A kind of preparation method of porous metal matrix composite solder alloy brazing joint

A technology of porous metal and composite brazing filler metal, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problem that the joint welding rate is difficult to guarantee, the overall mechanical properties of the joint are poor, and the molten brazing alloy is difficult to wet. Spreading and other problems to achieve the effect of improving the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

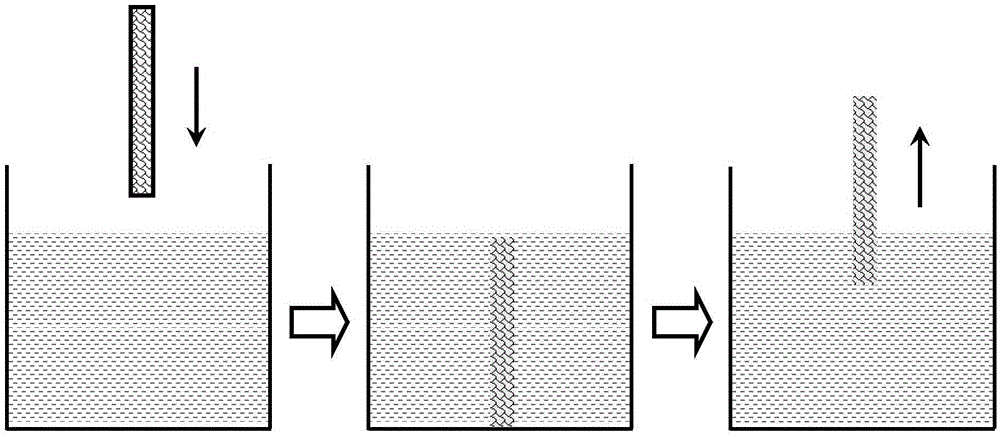

[0039] see figure 1 , take a piece of porous Ni foil with a thickness of 250 μm and a size of 20 mm × 20 mm, place the porous Ni foil in absolute ethanol for ultrasonic cleaning, and then immerse the Ni foil in molten pure Sn and shake it several times after air-drying. Take out the porous Ni foil, and now pure Sn has been impregnated in the porous Ni metal foil, and a porous Ni-based composite solder sheet filled with pure Sn has been formed;

