Sludge drying sewage treatment system and method

A technology of sewage treatment system and sewage treatment method, applied in water/sludge/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. Water quality deterioration and other problems, to achieve the effects of low excess sludge production, improved system nitrification efficiency, and increased hydraulic retention time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

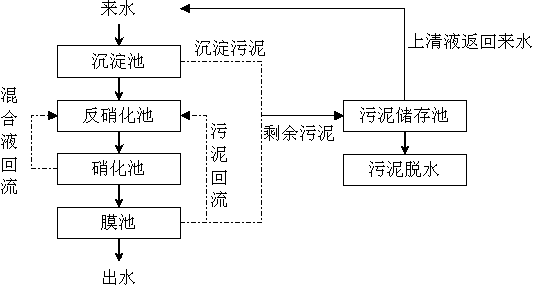

[0058] 1) After the wastewater is settled in the sedimentation tank, the mud and water are separated. The sludge is sent to the sewage treatment system for treatment. The supernatant overflows into the nitrification and denitrification system. After sedimentation and separation, most of the suspended solids are removed, and the concentration of suspended solids is reduced. At the same time, most of the organic pollutants contained in the suspended solids are removed, which greatly reduces the organic load of subsequent treatment facilities.

[0059] 2) The supernatant overflows into the nitrification-denitrification system. Wastewater after carbon removal and nitrification, which is considered to contain a large amount of nitrate nitrogen and nitrite nitrogen after nitrification, is transported from the end of the nitrification tank to the nitrification mixture at the front of the denitrification tank through the mixed liquid return pump, In the denitrification pool, denitri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com