Construction method based on technology for producing boron isotope by anisole-boron trifluoride

A technology of boron trifluoride and anisole, applied in the field of isotope separation, can solve the problems of low yield of boron-10, unable to obtain qualified products of boron-11 at the same time, etc., so as to improve separation efficiency, shorten start-up time and start-up time short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The raw materials used are boron trifluoride gas (natural abundance, that is, boron-10 abundance of 19.3%) and anisole liquid, and the molar ratio of the boron trifluoride gas and anisole liquid is 1: 1;

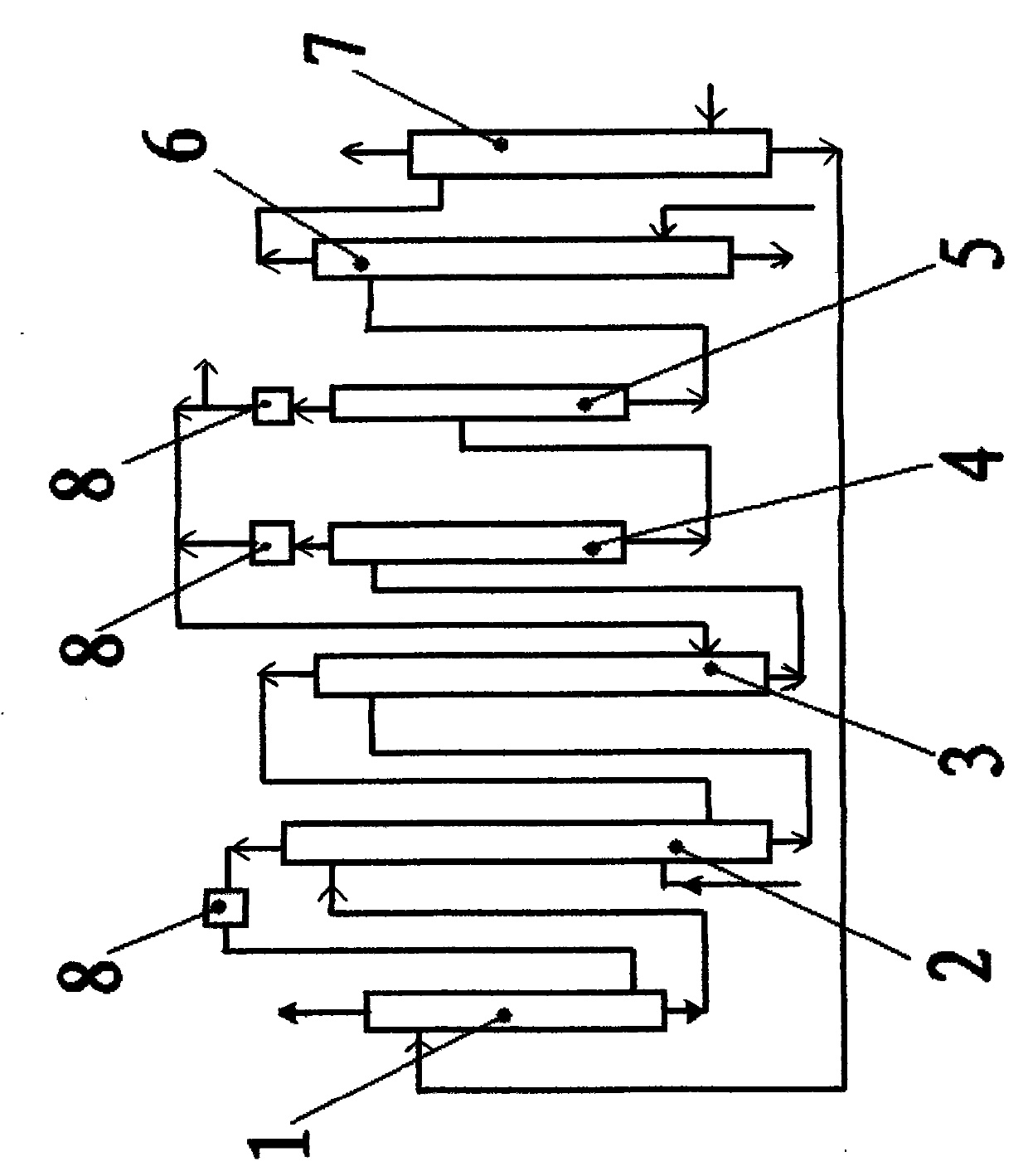

[0023] With reference to the drawings, the equipment used includes complexing tower 1, first exchange rectification tower 2, second exchange rectification tower 3, complex stripping tower 4, complex cracking tower 5, anisole rectification Impurity removal tower 6, anisole drying tower 7, cold box 8, etc.;

[0024] The method is: the system is purged and replaced with nitrogen without residual moisture. Set the system pressure to 5Kpa(G) or 10Kpa(G) or 20Kpa(G) or 35Kpa(G) or 50Kpa(G) or 70Kpa(G) or 85Kpa(G), the suitable pressure is 10Kpa(G), the system uses Nitrogen press to maintain pressure. All storage tanks are sealed and protected with low pressure nitrogen and positive pressure to prevent the ingress of moist air.

[0025] Purify the raw material boron trifluoride...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com