Graphene/quinones composite material, preparation method and secondary cell

A composite material and secondary aluminum battery technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve the problems of poor electrical conductivity, achieve high electrical conductivity, increase utilization, and improve charge and discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

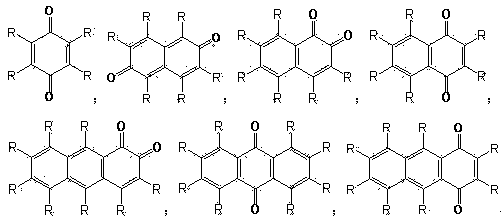

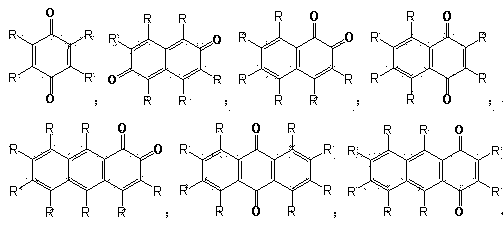

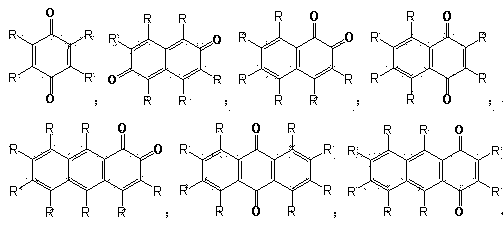

Image

Examples

Embodiment 1

[0049] 1) Pre-oxidation of graphite: Add 3g of graphite powder into 200mL of concentrated sulfuric acid, stir for 0.5h; then add 1g of phosphorus pentoxide and 3g of potassium persulfate to the above sulfuric acid solution of graphite powder, adjust the reaction temperature to 80 ℃, reacted for 6 hours, washed with ultrapure water until neutral after the reaction, and then dried in a blast drying oven at 40 ℃ for later use.

[0050]2) Preparation of graphene oxide: add pre-oxidized graphite into 150mL concentrated sulfuric acid, ultrasonically, stir and disperse for 0.5h; add 14g potassium permanganate, control the temperature below 10°C, and react for 1h; then transfer the reaction solution to 35 ℃ in a constant temperature water bath, stir for 5 hours, then transfer it to an ice-water bath, add 300mL ultrapure water to dilute, and control the temperature below 55℃; when the temperature of the reaction solution drops to room temperature, add 3mL of 30% Hydrogen peroxide, when...

Embodiment 2

[0055] Preparation of graphene / anthraquinone composite material: graphene and anthraquinone were mixed at a mass ratio of 3:7, added to a ball mill, ball milled at a speed of 250r / min for 5h, and the ball milled product was collected for later use.

[0056] The battery preparation and testing methods are the same as in Example 1.

[0057] The open circuit voltage of the battery is 1.78V, the maximum discharge capacity is 534mAh, and the discharge capacity after 50 charge-discharge cycles is 359mAh.

Embodiment 3

[0059] Preparation of graphene / naphthoquinone composite material: Graphene and naphthoquinone were mixed at a mass ratio of 3:7, added to a ball mill, ball milled at a speed of 250r / min for 8 hours, and the milled product was collected for later use.

[0060] The battery preparation and testing methods are the same as in Example 1.

[0061] The open circuit voltage of the battery is 1.78V, the highest discharge capacity is 558mAh, and the discharge capacity after 50 charge-discharge cycles is 362mAh.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com