Cerium-doped catalyst material as well as preparation method and application thereof

A catalyst and cerium-doped technology, which is applied in the field of preparation of cerium-doped catalyst materials, and achieves the effects of simple preparation method, efficient degradation, and simple and feasible synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The catalyst of the present invention is a doped catalyst. where the main component is MoO 3 , the modified doping component is CeO 2 . Doped Catalyst Ce / MoO 3 The preparation method adopts the hydrothermal method combined with the impregnation and calcination method, that is, the hydrothermal method synthesizes MoO 3 , and prepared Ce / MoO by impregnation and calcination 3 doped material.

[0036] Dissolve 0.6180g of ammonium molybdate in 10ml of water, stir to dissolve, then add 1.59ml of dilute nitric acid with a concentration of 2.2mol / L, stir for 3 minutes, transfer the solution into a 60ml autoclave, and heat the autoclave to 180 °C, remove after 24 hours. After cooling to room temperature, wash 3 times with distilled water, centrifuge and precipitate, and heat the solid powder at 120°C for 3 h to dry to obtain MoO 3 sample.

[0037] Weigh 0.15g of the above MoO 3 Add 1.66ml of cerium nitrate solution with a concentration of 11.4mg / ml to the sample, add wa...

Embodiment 2

[0039] The catalyst of the present invention is a doped catalyst. where the main component is MoO 3 , the modified doping component is CeO 2 . Doped Catalyst Ce / MoO 3 The preparation method adopts the hydrothermal method combined with the impregnation and calcination method, that is, the hydrothermal method synthesizes MoO 3 , and prepared Ce / MoO by impregnation and calcination 3 doped material.

[0040] Dissolve 0.6180g of ammonium molybdate in 10ml of water, stir to dissolve, then add 1.59ml of dilute nitric acid with a concentration of 2.2mol / L, stir for 3 minutes, transfer the solution into a 60ml autoclave, and heat the autoclave to 180 °C, remove after 24 hours. After cooling to room temperature, wash 3 times with distilled water, centrifuge and precipitate, and heat the solid powder at 120°C for 3 h to dry to obtain MoO 3 sample.

[0041] Weigh 3 parts of 0.15g of the above sample, add 3.32ml, 6.64ml, 13.28ml of cerium nitrate solution (concentration: 11.4mg / ml)...

Embodiment 3

[0043] Novel Ce-doped MoO disclosed by the present invention 3 Catalyst, which can efficiently degrade environmental organic pollutants without light and without heating, and the degradation activity of the optimal doping amount is higher than that of pure phase MoO 3 The improvement is more than 100 times, and has a good application prospect.

[0044] The sample can degrade the subcationic dye methylene blue, the anionic methyl orange, and the application of mixed dyes at room temperature.

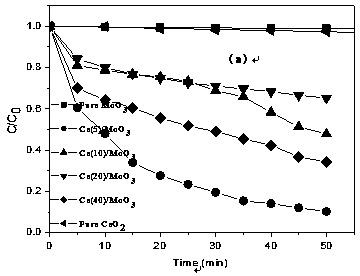

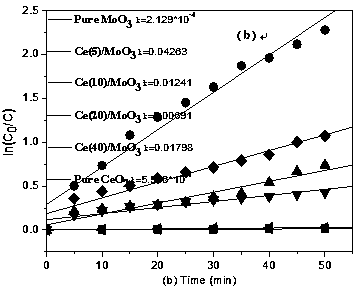

[0045] figure 1 , figure 2With methylene blue as the characteristic pollutant, the doped catalyst was added under the condition of normal temperature and pressure without any oxygenation equipment, and the catalytic degradation activity of different doping amounts was investigated. figure 1 The middle abscissa is the degradation time, and the ordinate is the degradation ratio of methylene blue.

[0046] Depend on figure 2 middle k The degradation activity of the optimal doping a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com