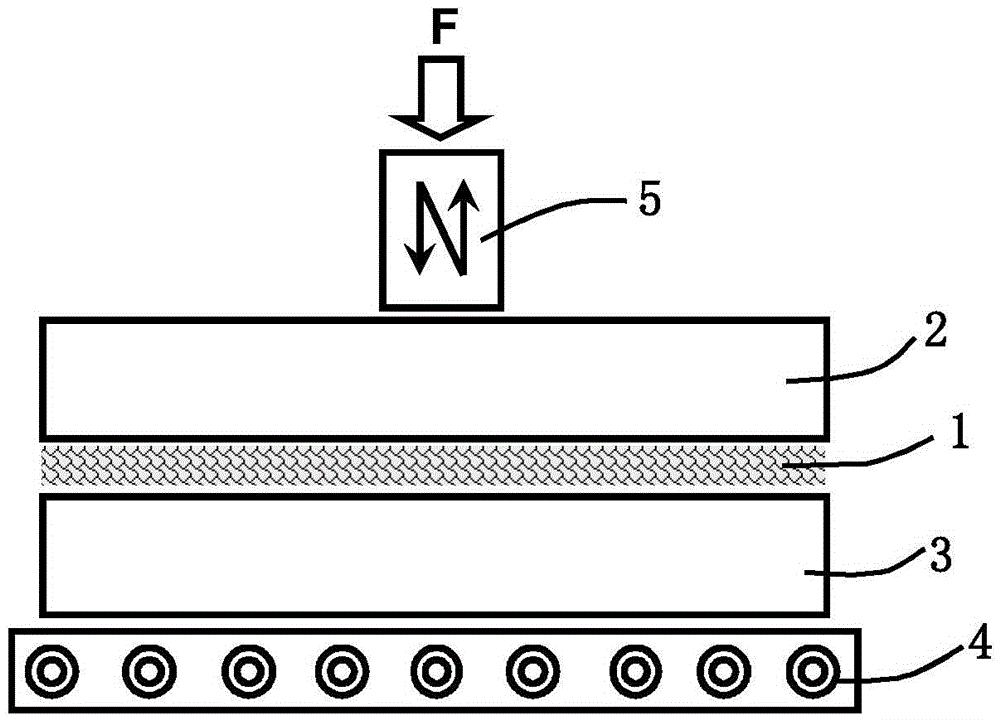

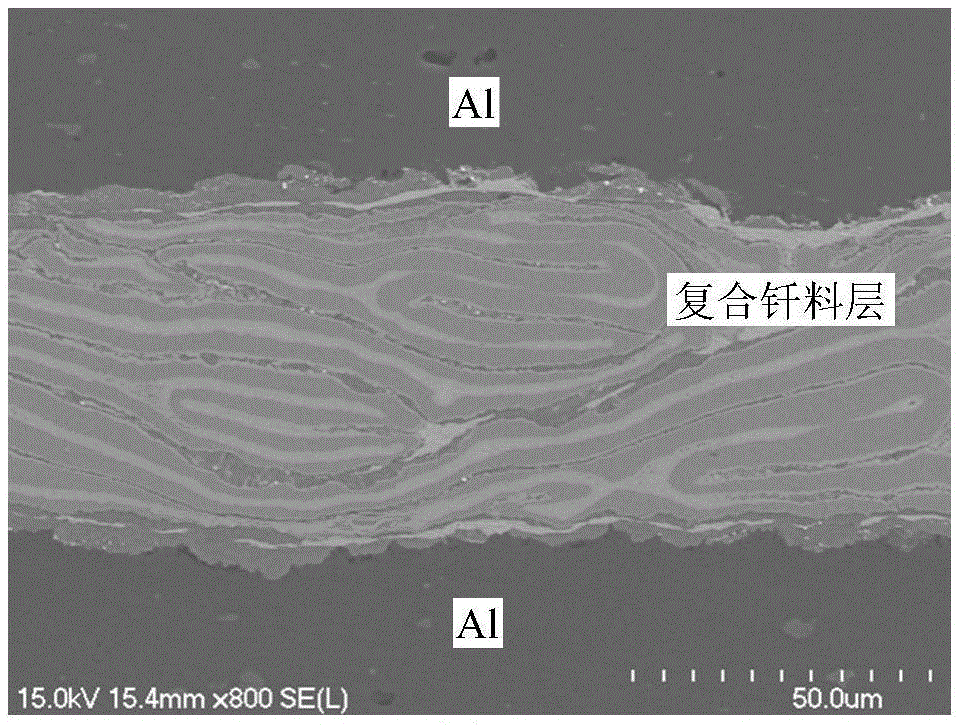

[0040] see figure 2 , take two pieces of 1060-Al alloy with a size of 20mm×20mm×3mm, place the composite solder piece 1 between the upper Al base material 2 and the lower Al base material 3, and place the assembled joint with a restraint Fixture on hot plate 4. Apply the tool head 5 of the ultrasonic vibration device to the surface of the upper Al base material 2 and apply a pressure of 1 MPa, then turn on the heating device to heat the joint, and when the solder alloy starts to melt and overflow, turn on the ultrasonic vibration. T...

Embodiment 2

[0043] see figure 1 , take a piece of porous Ni foil with a thickness of 100 μm and a size of 10 mm × 10 mm, place the porous Ni foil in absolute ethanol for ultrasonic cleaning, air-dry and then immerse the Ni foil in molten pure Sn and shake it several times, then Take out the porous Ni foil, at this time pure Sn has been impregnated in the porous Ni metal foil, and a porous Ni-based composite solder sheet filled with pure Sn has been formed, and finally, the composite solder sheet is cut into a diameter of round brazing sheet.

[0044] see Figure 4, take the diameter as Two T2-Cu metal rods with a length of 40mm are assembled with the Cu rod and the composite solder alloy sheet 1, wherein the lower Cu rod 32 is fixed by the clamp, and the upper Cu rod 22 has a degree of freedom along the direction of the Cu rod axis, The composite solder alloy sheet 1 is placed between two Cu rods, the tool head 5 of the ultrasonic vibration device is applied to the end of the upper C...

Embodiment 3

[0047] see figure 1 , take a piece of porous Ni foil with a thickness of 200 μm and a size of 10 mm × 10 mm, place the porous Ni foil in absolute ethanol for ultrasonic cleaning, air-dry and then immerse the Ni foil in molten pure Sn and shake it several times, then The porous Ni foil is taken out, and the pure Sn has been infiltrated into the porous Ni metal foil at this time, and a porous Ni-based composite solder sheet filled with pure Sn is formed.

[0048] see Figure 6 , take a piece of 1060-Al alloy and a T2-Cu alloy with a size of 10mm×10mm×3mm, place the composite solder sheet 1 between the Al base material 23 and the Cu base material 33, and place the assembled joint On the electric heating plate 4 with a limiting fixture, in which the Al base material 23 is on the top and the Cu base material 33 is on the bottom, the tool head 5 of the ultrasonic vibration device is applied to the upper surface of the Al base material 23 and a pressure of 2 MPa is applied, and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com