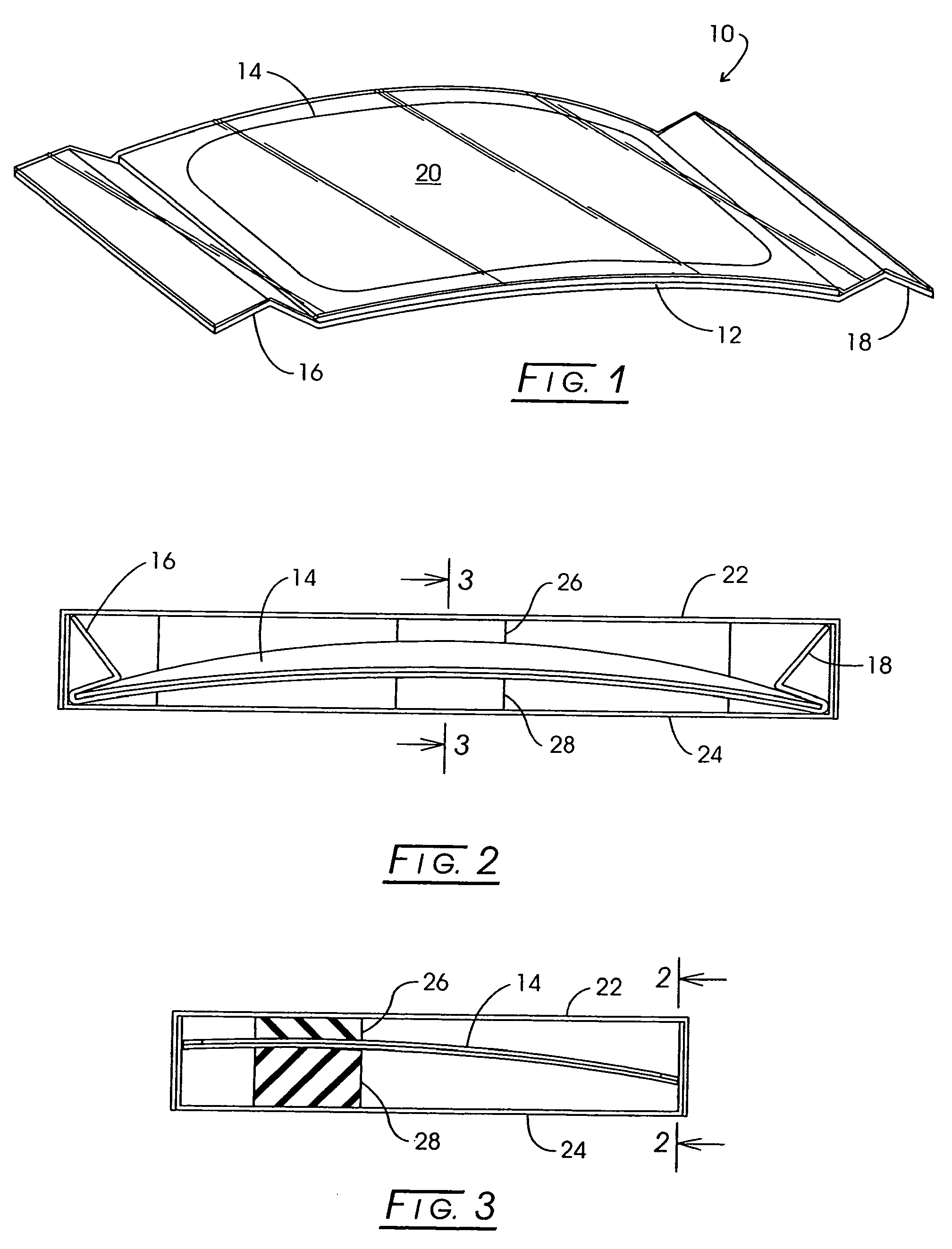

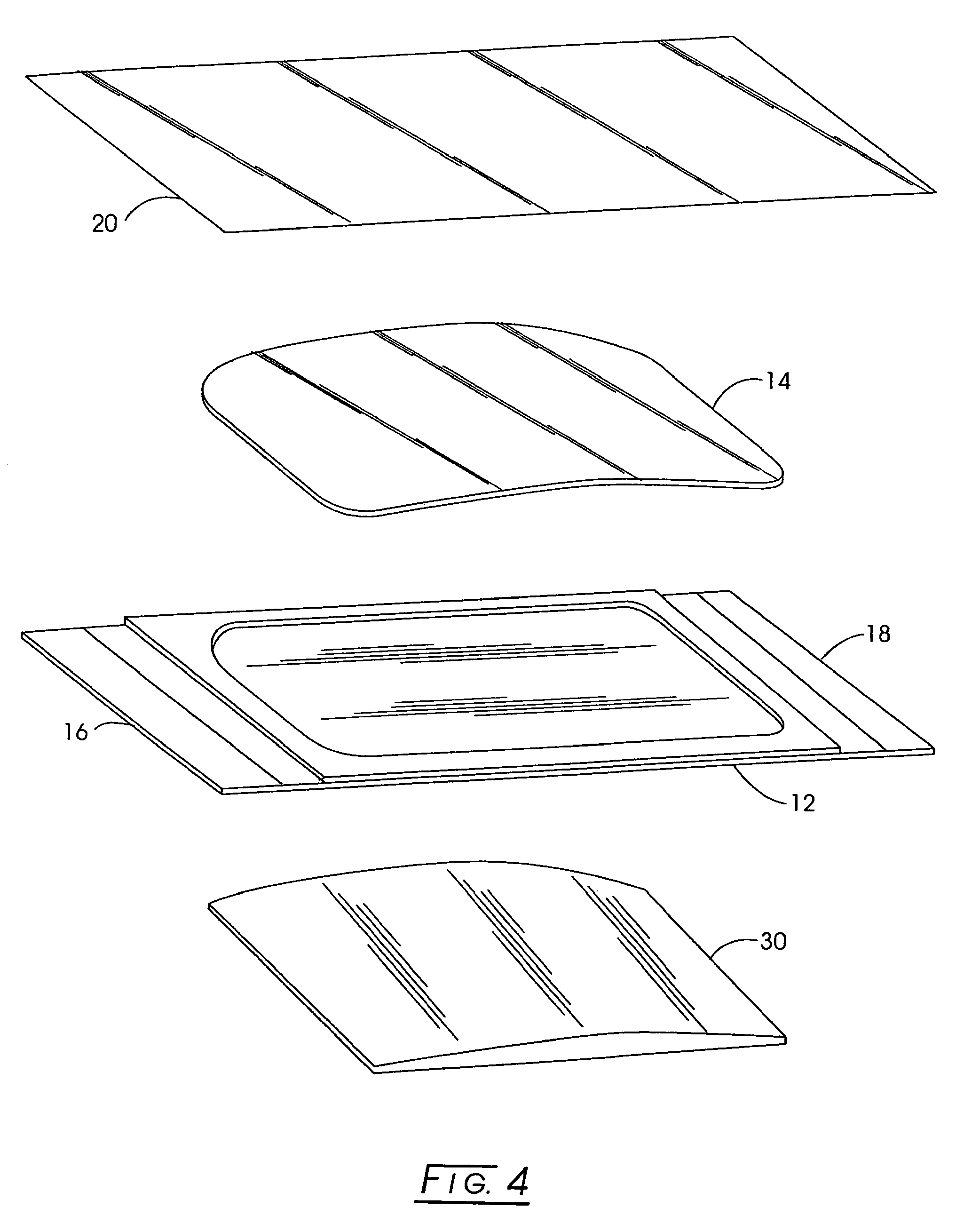

Automobile part shipping system and method

Plies of paperboard are laminated to form a paperboard laminate having a front and a back. An automobile part is placed on the front of the paperboard laminate leaving exposed the front of the paperboard laminate. The automobile part and the exposed paperboard laminate are shrink-wrapped with plastic shrink-wrap material. For automobile window glass, some of the front side plies of the paperboard laminate have been cut out to form a cavity in the configuration of the glass product being packaged. The glass product is disposed in the cavity and a glass product conforming reinforcing block is placed against the backside of the paperboard laminate during the shrink-wrap operation. For automobile fenders, hoods, the paperboard laminate need not be cut out and the sides of the paperboard laminate are folded upwardly to form a carton bottom to which a lid is affixed for shipping.

