Preparation method, material and application of porous polymer

A porous polymer and polymer technology, applied in the field of polymer materials, can solve the problems of high production cost of porous materials, complex synthesis process, etc., and achieve the effects of reducing process complexity, simple synthesis method and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

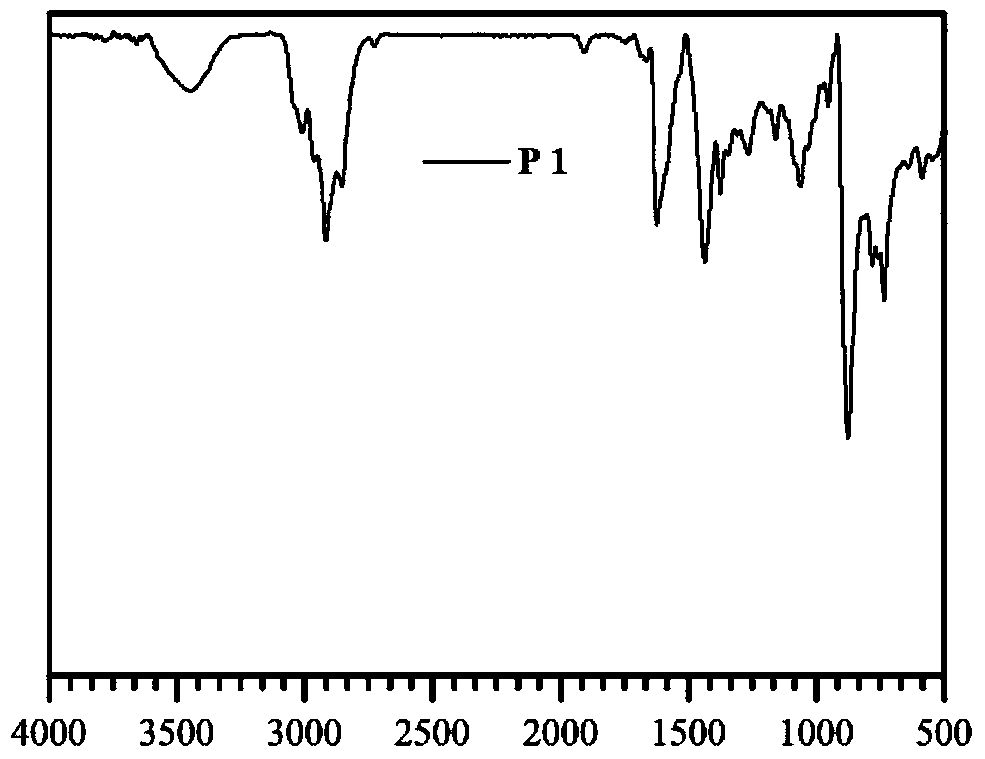

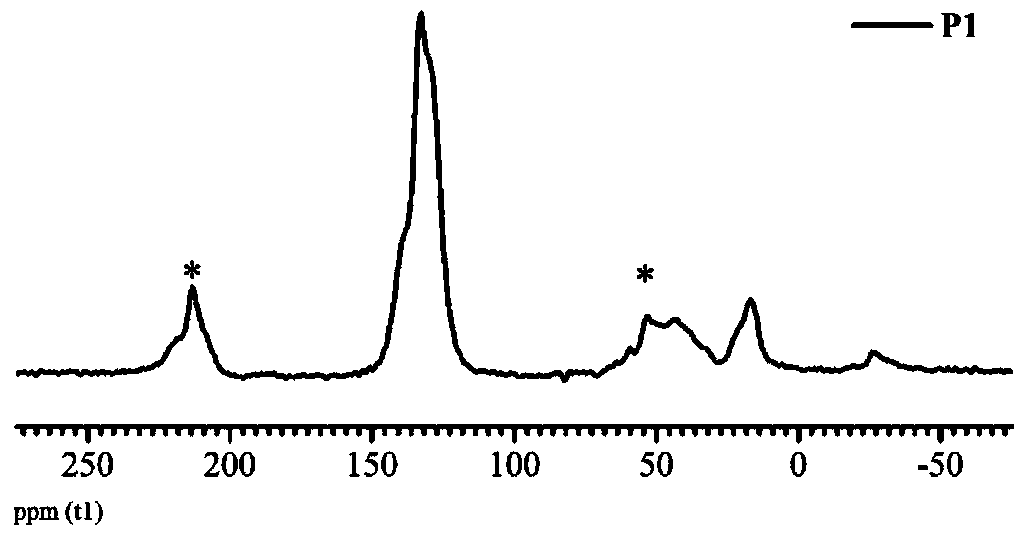

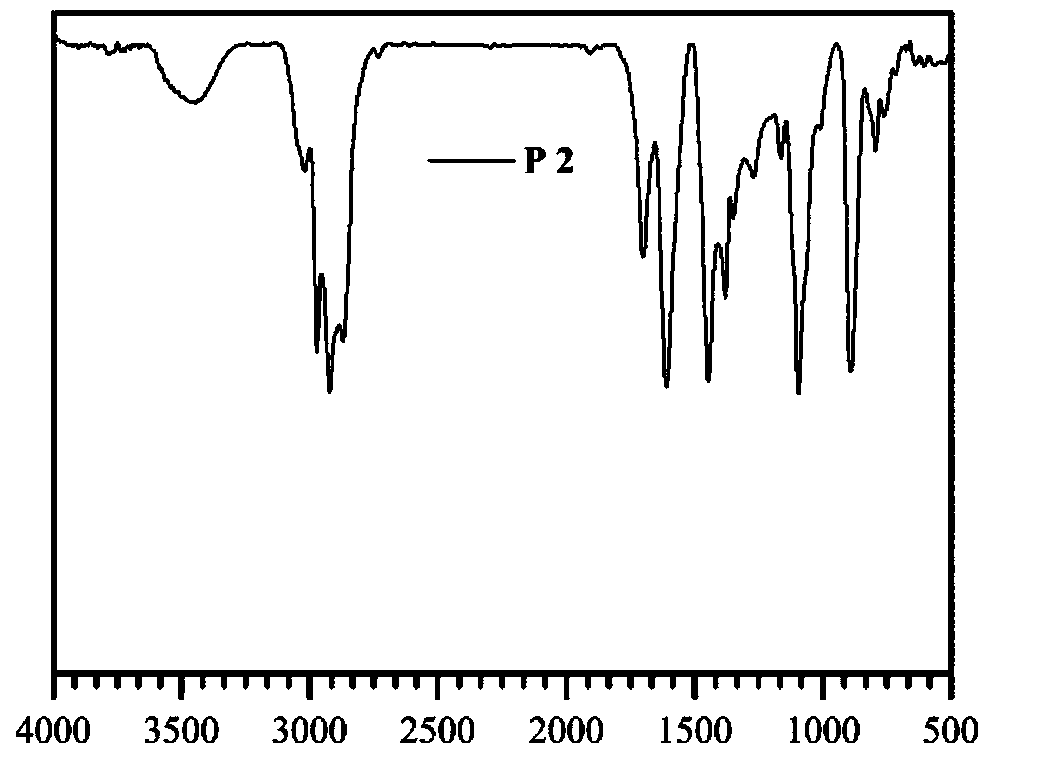

Image

Examples

preparation example Construction

[0061] The preparation method of porous polymer provided by the invention comprises the following steps:

[0062] (1) Preparation of raw material mixture: use aromatic compounds, their mixtures, their polymers and / or their polymer mixtures as raw materials, and uniformly disperse the raw materials in a crosslinking agent and solvent to obtain a raw material mixture. The raw material concentration is between 0.01g / ml and 10g / ml. The crosslinking agent and solvent is a mixture of one or more dihalogen substituted alkanes.

[0063] Different aromatic compounds or their polymers are used to obtain organic porous polymer materials containing different functional groups, and the content of the functional groups is regulated by changing the ratio of the various aromatic compounds or their polymers used.

[0064] (2) Preparation of porous polymer: add a catalyst to the raw material mixture obtained in step (1), and Friedel-Crafts reaction occurs to obtain a crude product through hype...

Embodiment 1

[0075] A method for preparing a porous polymer, comprising the steps of:

