Controllable-acid-value photosensitive alkali-soluble polyurethane acrylate resin and photoresist composition thereof

A technology of urethane acrylate and photosensitive alkali, applied in the field of ultraviolet light curing, can solve the problems of high viscosity, low activity, and a large number of diluents, and achieve the effect of high resolution and good comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Synthesis of photosensitive alkali-soluble urethane acrylate resin: add isophorone diisocyanate (IPDI) 44.46g and dibutyltin dilaurate in a 250ml four-necked round-bottomed flask equipped with a thermometer, a reflux condenser, and a stirrer (DBTDL) 0.019g, and then add 24.22g of N,N-dimethylformamide (DMF), raise the temperature to 80°C, and then add 13.40g of 2,2-dimethylolpropionic acid (DMPA) three times. The degree of reaction was measured by toluene-di-n-butylamine back titration until the NCO group content reached the theoretical value, and the theoretical value was reached at 80°C for 2 hours, then the temperature was lowered to 75°C, and polymerization inhibitors 2 and 6 were added to it. -Di-tert-butyl p-cresol 0.15g, then add 39.00g of hydroxyethyl methacrylate (HEMA), until no NCO can be detected at 2265cm by infrared spectrum -1 At the time of the absorption peak, stop the reaction, the required time is 5h, and obtain the photosensitive alkali-soluble u...

Embodiment 2

[0022] (1) Synthesis of photosensitive alkali-soluble urethane acrylate resin: add toluene diisocyanate (TDI) 34.83g and dibutyltin dilaurate (DBTDL) in a 250ml four-neck round bottom flask equipped with a thermometer, a reflux condenser, and a stirrer 0.017g, then 24.22g of N,N-dimethylformamide (DMF) was added, the temperature was raised to 70°C, and 13.40g of 2,2-dimethylolpropionic acid (DMPA) was added three times. The degree of reaction was measured by the toluene-di-n-butylamine back titration method until the NCO group content reached the theoretical value, and the theoretical value was reached at 70 ° C for 2.5 hours, then the temperature was raised to 75 ° C, and polymerization inhibitor 2 was added thereto. 0.13g of 6-di-tert-butyl-p-cresol, then add 39.00g of hydroxyethyl methacrylate (HEMA), until no NCO can be detected at 2265cm -1 At the time of the absorption peak, stop the reaction, the required time is 4.5h, and obtain the photosensitive alkali-soluble uretha...

Embodiment 3

[0025] (1) Synthesis of photosensitive alkali-soluble urethane acrylate resin: add isophorone diisocyanate (IPDI) 44.46g and dilauric acid di Butyltin (DBTDL) 0.021g, then N,N-dimethylformamide (DMF) 25.90g was added, the temperature was raised to 80°C, and 2,2-dimethylolpropionic acid (DMPA) 17.42g was added three times. The degree of reaction was measured by the toluene-di-n-butylamine back titration method until the NCO group content reached the theoretical value, and the theoretical value was reached at 80°C for 2.5 hours, then the temperature was lowered to 75°C, and polymerization inhibitor 2 was added thereto. 0.16g of 6-di-tert-butyl p-cresol, 41.72g of pentaerythritol triacrylate (PETA), until NCO can not be detected at 2265cm by infrared spectrum -1 At the time of the absorption peak, stop the reaction, the required time is 5.5h, and obtain the photosensitive alkali-soluble urethane acrylate resin.

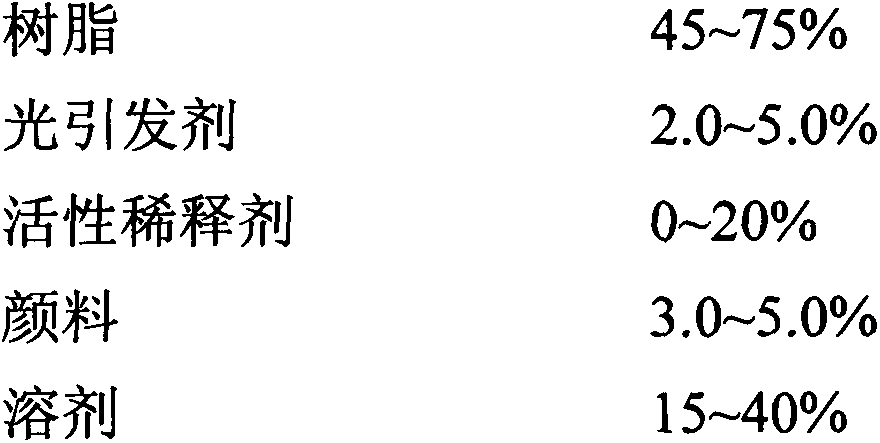

[0026] (2) Preparation and development test of photoresist composi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com