Owner:DRYIP

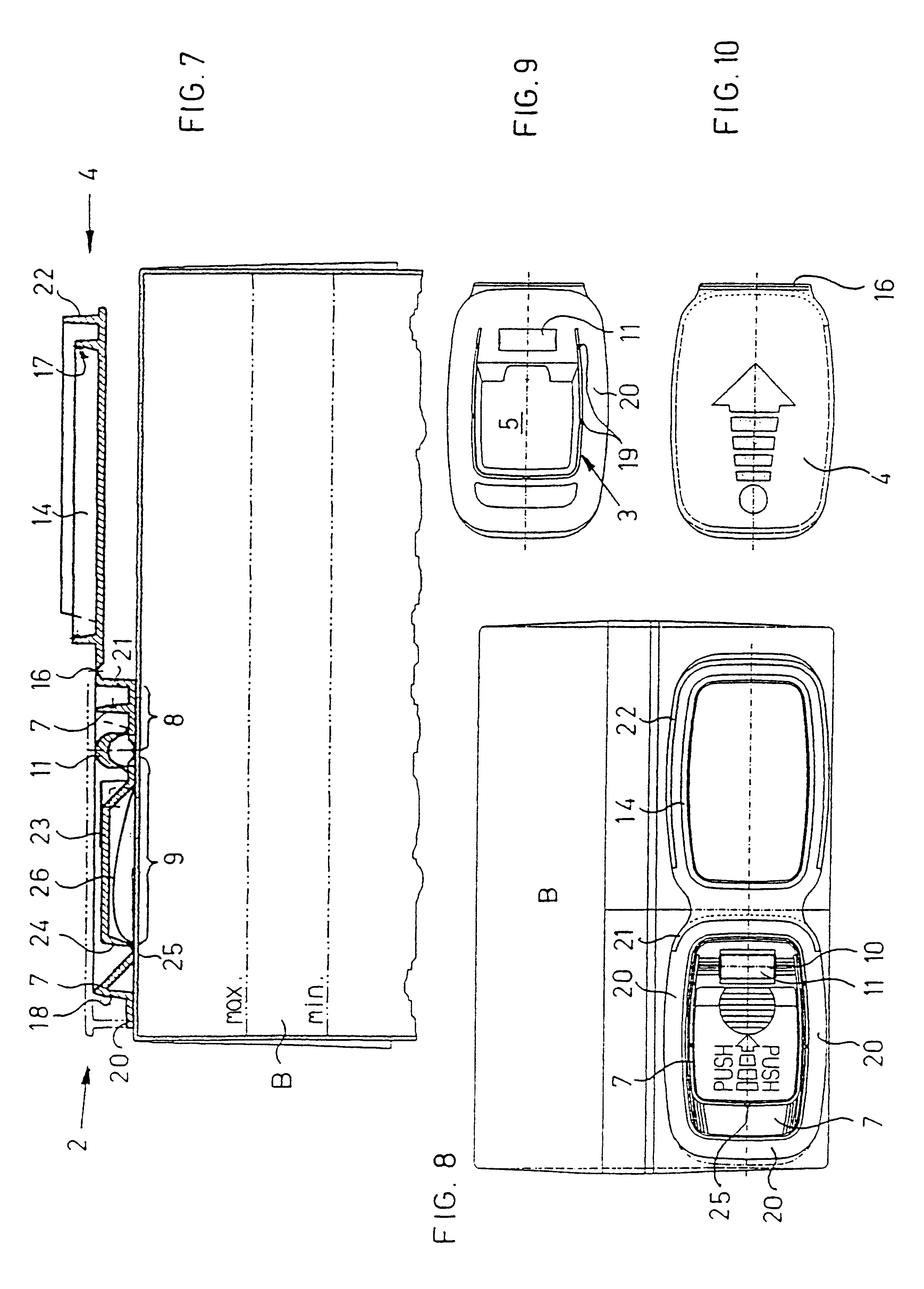

Closing device

Owner:TERXO

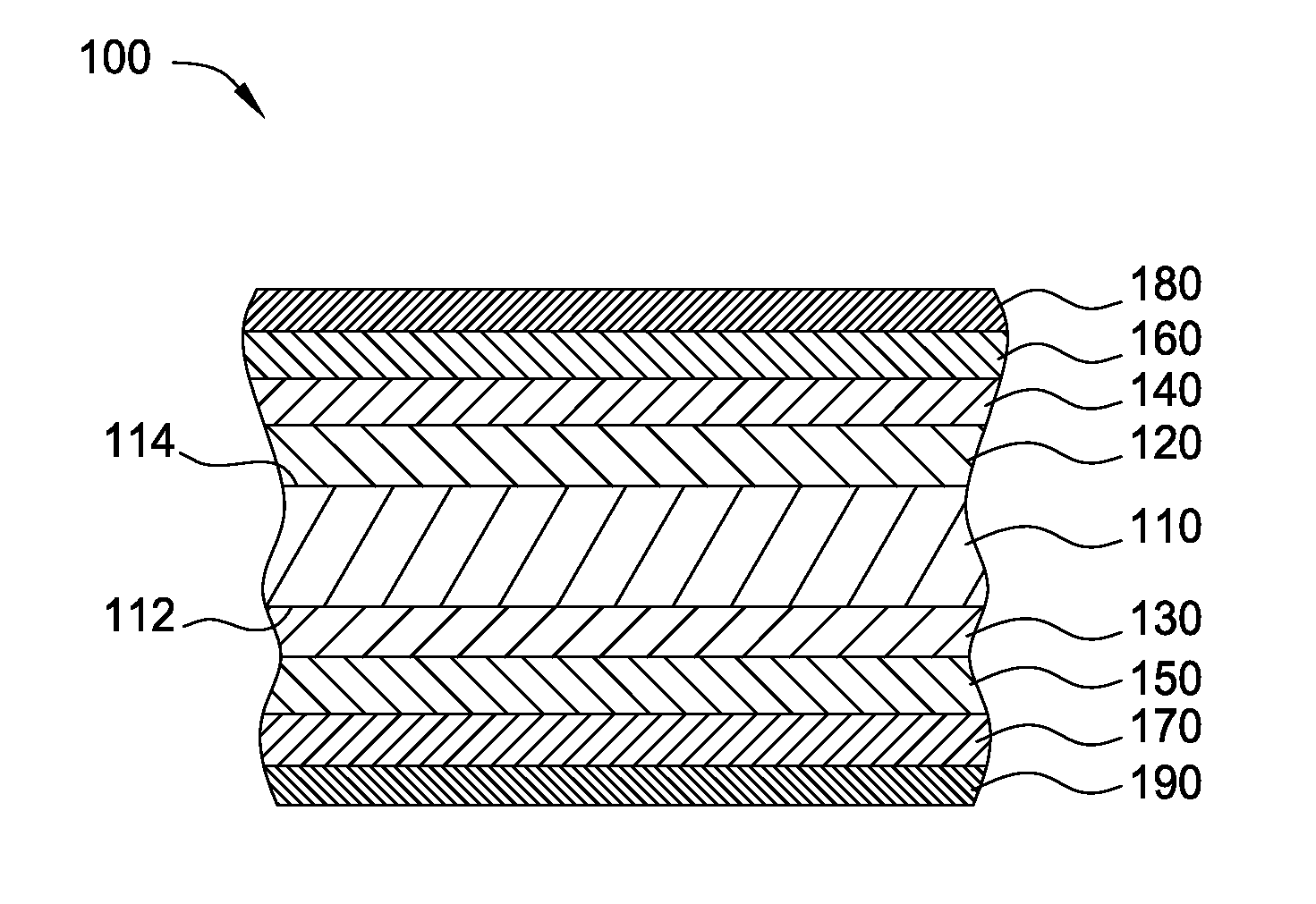

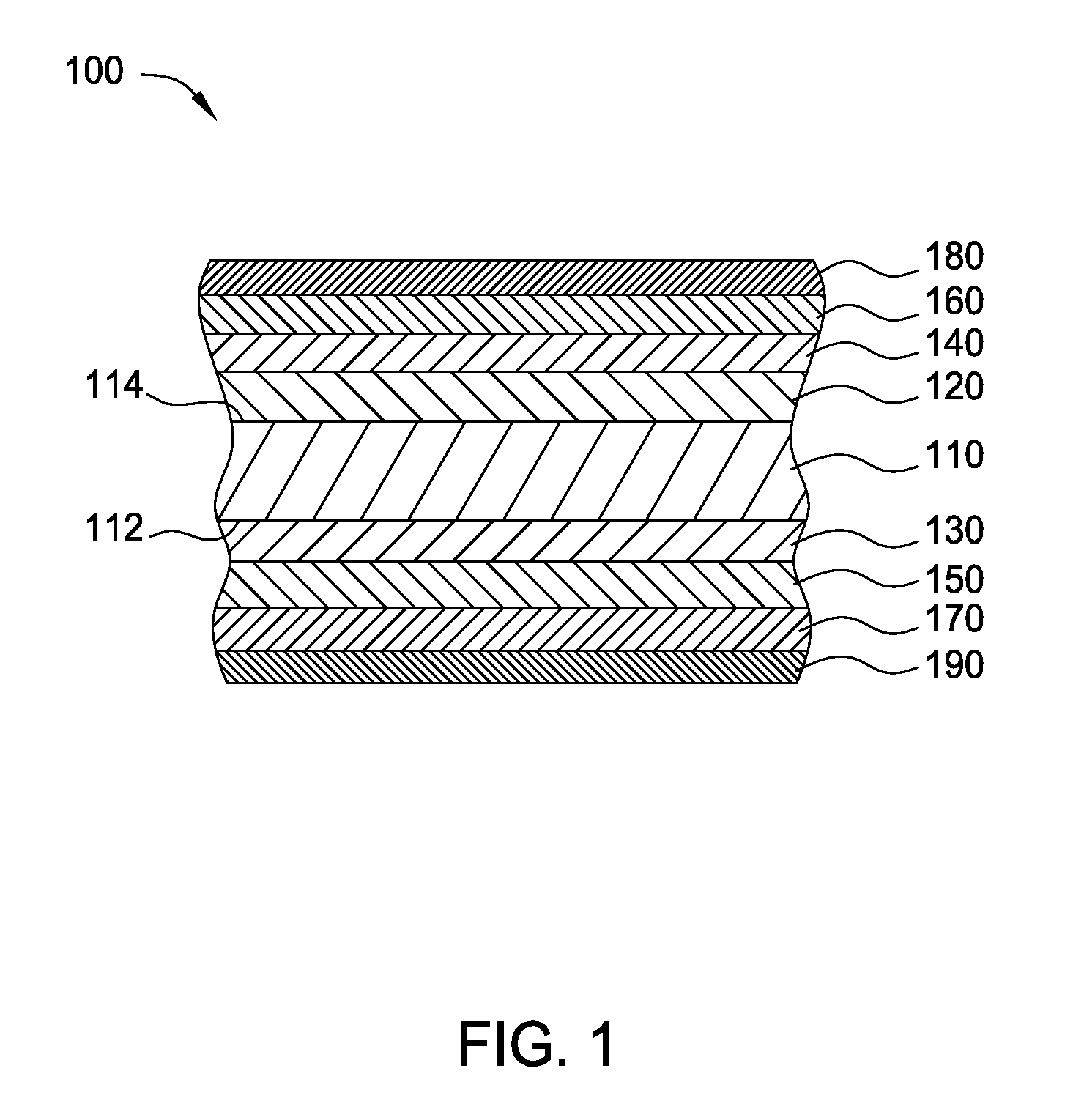

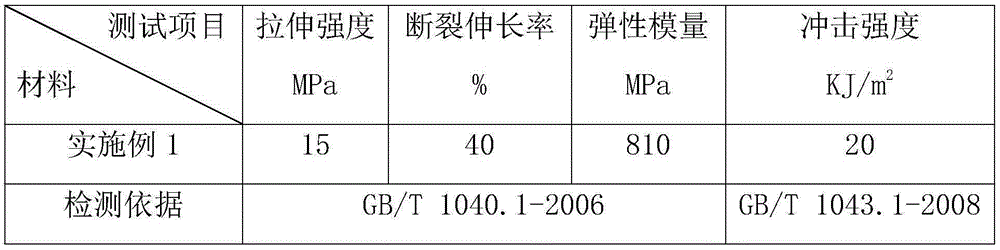

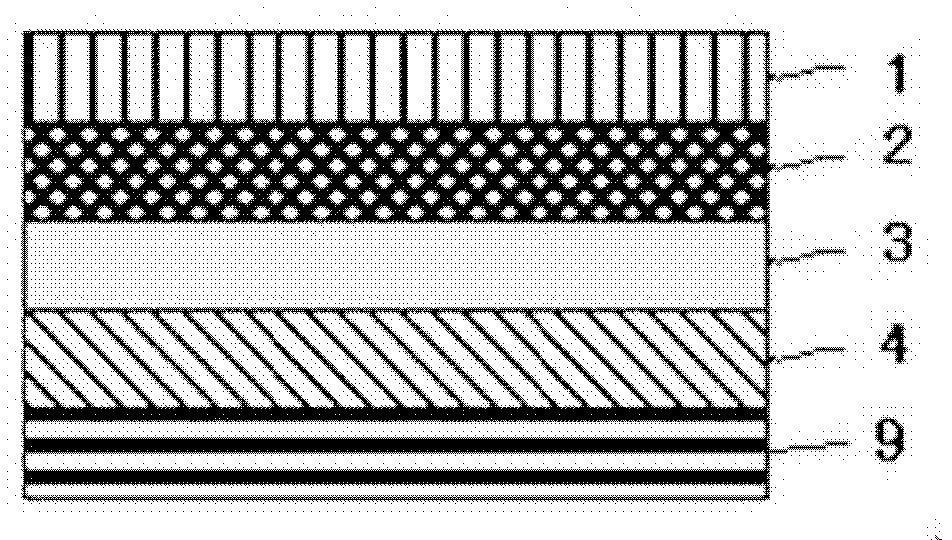

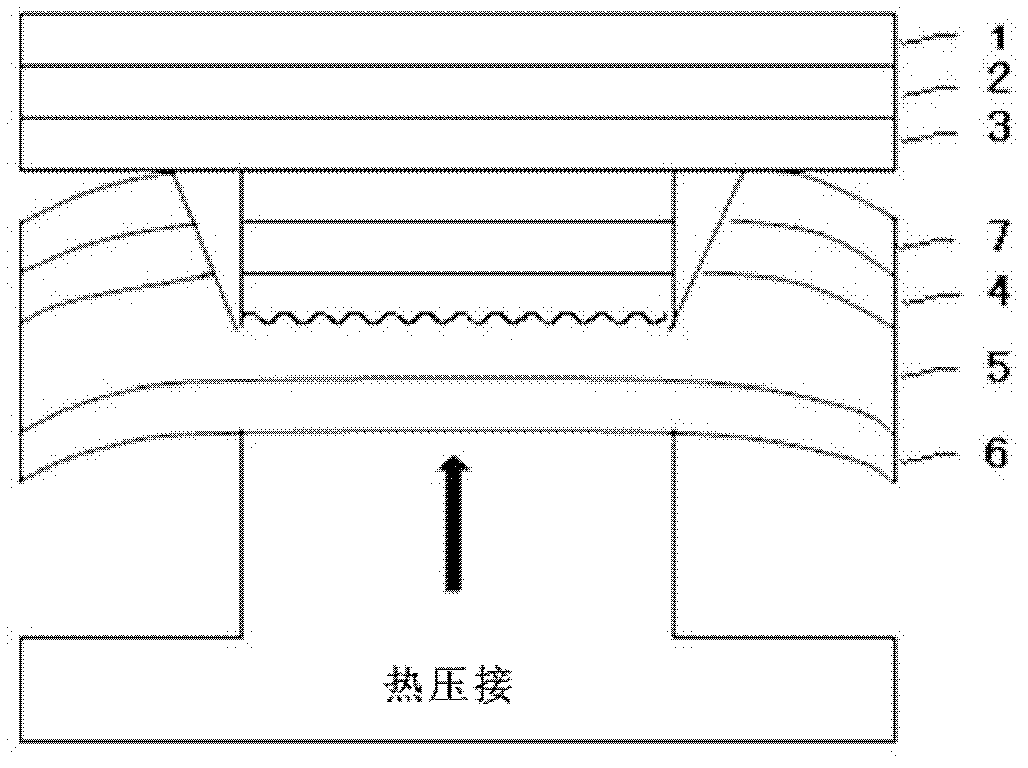

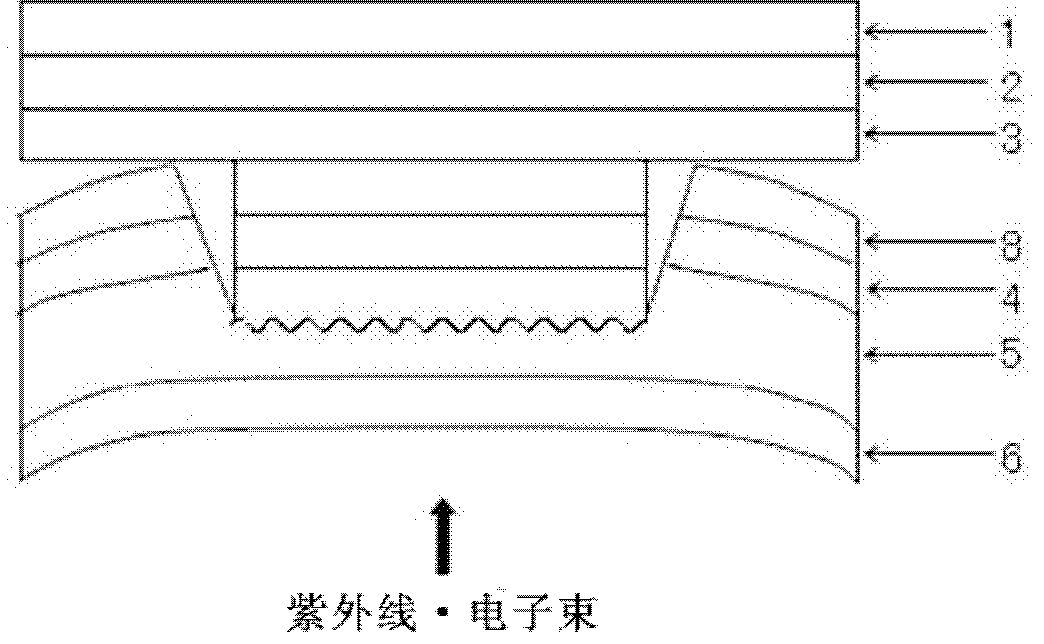

Laminated paper base plate used in drilling of PCB (Printed Circuit Board) and manufacturing method of laminated paper base plate

ActiveCN103950247AImprove flatnessAvoid deformationPaper/cardboardInorganic compound additionCooking & bakingPrinted circuit board

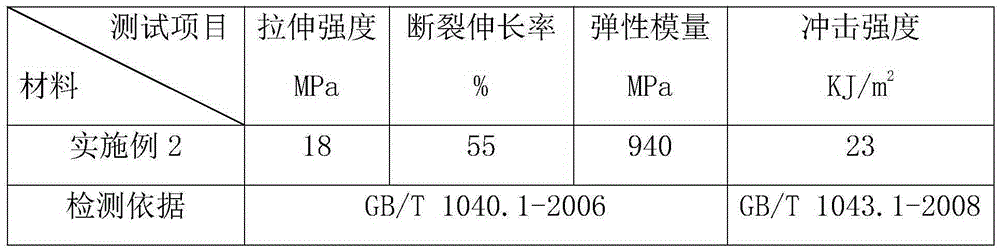

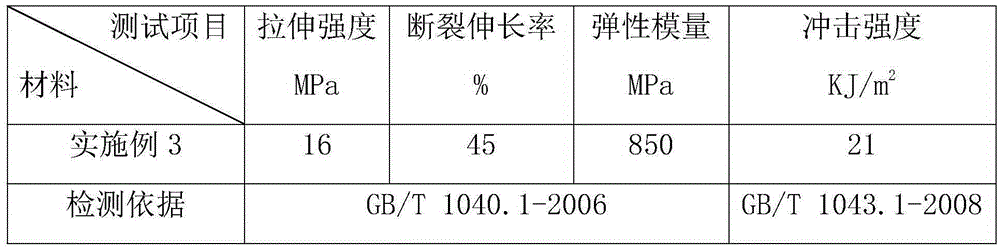

The invention discloses a laminated paper base plate for use in drilling of a PCB (Printed Circuit Board) and a manufacturing method of the laminated paper base plate. The base plate comprises an inner layer consisting of inner paper, and surface paper arranged on the upper and lower surfaces of the inner layer, wherein the inner paper is obtained by steeping kraft paper with modified urea formaldehyde resin, baking and cutting; the formula of the modified urea formaldehyde resin comprises the following components in parts by weight: 100 parts of urea formaldehyde resin, 20-50 parts of a toughening modifier, 2-6 parts of filler, 0.5-1 part of a dispersing agent and 20-40 parts of a viscosity adjusting agent; the surface paper is obtained by steeping balance paper or wood pulp paper with the urea formaldehyde resin, baking and cutting. The base plate is manufactured by adopting a specific process, so that wear to a drill pin during drilling is reduced; burrs are reduced, the hole wall quality of drilled holes is improved, and the problem of warping of the urea formaldehyde resin is solved. The base plate has the advantages of high flatness, no deformation, high weather resistance and proper strength, is relatively low in production cost, and has a wide application prospect and the high market competitiveness.