[0076] (1) Preparation of raw material mixture: use benzene as raw material, dichloromethane as cross-linking agent and solvent, under nitrogen protection, add raw materials and cross-linking agent and solvent in a three-necked flask equipped with a reflux condenser and a thermometer, and magnetically stir After 0.2 hours, a raw material mixture was obtained with a raw material concentration of 0.095 g / ml.

[0077] (2) Preparation of porous polymer: take anhydrous aluminum trichloride as a catalyst, add the catalyst to the raw material mixed solution obtained in step (1), so that the ratio of the molar number of benzene rings in the catalyst to the raw material is 2:1, and Friedel-Crafts reaction, hypercrosslinking to obtain the crude product.

[0078] Keep stirring continuously during the Friedel-Crafts reaction, and control the temperature after adding the catalyst. The specific process is: raise the...

Embodiment 2

[0084] A method for preparing a porous polymer, comprising the steps of:

[0085] (1) Preparation of raw material mixed solution: use biphenyl as raw material, dichloromethane as crosslinking agent and solvent, under nitrogen protection, add raw materials and crosslinking agent and solvent in a three-necked flask equipped with a reflux condenser and a thermometer, and magnetically Stir for 0.2 hours to obtain a raw material mixture with a raw material concentration of 0.095 g / ml.

[0086] (2) Preparation of porous polymer: take anhydrous aluminum trichloride as a catalyst, and then add the catalyst in the raw material mixed solution obtained in step (1), so that the ratio of benzene ring moles in the catalyst and the raw material is 2:1, A Friedel-Crafts reaction occurs, and the crude product is obtained by hypercrosslinking.

[0087] Keep stirring continuously during the Friedel-Crafts reaction, and control the temperature after adding the catalyst. The specific process is: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com