Low-porosity high-freezing-resistance gelatinizer and preparation method thereof

A technology with high porosity and high frost resistance, which is applied in the field of building materials to achieve the effects of small pore size, improved microstructure and morphology, and improved frost resistance durability and crack resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

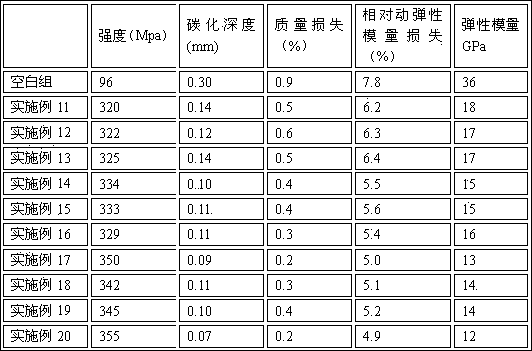

Examples

preparation example Construction

[0029] The present invention also relates to a preparation method of a low porosity high frost resistance gelling agent, the steps are as follows:

[0030] (1) Mix the composite water reducer composed of polycarboxylate water reducer and aliphatic water reducer with a weight ratio of 1~4:1 and the composite retarder composed of sodium gluconate and sodium hexametaphosphate to obtain Mixture a, the mass fraction of the composite water reducer is 4 to 10 parts, and the mass fraction of the composite retarder is 2 to 5 parts;

[0031] (2) Mix 42-48 parts by mass of superfine slag powder, 24-30 parts of silicon micropowder, 10-15 parts of expansion agent, 2-3 parts of short steel fiber and 1-3 parts of heavy carbonic acid The calcium powder is mixed evenly to obtain the mixture b;

[0032] (3) Uniformly mixing the mixture a obtained in step (1) and the mixture b obtained in step (2) to obtain a gelling agent with low porosity and high frost resistance.

[0033] The present inven...

Embodiment 1

[0044] A low porosity and high frost resistance gelling agent, consisting of 42 parts by mass of superfine slag powder, 30 parts of silicon micropowder, 15 parts of expansion agent, 2 parts of polycarboxylate water reducer and 2 parts of Composite shrinking agent composed of aliphatic water reducer, composite retarder composed of 1 part of sodium gluconate and 1 part of sodium hexametaphosphate, 2 parts of short steel fiber, 1 part of heavy calcium carbonate powder, 2 parts Microcrystalline cellulose and 3 parts of dioctyl sodium sulfosuccinate.

Embodiment 2

[0046] A low porosity and high frost resistance gelling agent, consisting of 48 parts by mass of superfine slag powder, 24 parts of silicon micropowder, 10 parts of expansion agent, 8 parts of polycarboxylate water reducer and 2 parts of Composite shrinking agent composed of aliphatic water reducer, composite retarder composed of 4 parts of sodium gluconate and 1 part of sodium hexametaphosphate, 3 parts of short steel fiber, 3 parts of heavy calcium carbonate powder, 4 parts microcrystalline cellulose and 1 part of dioctyl sodium sulfosuccinate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com