Owner:SHENZHEN NEWCCESS IND

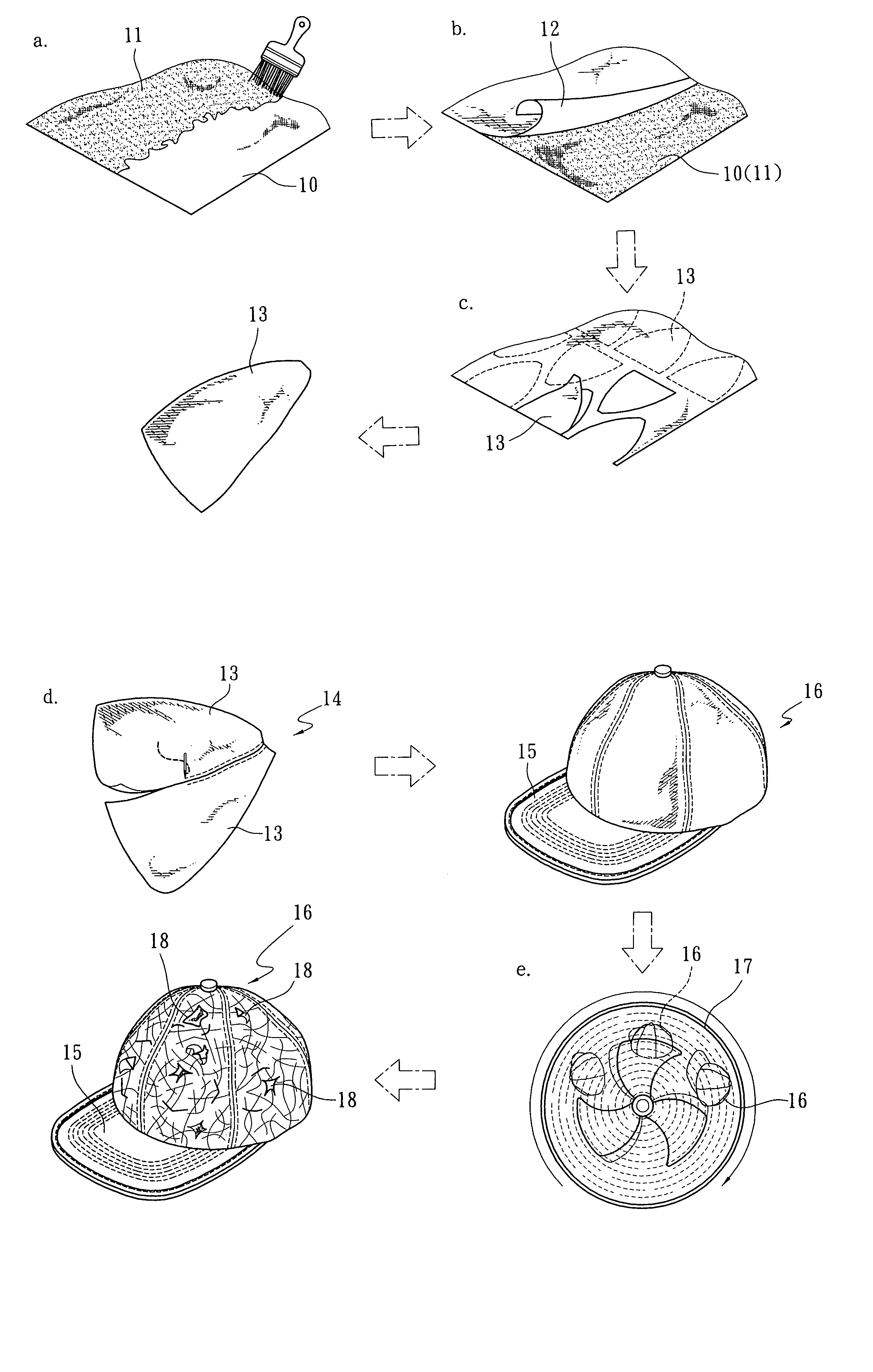

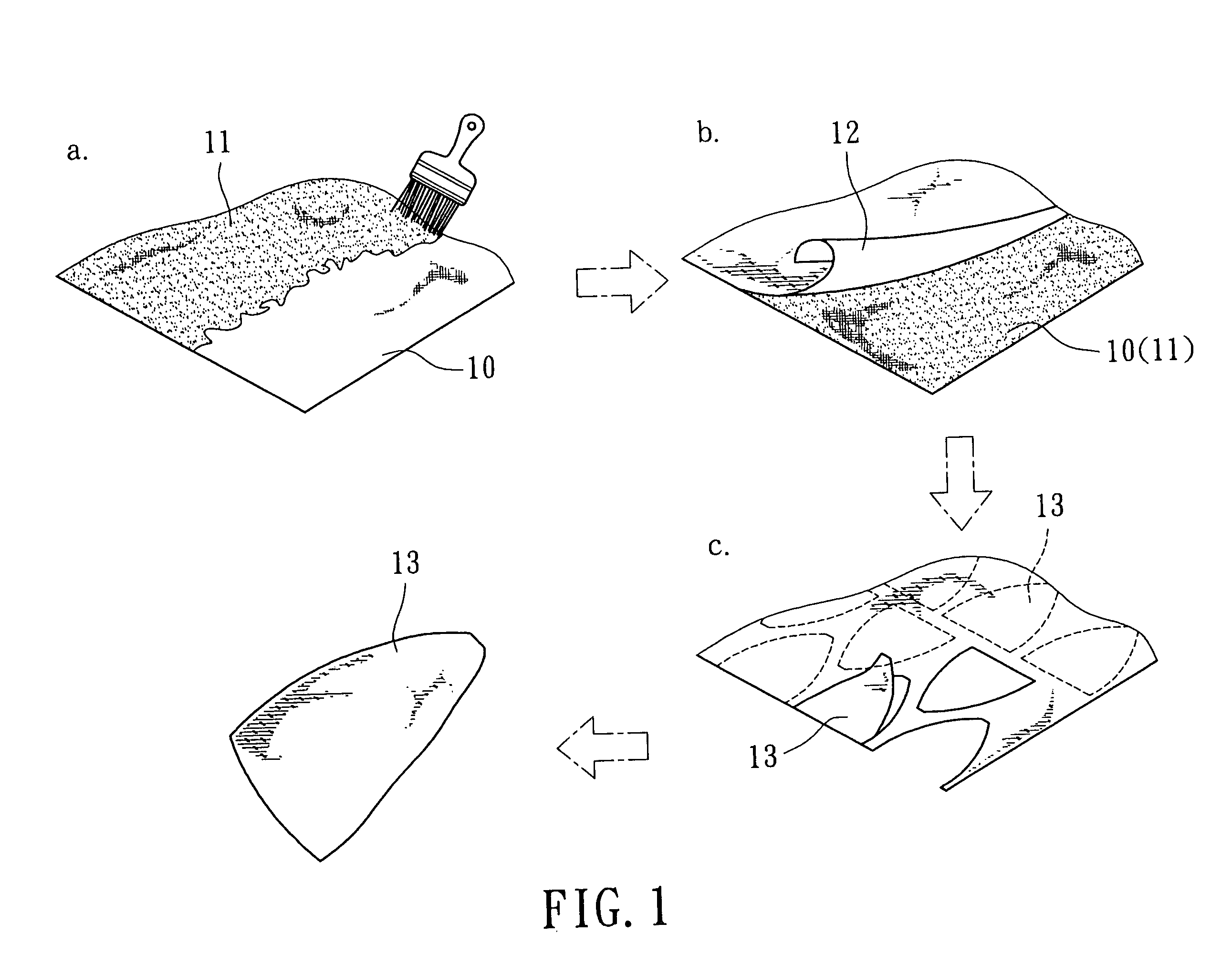

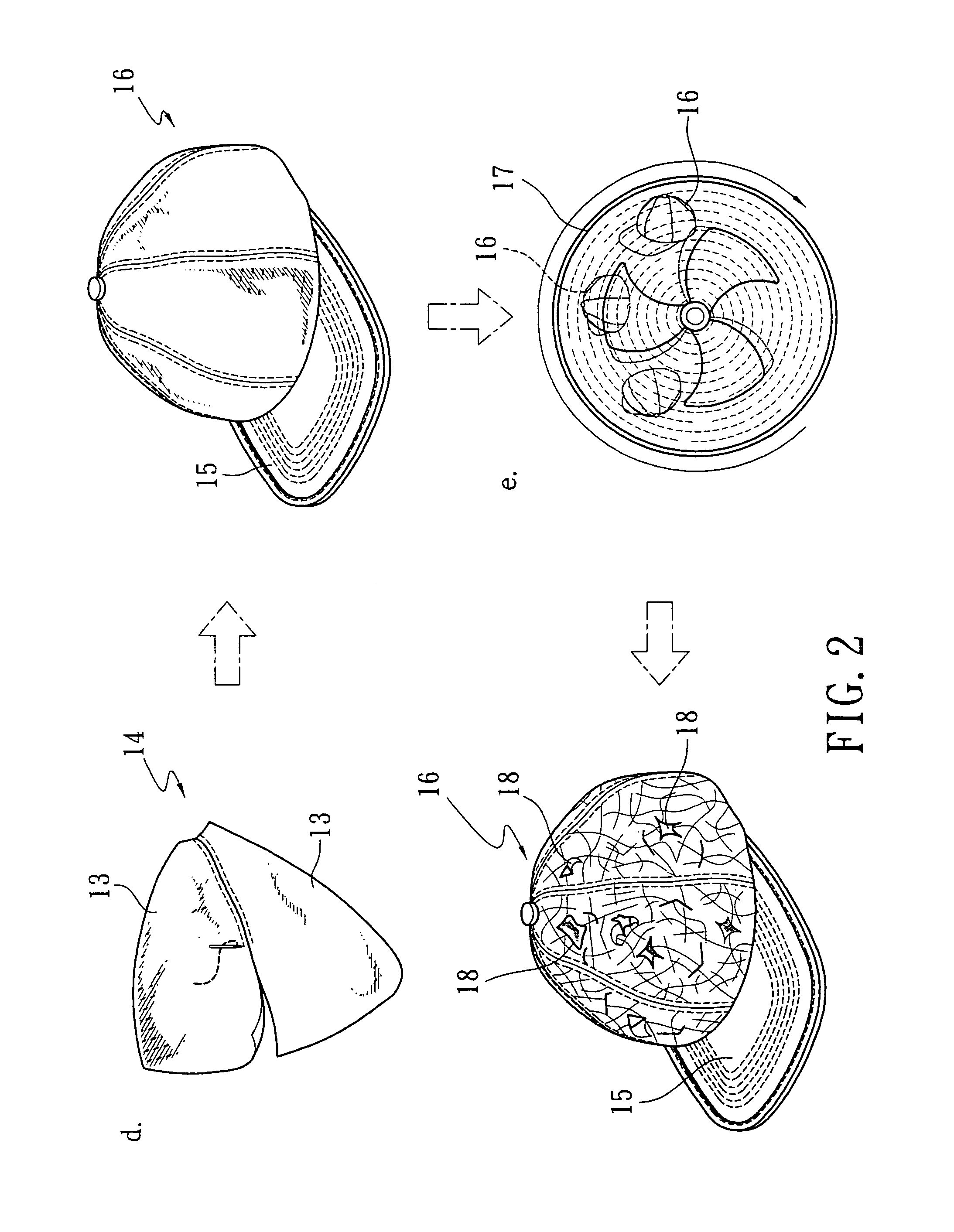

Method for manufacturing headgear of a peeling off effect

InactiveUS7000553B1Keep freshnessChange appearanceHand sewingHatsPulp and paper industryLamination paper

A method of manufacturing headgear of a peeling off effect adopts papers in the headgear manufacture, i.e. pluralities of laminated papers are combined with a fabric, and then integrally colored, cut and sewn to form a headgear. After a wash treatment, the paper material of the headgear will gradually peel off to engender a cracked effect of different degrees on the appearance depending the length of the use time, thereby obtaining an ancient, pioneering and special style.

