Biomass lamination material for lamination paper and preparation method thereof

A technology of biomass and coated paper, which is applied in the field of polymer materials, can solve the problems of oil resource consumption and environmental pollution, and achieve the effects of reducing equipment investment, simplifying the production process, and reducing prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In this embodiment, the whole biomass polyethylene with a mass fraction of 80%, 2.5% white oil, and 17.5% talcum powder are added to a high-speed mixer, stirred at 150°C for 5 minutes, and mixed evenly. The particle size of the talcum powder is 5 to 15 microns; then the mixture is added to a twin-screw extruder at 180°C for kneading and granulation to obtain a biomass coating material for coating paper.

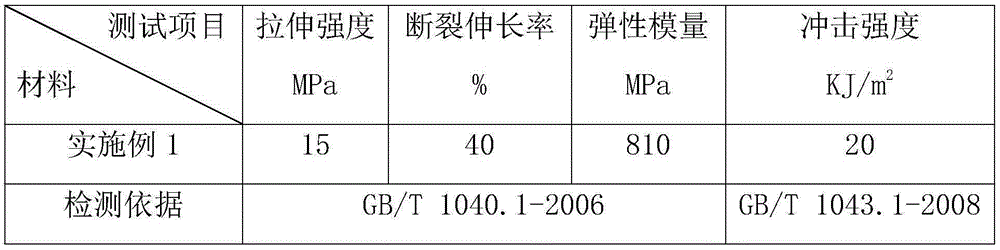

[0023] The physical properties of the biomass coating material used for coating paper prepared in this example are shown in Table 1.

[0024] Table 1:

[0025]

Embodiment 2

[0027] In this example, all biomass polyethylene with a mass fraction of 95%, 2% coconut oil, and 3% diatomaceous earth were added to a high-speed mixer, stirred at 60°C for 30 minutes, and mixed evenly, the particle size of diatomite 5-15 microns; then the mixture is kneaded and granulated in a twin-screw extruder at 220° C. to obtain a biomass coating material for coating paper.

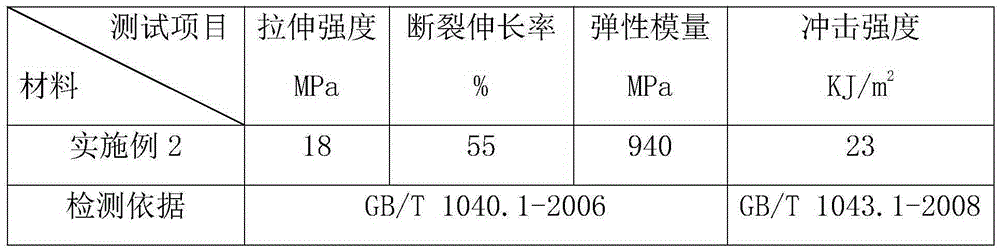

[0028] The physical properties of the biomass coating material used for coating paper prepared in this example are shown in Table 2.

[0029] Table 2:

[0030]

Embodiment 3

[0032] In this example, all biomass polyethylene with a mass fraction of 85%, 3% olive oil, and 12% silicon dioxide were added to a high-speed mixer, stirred at 100°C for 20 minutes, and mixed uniformly, the particle size of the silicon dioxide 5-15 microns; then the mixture is kneaded and granulated in a twin-screw extruder at 150° C. to obtain a biomass coating material for coating paper.

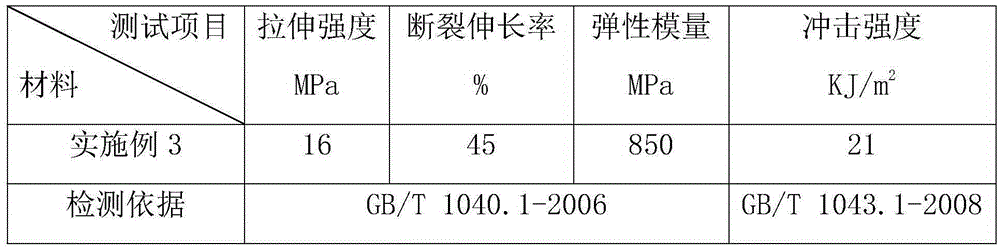

[0033] The physical properties of the biomass coating material used for coating paper prepared in this example are shown in Table 3.

[0034] table 3:

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com