A kind of method for preparing chromium trichloride hexahydrate with sodium chromate

A technology of chromium trichloride hexahydrate and chromium trichloride, applied in the chemical field, can solve the problems of producing toxic and harmful gases, hindering the occupational health of operators, long process flow, etc., so as to reduce the harm of hexavalent chromium to the human body. , broad market prospects and value profits, the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Add 0.78L of sodium chromate aqueous solution with a mass concentration of 300g / L and 20.25mL of methanol with a concentration of 99% (1 times the theoretical amount) into the reaction vessel with condensing reflux, and control the temperature to rise to 118°C. Slowly add 174.66mL of hydrochloric acid with a concentration of 37% (1 times the theoretical amount) dropwise within 15 minutes; after adding hydrochloric acid, control the temperature at 120°C for 1 hour, mature at 100°C for 1 hour, add alkaline solution to neutralize the reaction solution to pH =6.8, filter to obtain the intermediate product with chromium hydroxide as the main component; the intermediate product is washed and added with a concentration of 36% hydrochloric acid 281.13mL to react, evaporated and concentrated until the concentration of chromium trichloride reaches 42 Baume degrees, Natural cooling and crystallization, centrifugation and drying at 67°C to obtain chromium trichloride hexahydrate.

...

Embodiment 2

[0051] Add 0.78L of sodium chromate aqueous solution with a mass concentration of 300g / L and 60.75mL of methanol with a concentration of 99% (3 times the theoretical amount) into a reaction vessel with condensing reflux, and control the temperature to rise to 120°C. Slowly add 349.33mL of hydrochloric acid (twice the theoretical amount) with a concentration of 37% dropwise within 20 minutes; after adding hydrochloric acid, control the temperature at 110°C for 2h, mature at 90°C for 1h, add alkaline solution to neutralize the reaction solution to pH =7, filter to obtain an intermediate product with chromium hydroxide as the main component; add 295.24mL of hydrochloric acid with a concentration of 36% to react after the intermediate product is washed, evaporate and concentrate until the concentration of chromium trichloride reaches 45 Baume degrees, Natural cooling and crystallization, centrifugation and drying at 65°C to obtain chromium trichloride hexahydrate.

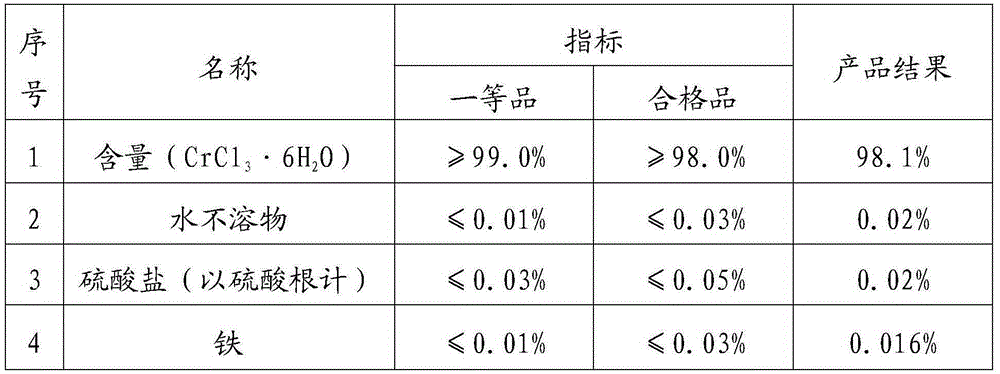

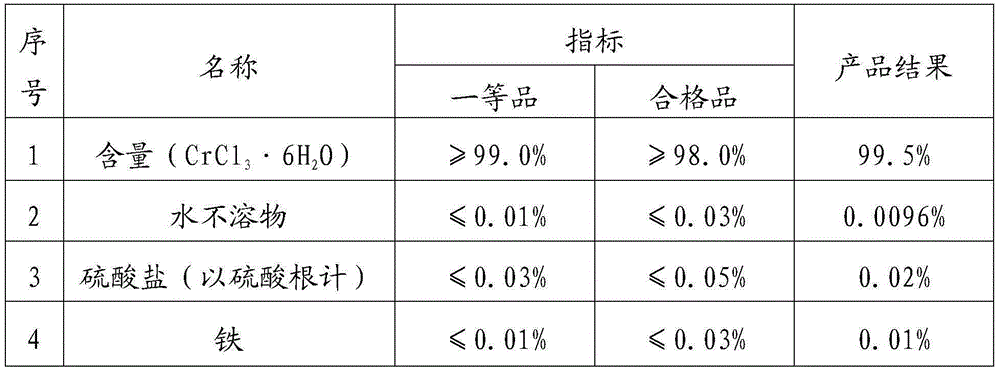

[0052] Table t...

Embodiment 3

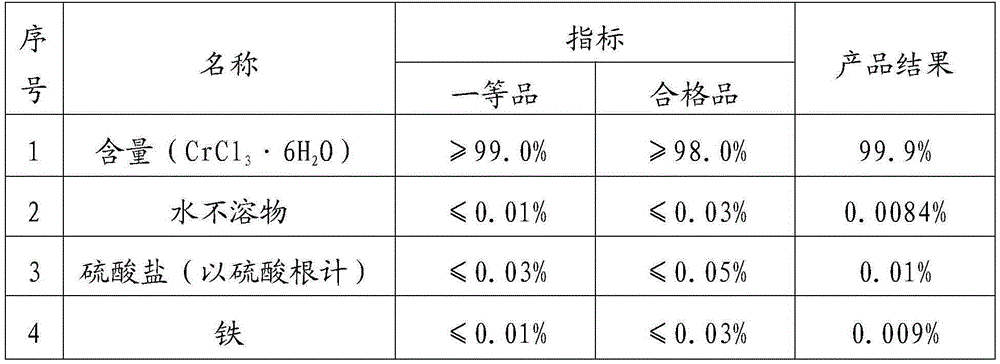

[0057] Add 0.78L of sodium chromate aqueous solution with a mass concentration of 300g / L and 40.5mL of methanol with a concentration of 99% (twice the theoretical amount) into the reaction vessel with condensing reflux, and control the temperature to rise to 120°C, with stirring Slowly add 262mL of hydrochloric acid with a concentration of 37% (1.5 times the theoretical amount) dropwise within 25 minutes; after adding hydrochloric acid, control the temperature at 120°C for 4 hours, mature at 100°C for 4 hours, add alkaline solution to neutralize the reaction solution to pH =7, filter to obtain an intermediate product with chromium hydroxide as the main component; the intermediate product is washed and added with a concentration of 36% hydrochloric acid 288.68mL to react, evaporated and concentrated until the concentration of chromium trichloride reaches 45 Baume degrees, Natural cooling and crystallization, centrifugation and drying at 65°C to obtain chromium trichloride hexahy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com