Owner:WANG TAI KUANG

Polyolefin and cellulose laminate for food and beverage containers

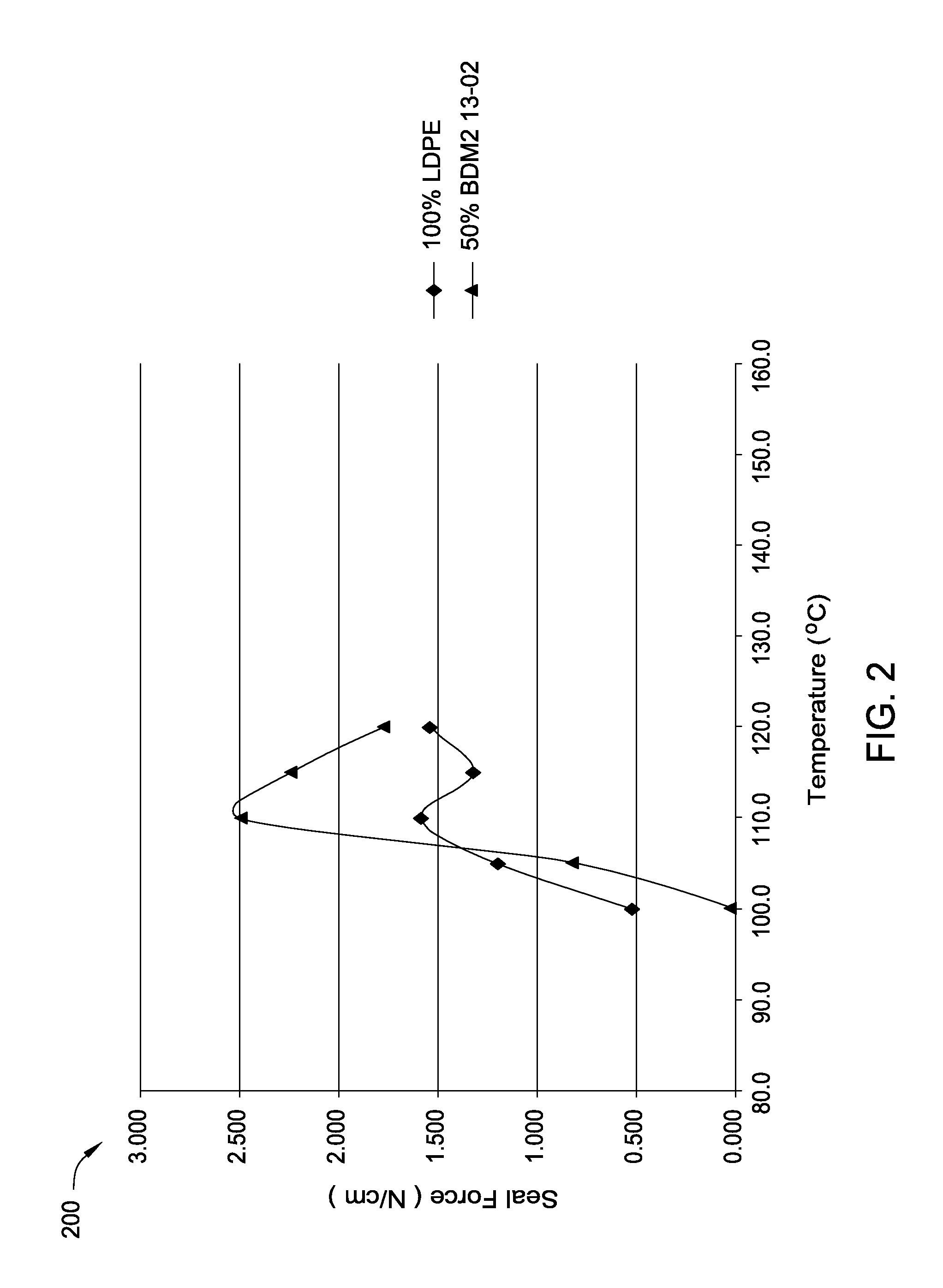

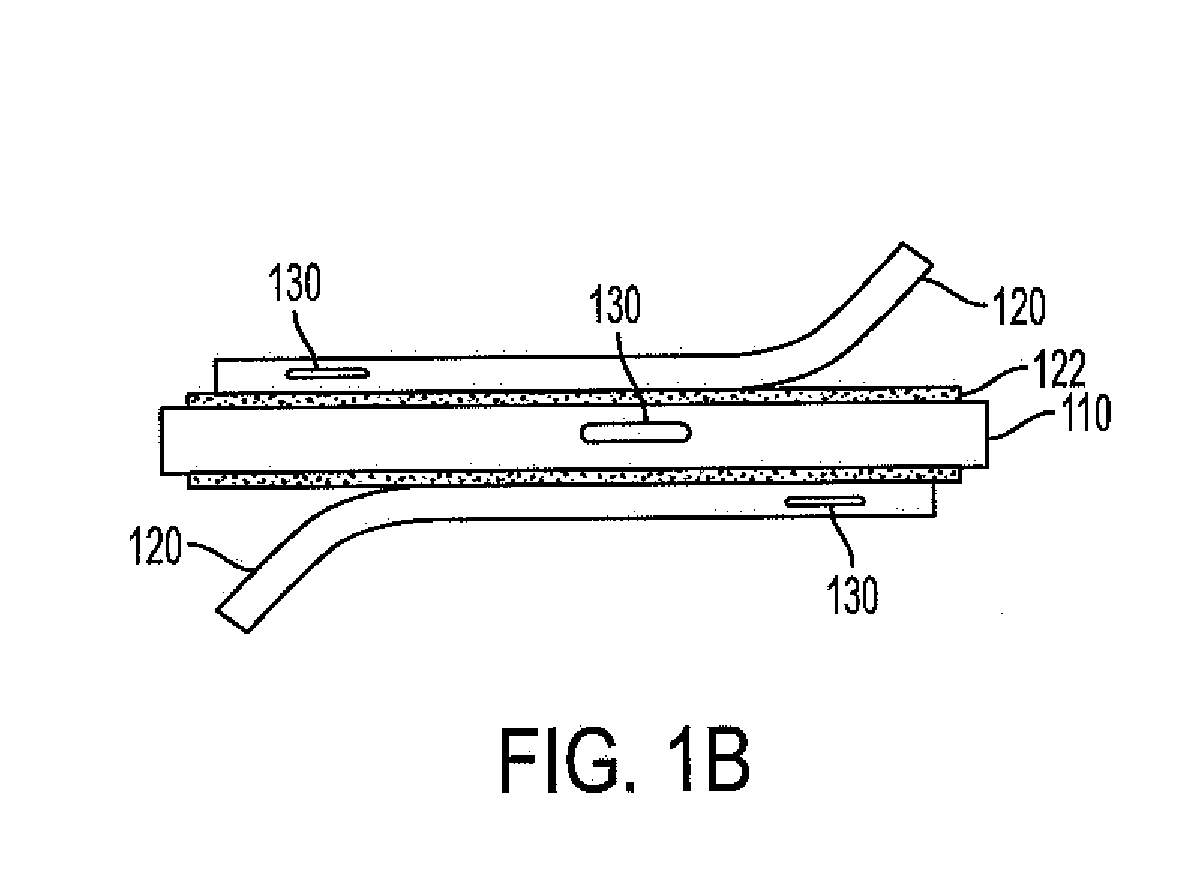

InactiveUS20140367456A1Improve seal strengthEliminate the problemLiquid surface applicatorsPaper/cardboardLow-density polyethylenePolyvinyl polymer

A method and apparatus for in one implementation, a rigid paperboard container, the container being constructed from extrusion coated or laminated paperboard is provided. The rigid paperboard container comprises (a) a paperboard substrate having opposed inner and outer surfaces, (b) a first polymer layer coated or laminated onto the outer surface of the paperboard substrate, the first polymer layer comprising (i) metallocene catalyzed polyethylene polymer and (ii) optionally LDPE, (c) a second polymer layer coated or laminated over the first polymer layer, the second polymer layer comprising (i) metallocene catalyzed polyethylene polymer and (ii) LDPE and (d) a third polymer layer coated or laminated over the second polymer layer, the third polymer layer comprising (i) metallocene catalyzed polyethylene polymer and (ii) optionally low density polyethylene polymer (LDPE).

Owner:KOLM POLYMERS

Treated inorganic pigments having improved dispersability and use thereof in paper products

The disclosure provides a laminate paper comprising a treated inorganic core particle, in particular treated titanium dioxide (TiO2) particle, having improved dispersability, prepared by a process comprising: (a) heating a slurry comprising porous silica treated inorganic core particle and water at a temperature of at least about 90° C.; and (b) adding a soluble alumina source to the slurry from step (a) while maintaining the pH at about 8.0 to 9.5 to form an alumina treatment on the porous silica treated inorganic core particle; wherein the treated inorganic core particle does not comprise dense silica or alumina treatments, and has silica present in the amount of about 7% to about 14% and alumina present in the amount of about 4.0% to about 8.0%; and wherein the particle to particle surface treatments are substantially homogeneous.

Owner:THE CHEMOURS CO FC LLC

Laminated paper for xerography to reduce cost and recycling waste

InactiveUS20110155311A1Lamination ancillary operationsSynthetic resin layered productsSurface layerXerography

An imageable medium includes a reusable substrate and a removable surface layer semi-permanently bonded to a major surface of the substrate, the reusable substrate comprising an opaque backing to the removable surface layer and the removable surface layer comprising an imageable surface. A use indicator can be incorporated into the imageable medium, and correspond to at least one of the reusable substrate and removable surface layer. The use indicator can be an RFID chip. A method of imaging includes preparing an imageable medium by semi-permanently bonding an imageable layer to a reusable substrate, the reusable substrate providing an opaque backing to the imageable layer; imaging the imageable layer of the imageable medium; removing an imaged layer upon completion of use of the imaged medium; and repeatedly imaging a revealed imageable layer and removing the imaged layer.

Owner:PALO ALTO RES CENT INC

Dispersions made from treated inorganic particles for making decor paper having improved optical performance

The disclosure provides a dispersion for making décor paper having improved optical performance without negatively impacting mechanical strength comprising a TiO2 particle slurry comprising a treated TiO2 particle having a surface area of at least about 30 m2 / g, and a cationic polymer; wherein the treatment comprises an oxide of silicon, aluminum, phosphorus or mixtures thereof; and the treatment is present in the amount of at least 15% based on the total weight of the treated titanium dioxide particle; paper pulp; and a cationic polymer; wherein the cationic 1.5 polymer in the slurry and the cationic polymer in the dispersion are compatible; wherein for equal optical performance, the amount of treated TiO2 particle in the dispersion is reduced by about 10% when compared to a dispersion not comprising the treated TiO2 particle of (a). These dispersions are useful in making décor paper that may be used in paper laminates.

Owner:THE CHEMOURS CO FC LLC

Preparation method of high-retention decorative-laminated-paper titanium oxide powder

InactiveCN107254197AHigh glossImprove retentionInorganic pigment treatmentPhosphoric acidALUMINUM PHOSPHATE

The invention discloses a preparation method of titanium dioxide for decorative laminated paper with high retention rate, and belongs to the technical field of titanium dioxide production. The invention firstly uses aluminum sulfate octadecahydrate as a raw material, controls the precipitation morphology through ammonia water, and obtains nano-flaky alumina, which is modified by tin tetrachloride, a silane coupling agent and the like and used as a template, and then titanium tetrachloride is used as a template. As a titanium source, the nano-sheet alumina is coated, and then the aluminum phosphate layer and the alumina layer are sequentially coated to obtain a mixed solution of re-coated titanium dioxide. The titanium dioxide for decorative laminated paper with high retention rate can be obtained by grinding. The titanium dioxide prepared by the invention can improve the light resistance, dispersibility and hiding power of the titanium dioxide in the laminated paper very well, and can meet the requirements of titanium dioxide for laminated paper. requirements.

