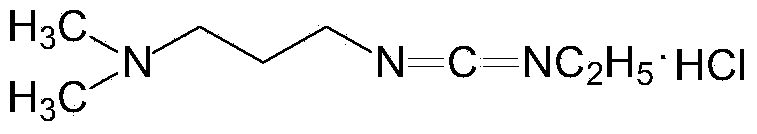

Preparation method of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride

A technology of ethylcarbodiimide hydrochloride and dimethylaminopropyl, applied in the field of preparation of 1--3-ethylcarbodiimide hydrochloride, can solve the problem of unsuitability for industrial production and low yield etc. to achieve high conversion rate, high total yield and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

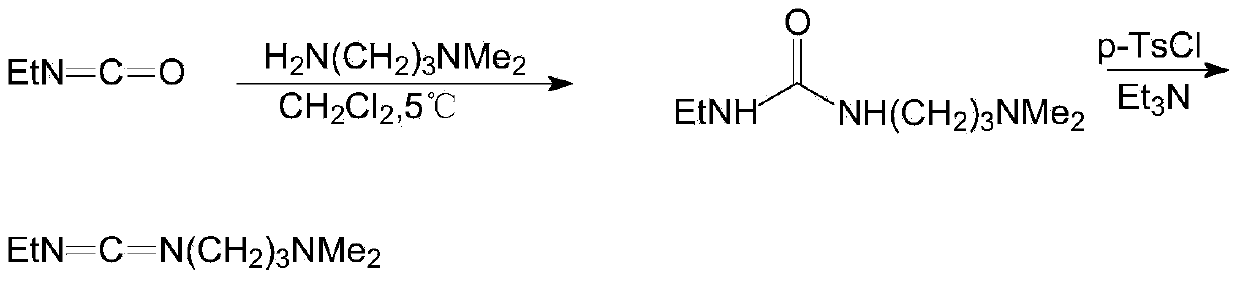

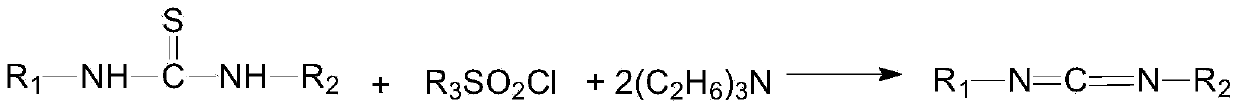

Method used

Image

Examples

Embodiment 1

[0047] Weigh 12ml of carbon disulfide and dissolve it in 100ml of methanol, slowly add 20.4g of N,N'-dimethylpropylenediamine dropwise, control the temperature at 10-15°C, a white solid is formed during the dropping process, and the dropping is completed in 10-15 Incubate at °C for 1 hour, filter, and wash with methanol to obtain 38 g of white solid (Intermediate 1), with a yield of 95%.

[0048] Weigh 38g of the product from the previous step, add 120ml of chloroform, control the temperature at 10-15°C, add 24.2g of triethylamine, then slowly add 11.1g of ethyl chloroformate dropwise, dropwise for 1 hour, keep the temperature for 1 hour after the dropwise addition, until Dissolve, wash the organic phase, filter and dry to obtain the product (intermediate 2).

[0049] Weigh 12.9g of ethylamine (containing 70% water), add 60ml of chloroform, cool down to 10-15°C, slowly add intermediate 2 dropwise, keep warm for 1 hour after the dropwise addition, and wash the organic phase wit...

Embodiment 2

[0052] Weigh 24ml of carbon disulfide and dissolve it in 150ml of methanol, slowly add 43.8g of N,N'-dimethylpropylenediamine dropwise, control the temperature at 10-15°C, a white solid will form during the dropwise addition, and keep warm at 20°C after the dropwise addition After 2 hours, it was filtered and washed with methanol to obtain 75 g of white solid (Intermediate 1), with a yield of 96%.

[0053]Weigh 75g of the product from the previous step, add 200ml of dichloromethane, control the temperature at 10-15°C, add 45.8g of triethylamine, then slowly add 50.3g of ethyl chloroformate dropwise, dropwise for 2 hours, and keep warm for 1 hour after the dropwise addition , until dissolved, the organic phase was washed, filtered, and dried to obtain the product (intermediate 2).

[0054] Weigh 25.2g of ethylamine (containing 70% water), add 180ml of dichloromethane, cool down to 10-15°C, slowly add intermediate 2 dropwise, keep warm for 1 hour after the dropwise addition, and...

Embodiment 3

[0057] Weigh 24ml of carbon disulfide and dissolve it in 150ml of chloroform, slowly add 41.5g of N,N'-dimethylpropylenediamine dropwise, control the temperature at 10-15°C, keep the temperature at 15°C for 1 hour after the addition, and concentrate under reduced pressure to obtain White solid 72.4 g (Intermediate 1).

[0058] Add 180ml of chloroform to the white solid product 72.4 of the previous step, control the temperature at 10-15°C, add 41.2g of triethylamine, then slowly add 48.9g of ethyl chloroformate dropwise, dropwise for 2 hours, and keep warm for 1 hour after the dropwise addition is completed. To dissolve, wash the organic phase, filter, and dry to obtain the product (intermediate 2).

[0059] Weigh 26.2g of ethylamine (containing 70% of water), add 150ml of dichloromethane, cool down to 10-15°C, slowly add intermediate 2 dropwise, keep warm for 1 hour after the dropwise addition, and wash with lye with pH = 11-12 The organic phase was dried, reduced pressure, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solubility (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com