Owner:朱文杰

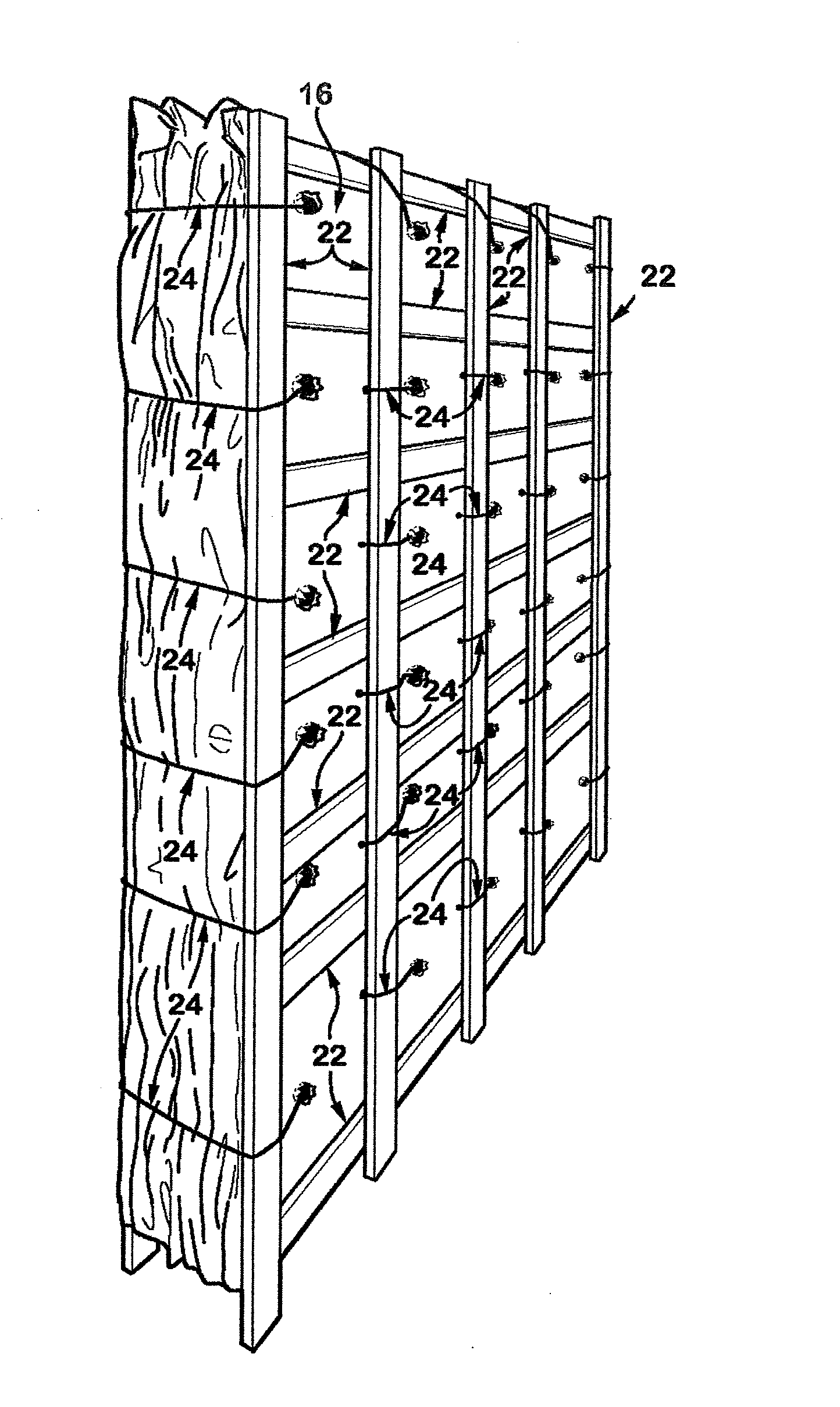

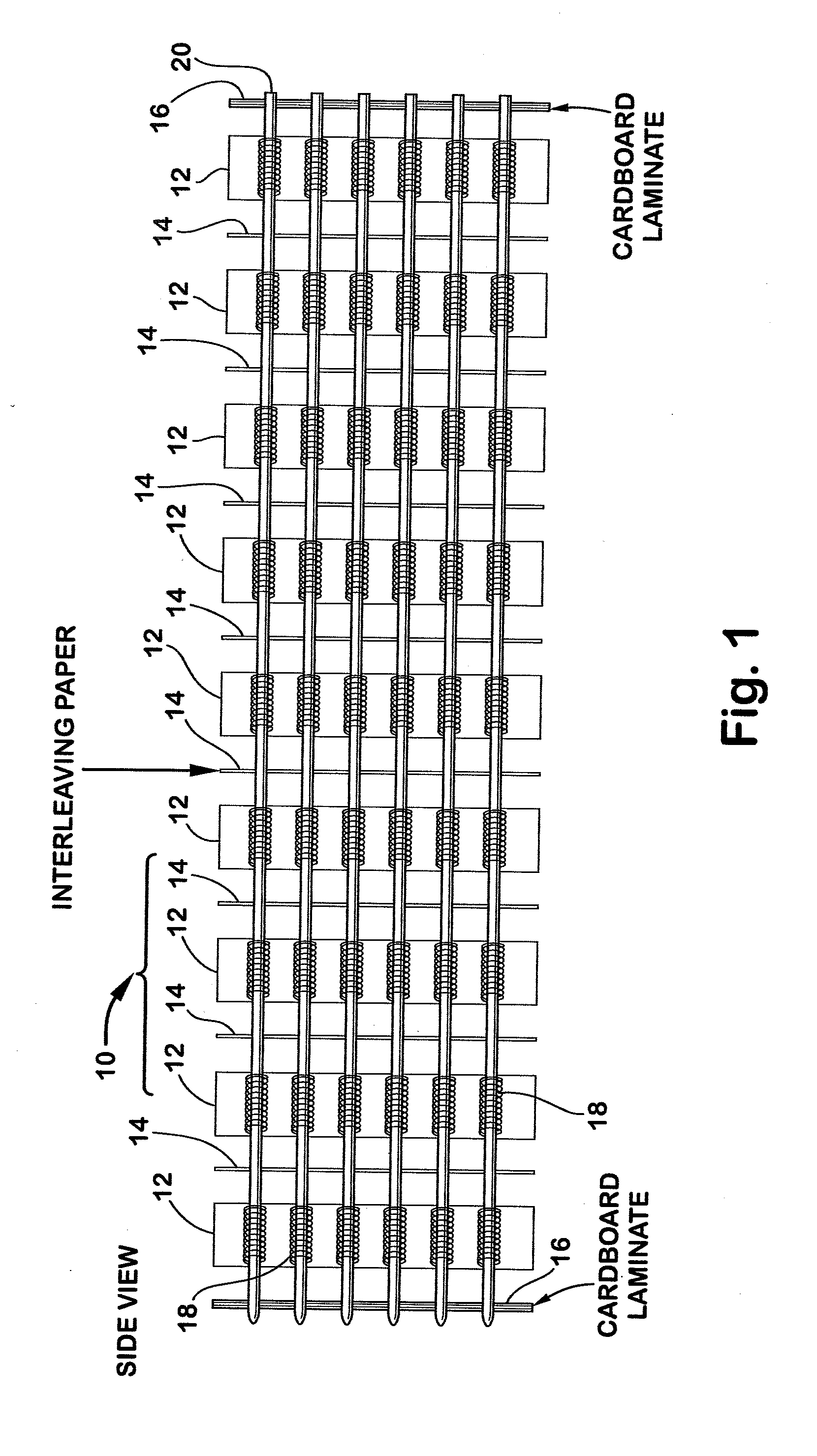

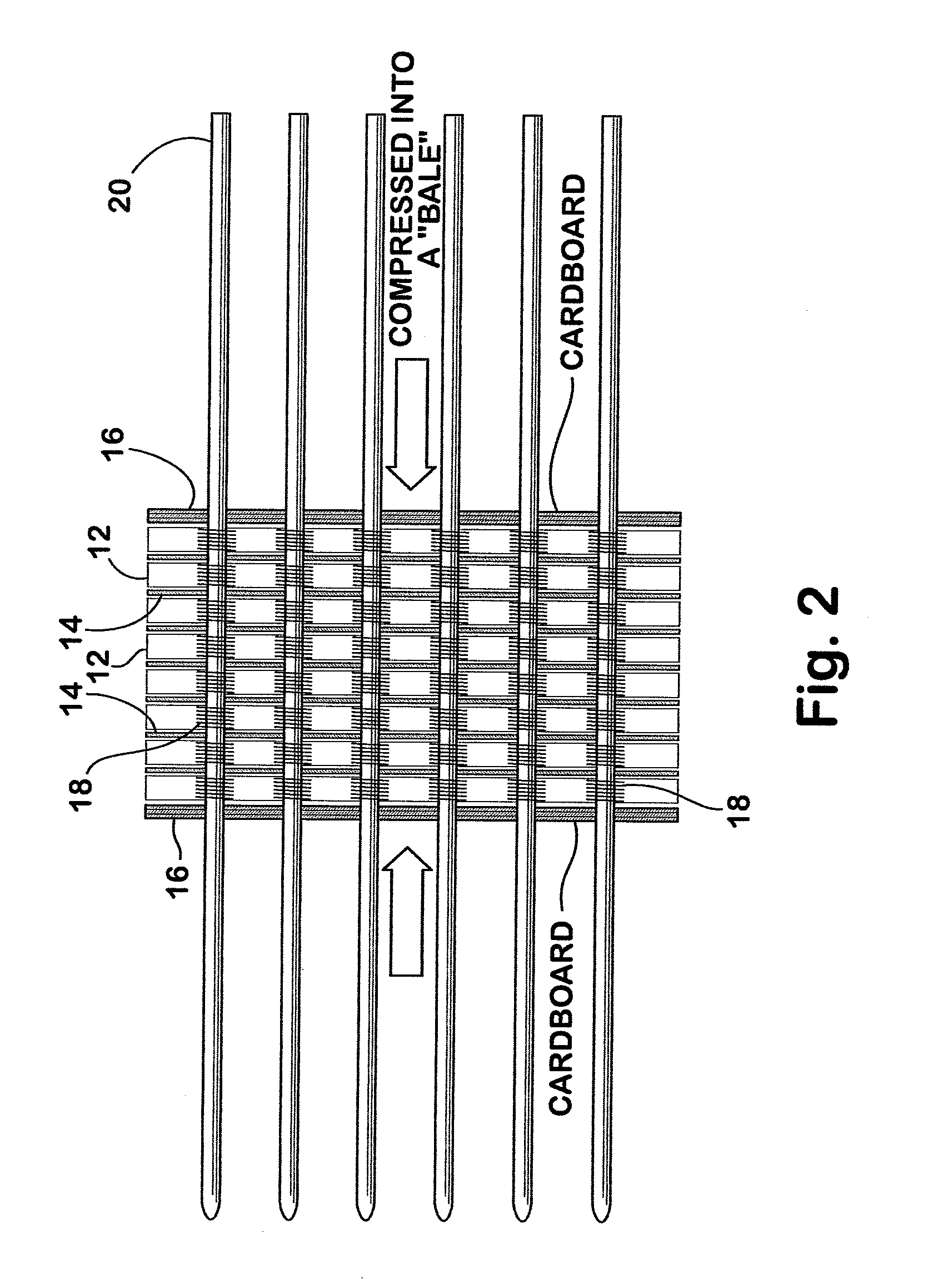

Box spring packaging method and apparatus

InactiveUS20160318680A1No additional benefitContainers for flexible articlesSpring mattressesEngineeringWater soluble

Improved packaging materials for packaging multiple mattress spring cores together in a compressed stack, wherein the two ends of the stack are covered by end panels comprising a laminated paper stack panel that includes one or more layers of a stretchable paper called extensible kraft paper laminated together with a water soluble glue. The mattress spring cores are separated by an interleaving sheet comprising one layer of extensible kraft paper.

Owner:WOLVERINE AUTOMOTIVE BOARD SALES INC

Biomass lamination material for lamination paper and preparation method thereof

The invention particularly provides a biomass lamination material for lamination paper. The biomass lamination material for the lamination paper is prepared from, by mass, 75%-95% of full-biomass polyethylene, 2%-5% of lubricating agents and 3%-20% of fillers, wherein the full-biomass polyethylene is formed by polymerizing ethylene, and the ethylene is prepared from ethyl alcohol obtained through fermentation of starch or cellulose or lignin through dehydration. According to the biomass lamination material for the lamination paper, the main raw materials are taken from natural renewable substances, the whole materials are disintegrated into debris along with biodegradation of the renewable substances, a certain degradation property is achieved, and a positive effect on reduction in carbon dioxide emission is achieved.

Owner:WUHAN HUALI BIOLOGY CO LTD

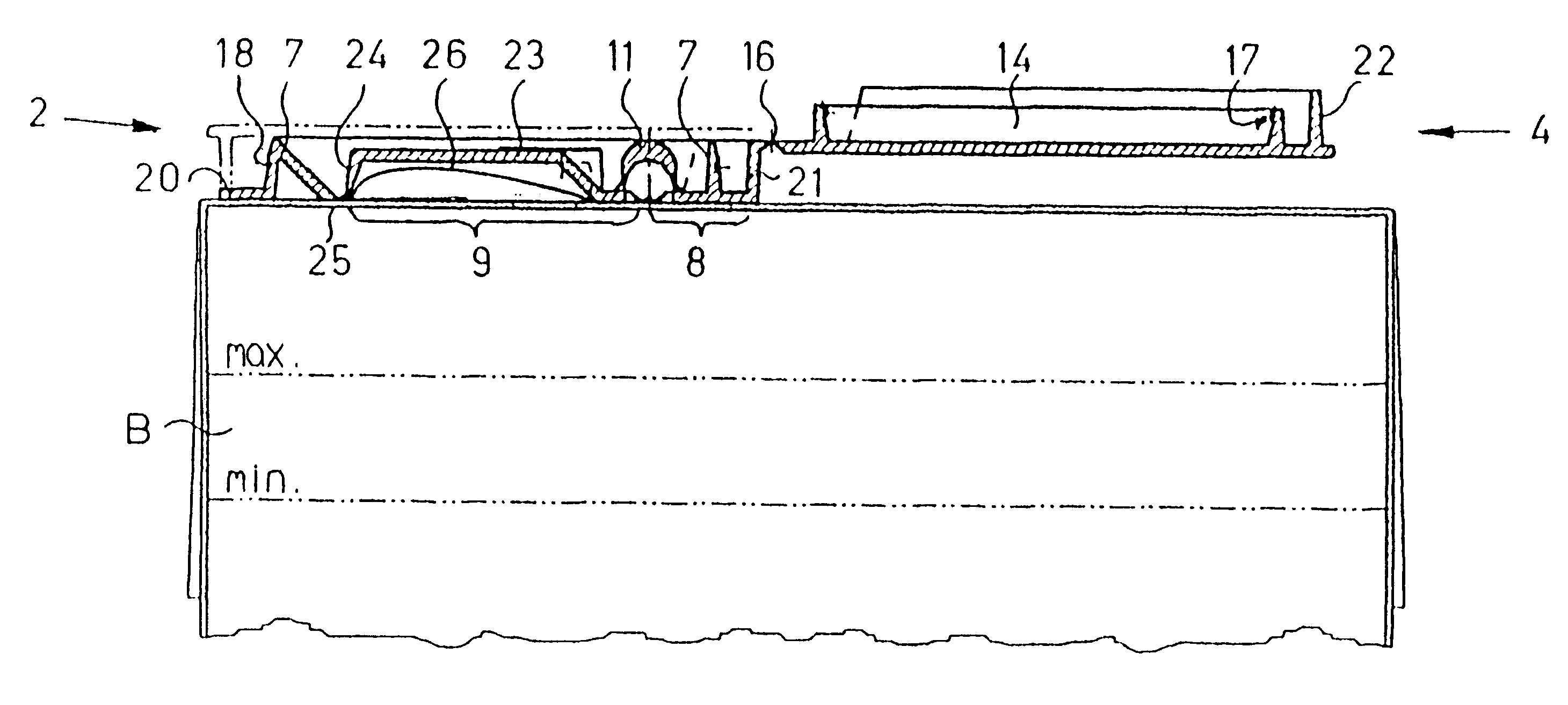

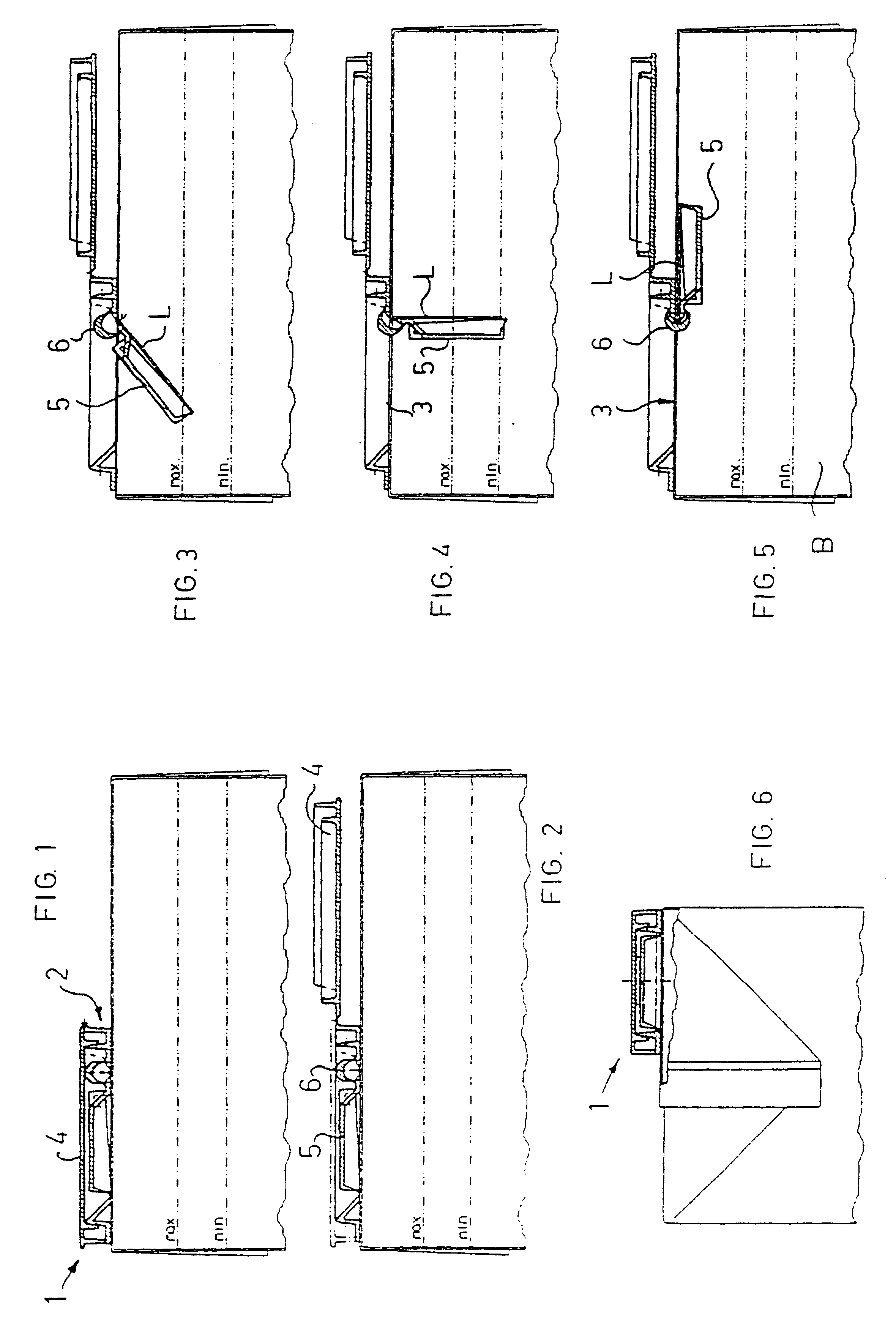

Improved industrial container for packaging and transporting multiple glass panels or the like

ActiveCN105392716AEasy to storeReduce occupancyShock-sensitive articlesDamagable goods packagingFlat glassEngineering

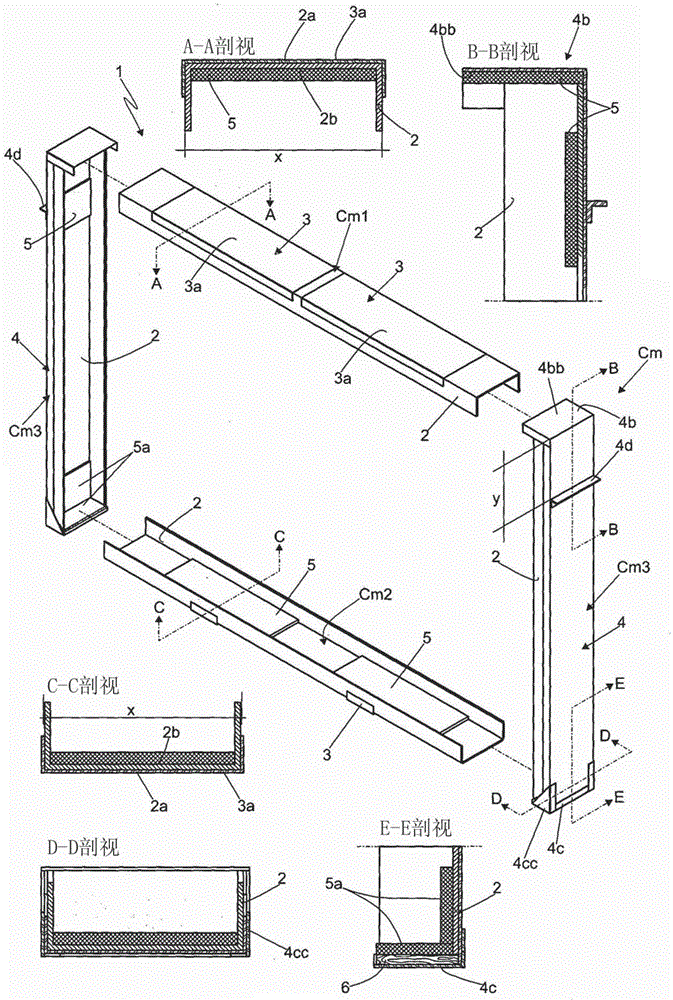

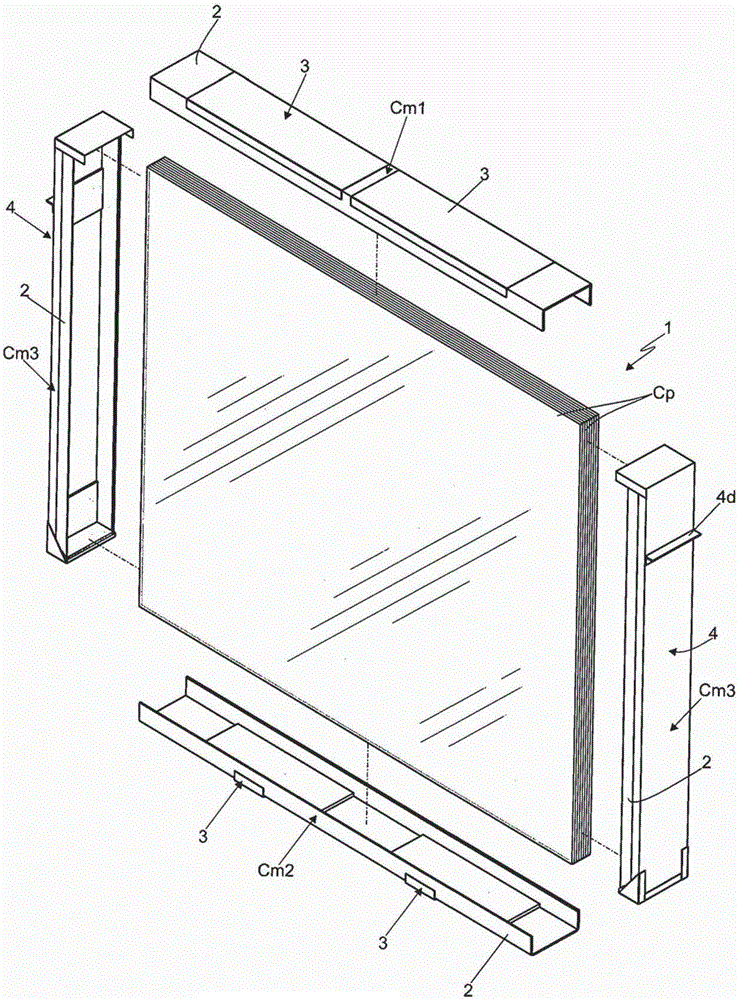

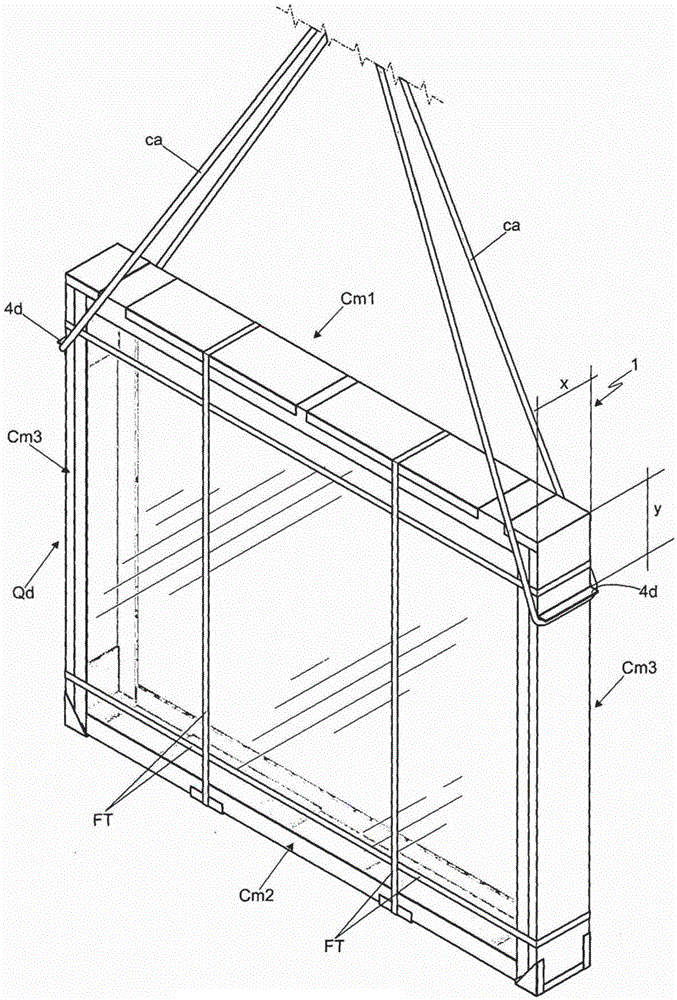

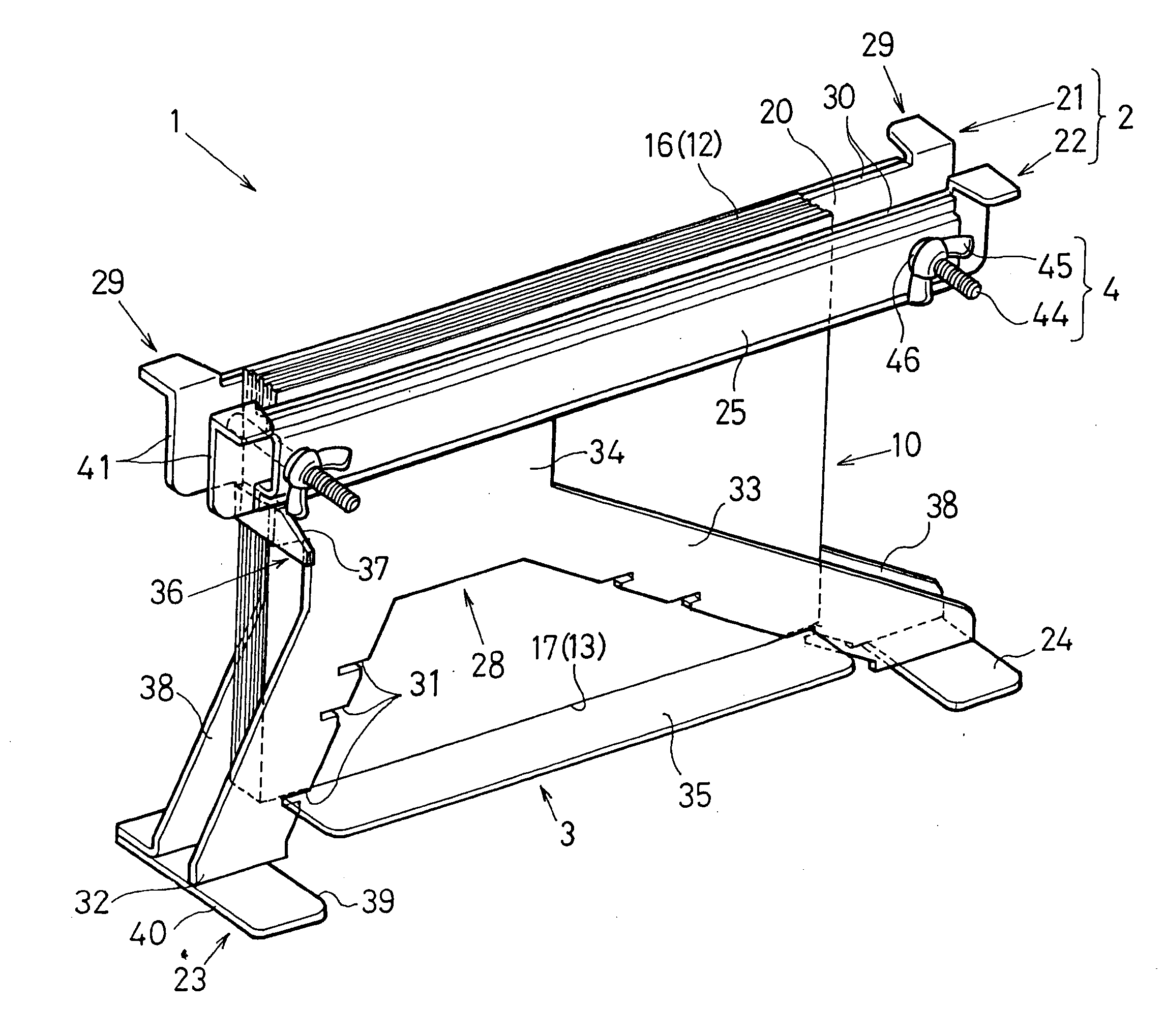

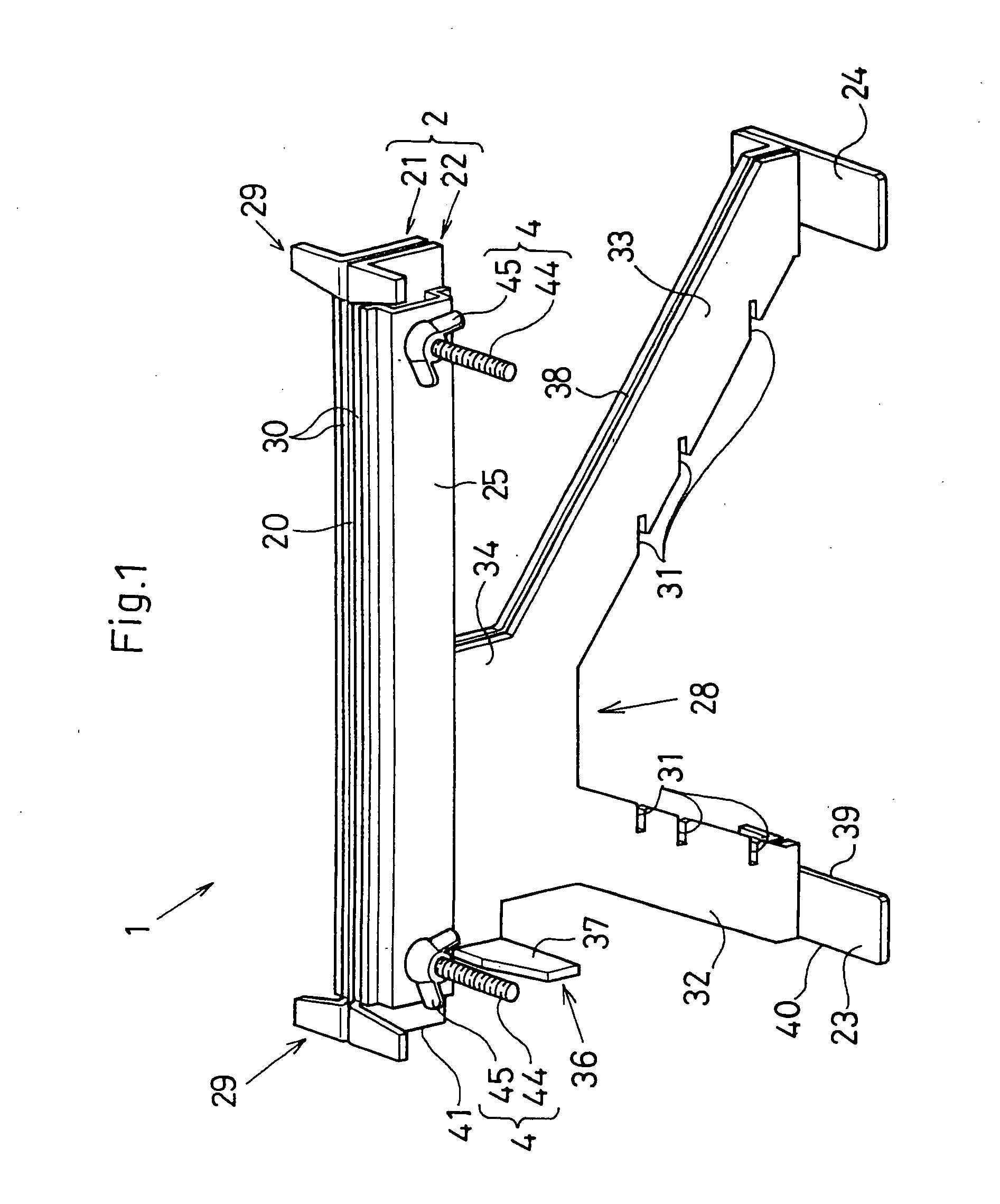

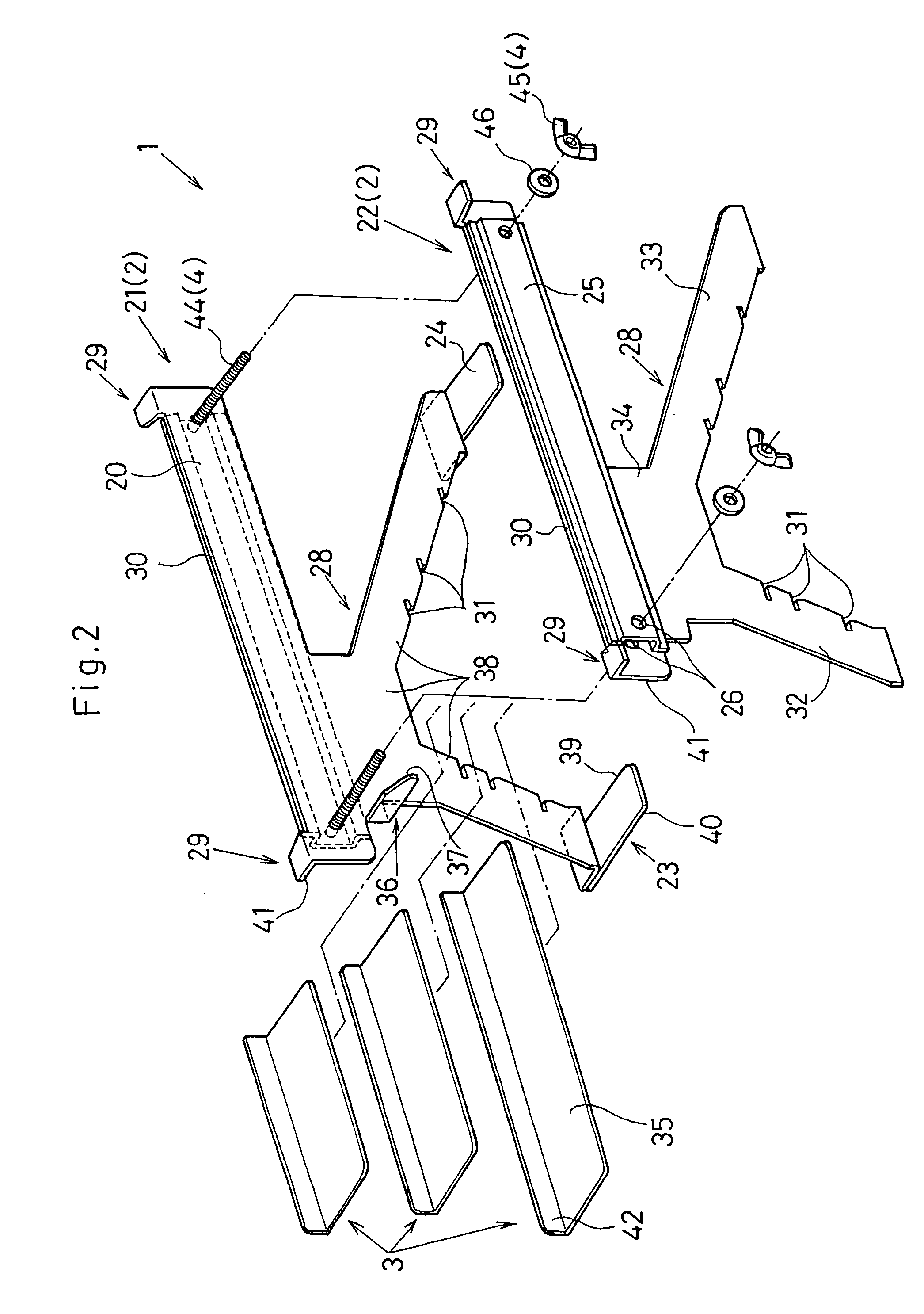

The invention relates to an industrial container (1) to be used as an envelope to protect the perimeter of the block formed by multiple panels (Cp) packaged into the container (1), for example flat glass panels or panels of other materials to be transported in the vertical position; the container comprises a framework (Qd) formed by a set of modular troughs (Cm), including an upper trough (Cm1), a lower trough (Cm2) and a pair of identical side troughs (Cm3), which are essentially composed of longitudinal profiles (2) with a U-shaped cross-section and a narrow width (x) for receiving a multiple panels (Cp); these profiles (2) are made of laminated paper or another suitable material, the profiles (2) of the upper trough (Cm1) and lower trough (Cm2) comprising reinforcement zones (3) for binding by means of strips (FT), the reinforcement zones (3) being formed by the juxtaposition of pairs of steel plates (3a) on the flat surface (2a) of the longitudinal profiles (2), while the longitudinal profiles (2) of each side trough (Cm2) also receive a protection cover (4) that has a U-shaped cross-section and is made of steel; the flat inside surface (2b) of the profiles (2) of the modular troughs (Cm) receives internal supports (5) for accommodating and protecting the peripheral edges of the multiple panels (Cp) packaged inside the framework (Qd).

Owner:塞萨·瓦伦蒂姆·赞奇特

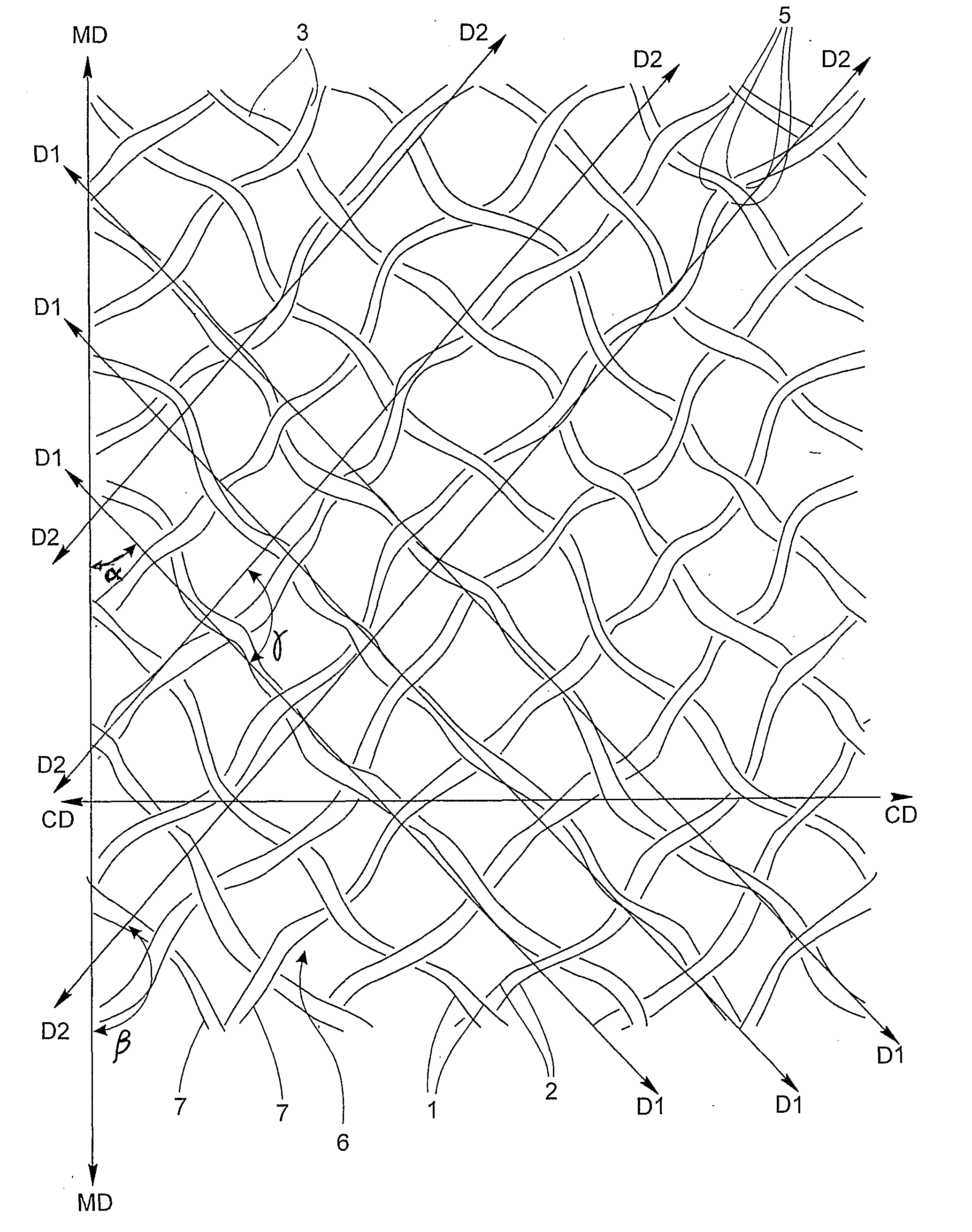

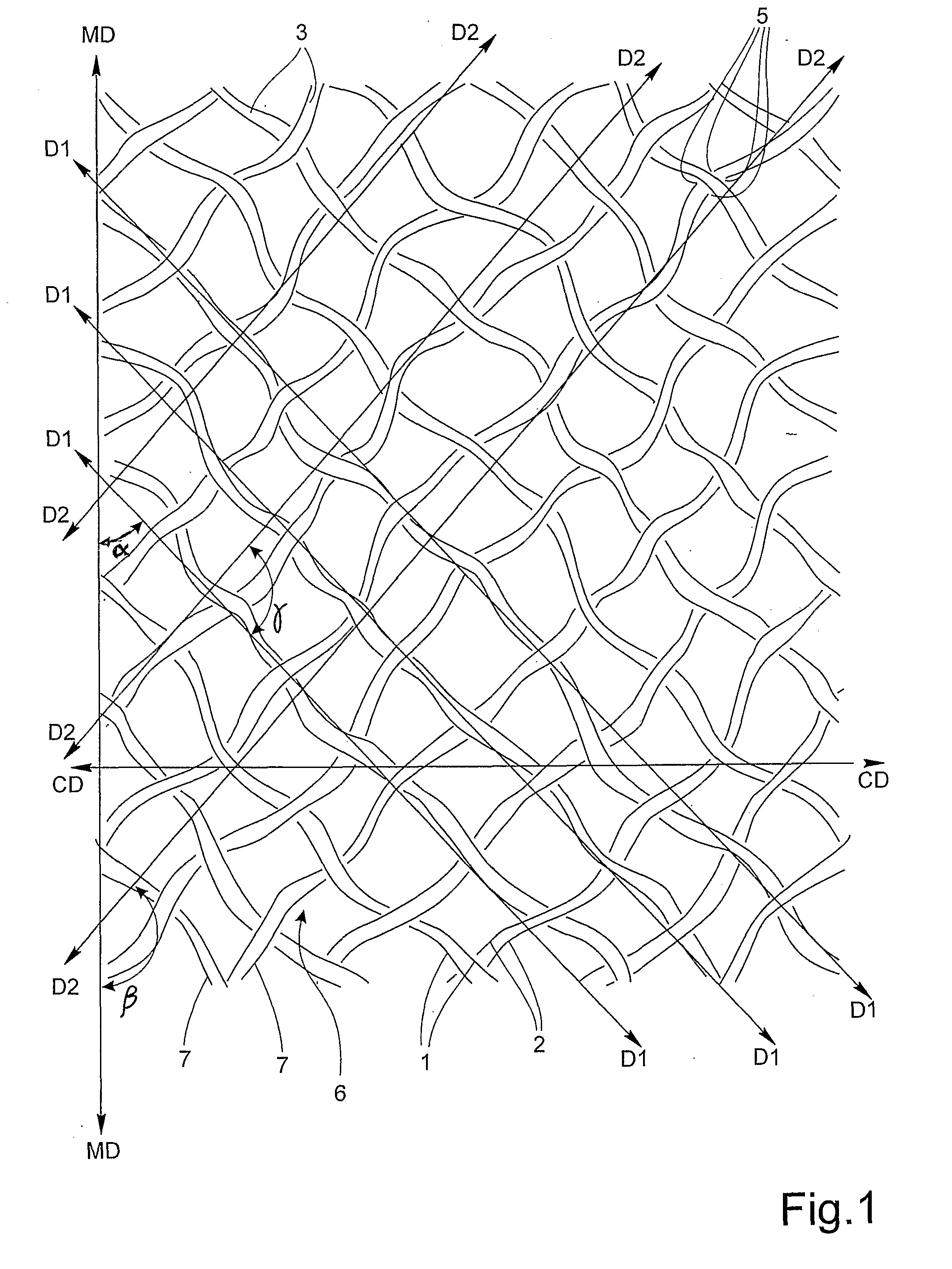

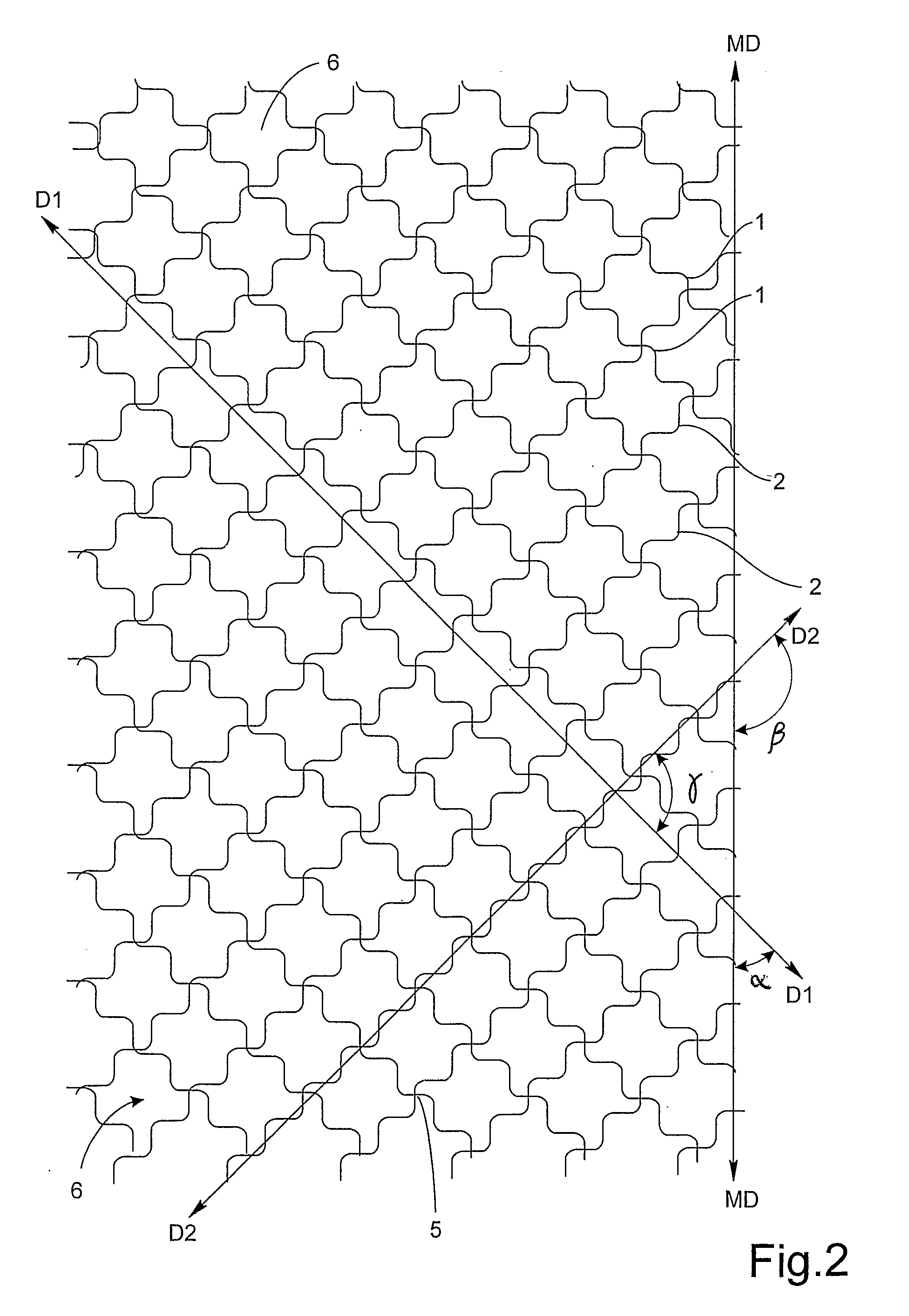

Laminated paper article and paper web

Owner:ESSITY HYGIENE & HEALTH AB

Paper cup comprising a sheet of polylactic acid laminated paper

InactiveUS20080176015A1Facilitates adoptionReduce environmental pollutionFlexible coversWrappersCardboardAdhesive

A biodegradable paper cup comprising a single PLA laminated paper sheet can be manufactured using no adhesives. Employing a single PLA laminated paper sheet in which barium sulfate or precipitated barium sulfate is compounded with a PLA resin as cup making materials.

Owner:YAMAMATSU TAKEYUKI

Polyester resin and laminate paper using the same

InactiveUS20060134444A1Improve barrier propertiesIncrease thermal resistanceSynthetic resin layered productsPaper/cardboard layered productsHeat resistancePolyester resin

A polyester laminate paper with excellent adhesiveness, thermal resistance, moldability and the like as prepared by laminating a polyester resin in a pellet form on at least one of the faces of a paper, the polyester resin containing a butylene terephthalate recurring unit as the main component and satisfying the following conditions (1) and (2): (1) the melt tension thereof at 250° C. is 0.5 to 2.5 mN; and (2) the difference (ΔIV) between the intrinsic viscosity of pellet surface part IV (S) and the intrinsic viscosity of pellet center part IV (C) is 0.1 or less.

Owner:MITSUBISHI ENG PLASTICS CORP

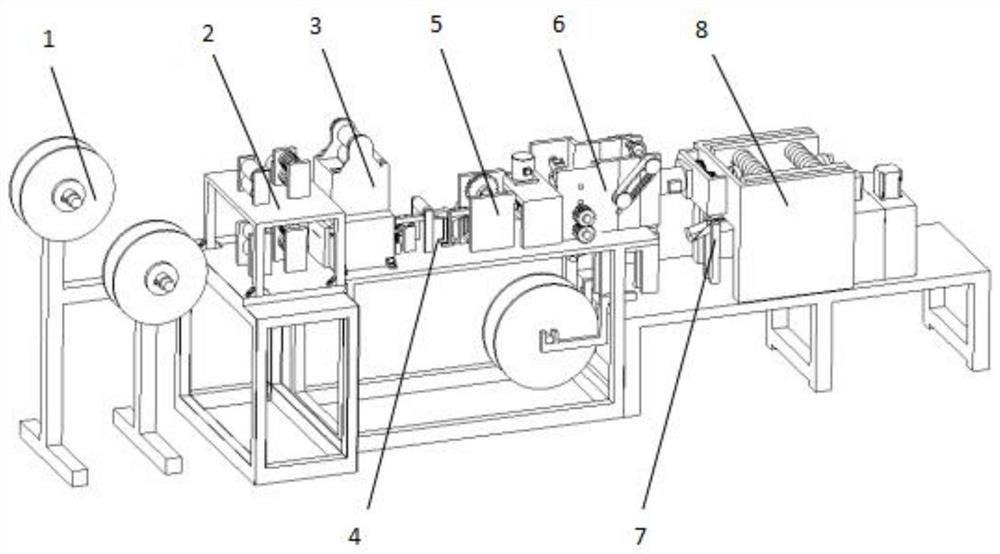

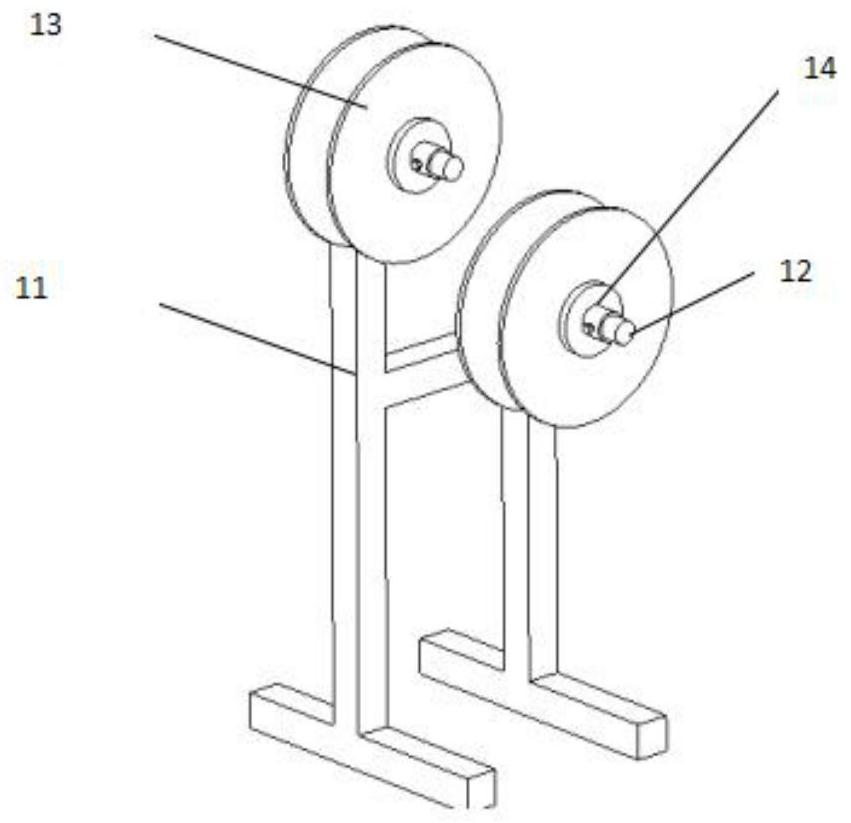

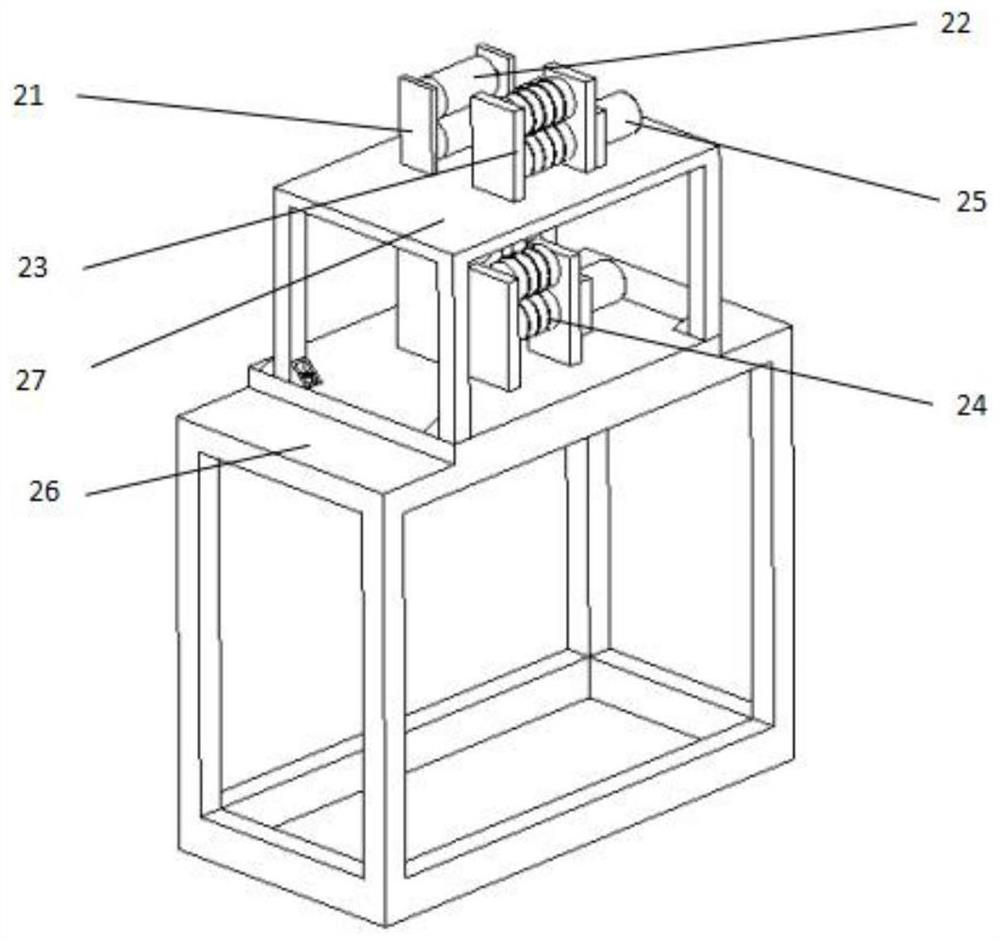

Compressible automatic paper straw processing and forming device and working method

ActiveCN112277390AImprove adhesionHigh degree of automationPaper/cardboard articlesWrapper twisting/gatheringMechanical engineeringLamination paper

The invention discloses a compressible automatic paper straw processing and forming device and a working method. The compressible automatic paper straw processing and forming device comprises a feeding device, an inner and outer layer paper pressing device, a gluing device, an inner and outer layer paper forming device, a press-fitting device, a shearing device, a film packaging device and a heatsealing device; the feeding device is fixedly installed on the ground through foundation bolts; the inner and outer layer paper pressing device is installed behind the feeding device; the gluing device is installed above the inner and outer layer paper forming device through bolts; the inner and outer layer paper forming device is installed behind the inner and outer layer paper pressing device; the press-fitting device is fixedly installed behind the inner and outer layer paper forming device through bolts; the shearing device is fixedly installed on the inner and outer layer paper forming device through bolts and is located behind the press-fitting device; the film packaging device is installed behind the inner and outer layer paper forming device; and the heat sealing device is installed above the film packaging device through bolts. According to the device, in the working process, automatic gluing, attaching and packaging of paper straws are achieved, automation is achieved, and manpower is saved.

Owner:QINGDAO UNIV OF SCI & TECH

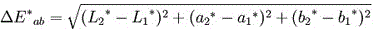

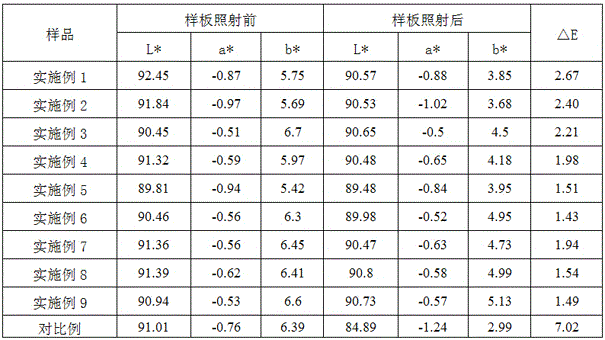

A kind of preparation method of high light resistance laminated paper titanium dioxide pigment

ActiveCN109705630BImprove retentionGood dispersant effectInorganic compound additionPigment treatment with non-polymer organic compoundsHydrated aluminaALUMINUM PHOSPHATE

The invention provides a preparation method of a high-light-resistant titanium dioxide pigment for laminated paper. The method comprises the following steps: preparing titanium dioxide slurry from a rutile-type titanium dioxide initial product prepared by adopting a chlorination process method, and adjusting the pH value to 8.5-10.5; adding a citric acid radical-containing organic substance as a dispersing agent, and performing grinding treatment; performing heating to 55-65 DEG C for coating treatment, performing coating by using a dense aluminum phosphate coating layer, performing coating byusing a loose silicon aluminum compound coating layer, and performing coating by using a loose boehmite-type hydrated aluminum oxide coating layer; performing washing by using deionized water until conductivity of a filter cake is greater than 15000 omega*cm, and performing drying; and adding amino-containing organic matter in the steaming powder process, and performing organic coating treatmentto obtain the titanium dioxide pigment for the decorative laminated paper. The method provided by the invention has the advantages that the titanium dioxide pigment prepared by the method has the characteristics of high light performance, good whiteness and a high retention rate in the laminated decorative paper, and the prepared titanium dioxide pigment has a medium color bottom phase and the advantage of easy color matching, and can be widely used in the field of the high-end laminated decorative paper.

Owner:中信钛业股份有限公司

Titanium dioxide for laminated paper with high light resistance and preparation method thereof

The invention discloses a titanium dioxide for laminated paper with high light resistance and a preparation method thereof, wherein the titanium dioxide comprises a titanium dioxide base material and a coating layer located on the surface of the titanium dioxide base material, and the coating layer sequentially includes Zinc phosphate coating layer, aluminum phosphate coating layer and aluminum hydroxide coating layer. The titanium dioxide provided by the invention has better light fastness, hiding power and hue, can be widely used in papermaking production, and is especially suitable for laminated paper with poor light fastness in the prior art.

Owner:HENAN BILLIONS NEW MATERIAL CO LTD

Method for producing polyvinyl alcohol laminated paper, polyvinyl alcohol laminated paper and cosmetic box

Provided is a method for producing a polyvinyl alcohol laminated paper, which is free of wrinkles and concave curls, whereby an aluminum vapor-deposited layer obtained by vacuum deposition of aluminum is disposed on the surface of a polyvinyl alcohol film, a water-based adhesive having a concentration of 40 to 60%, a viscosity of 500 to 4,000 mPa.s and a coverage of 3 to 5 g / m2 is applied to the reverse surface of the polyvinyl alcohol film, said polyvinyl alcohol film is laminated to a base paper, and a printed layer is formed by printing on the polyvinyl alcohol laminated paper. Alternatively, the water-based adhesive having a concentration of 40 to 60%, a viscosity of 500 to 4,000 mPa.s and a coverage of 3 to 5 g / m2 is applied to the reverse surface of the polyvinyl alcohol film, said polyvinyl alcohol film is laminated to a base paper, an aluminum deposition layer of a transfer foil obtained by vacuum deposition of aluminum is transferred to the polyvinyl alcohol film, and a printed layer is formed by printing on the polyvinyl alcohol laminated paper.

Owner:GOJO PAPER MFG CO LTD

A method for producing rutile titanium dioxide for decorative laminated paper

ActiveCN104179066BGood weather resistanceMeets high light fastness requirementsCoatings with pigmentsTitanium dioxideWeather resistanceZirconium compounds

The invention discloses a production method of rutile-type titanium dioxide for decorative laminated paper, which comprises preparing titanium dioxide primary product slurry, diluting, coating a silicon-containing compound, coating an aluminum-containing compound, aging, filtering, washing with water, Drying, calcining, crushing and other steps, which first coat a layer of silicon film on the surface of titanium dioxide and then coat a layer of aluminum film, greatly improve the weather resistance of titanium dioxide, and remove the coating by calcining and heating. The hydroxyl group on the film avoids the reaction of electron pairs and meets the high light resistance requirements of titanium dioxide in the field of decorative laminated paper, so that cheap silicon compounds can be used to replace zirconium compounds, phosphates and rare earth metals to produce high light resistance decorations Titanium dioxide for laminated paper.

Owner:XIANGYANG LOMON TITANIUM IND CO LTD

Paper laminates comprising tungsten treated titanium dioxide having improved photostability

InactiveUS20120216976A1Natural cellulose pulp/paperSpecial paperInorganic particleInorganic particles

This disclosure relates to a resin-impregnated, opaque, cellulose pulp-based sheet comprising an inorganic particle, wherein the inorganic particle comprises at least about 0.002% of tungsten, based on the total weight of the inorganic particle, and has a photostability ratio (PSR) of at least about 2, as measured by the Ag+ photoreduction rate, and color as depicted by an L* of at least about 97.0, and b* of less than about 4. The disclosure also relates to paper laminates prepared from these resin-impregnated, opaque, cellulose pulp-based sheets.

Owner:EI DU PONT DE NEMOURS & CO

Book-making equipment and a book-making method using the same

InactiveUS20070036636A1Reduce thicknessHigh bonding strengthBookbinding adhesiveBookbinding pressesTime-ConsumingPaper sheet

In a book-making equipment (1) in which laminated sheet papers (10) permit one elevational end side to be bonded on a work table to produce a booklet. The laminated sheet papers (10) are thrown into a hollow space between pressure surfaces (20) with the book-making equipment (1) stood on the work table. The laminated sheet papers (10) thus thrown into the hollow space, permit the one elevational end side or other end side to be trued up with the one elevational end side extended beyond the pressure surfaces (20) by a predetermined length. The laminated sheet papers (10) permit the one elevational end side to be clamped with the clutch pieces 2 stably stood on the work table. This makes it ready to bond the one elevational end side of the laminated sheet papers (10), and eliminating the necessity of the time-consuming labor and the special skill with a good appearance and bonding strength insured in the booklet.

Owner:TAKAHASHI HITOSHI

Laminate Pigment with Spacing Properties and High UV-Greying Stability

ActiveUS20200095427A1Excellent UV-greying resistanceIncrease coverageSurface covering paperPigmenting treatmentPolymer sciencePhotopigment

The invention relates to a titanium dioxide particle with high opacity and UV-greying resistance comprising two silica coats and at least one alumina coat, to a method for the obtaining the same, and to the use of said particle in a method for obtaining a decorative paper laminate or a décor foil. The present invention further pertains a decorative paper laminate or a décor foil containing said coated titanium dioxide particle.

Owner:KRONOS INTERNATIONAL INC

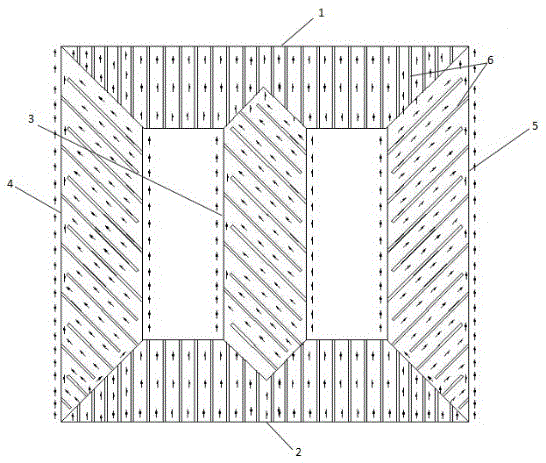

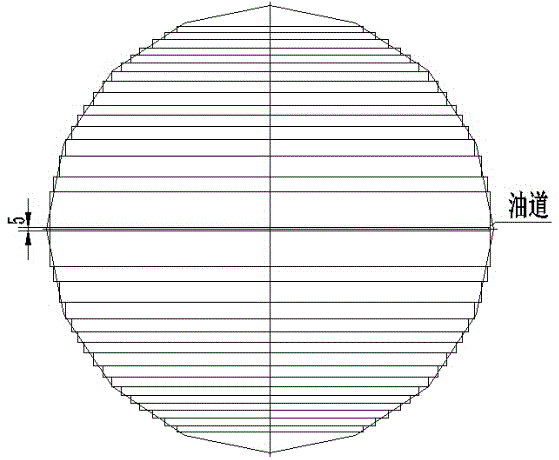

Staggered iron core oil passage structure

InactiveCN105529146AReduce temperature riseEasy to take outTransformers/inductances coolingTransformers/inductances magnetic coresThermodynamicsPaperboard

The invention relates to a staggered iron core oil passage structure. Oil passages are arranged inside a core column, an upper iron yoke and a lower iron yoke of an iron core, and a plurality of laminated paper boards are vertically and straightly placed inside the upper iron yoke and the lower iron yoke; laminated paper boards are alternately adhered onto silicon steel sheets on two sides of the core column in a 45-degree inclination manner inside the core column respectively, the laminated paper boards inside the iron column are arranged in a staggered manner, the directions of the inclination angles of the laminated paper boards adhered to two sides of the iron core are opposite, and the laminated paper boards of the iron column in the middle and the laminated paper boards of the upper iron yoke and the lower iron yoke are staggered at intervals at the joint positions of the iron column and the upper and the lower iron yokes, so that smoothness of the oil passages is guaranteed. The spacing distances among the laminated paper boards are equal. The structure adopts the design of the oil passages with 45-degree inclination angles in a transformer iron core, the oil passages are staggered to form irregularly-shaped oil passages, and finally a vortex oil flow is realized; through the structure, heat inside the transformer iron core in operation can be well taken out, and integral temperature rise of the iron core is effectively reduced. Compared with an ordinary axial or radial oil passage product, the temperature of the iron core can be reduced by more than 3K.

Owner:DALIAN XINDA TRANSFORMER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com