Method and device for preparing high-boiling silicon oil

A technology for high-boiling silicone oil and high-boiling substance, which is applied in the field of preparing high-boiling silicone oil, can solve the problems of limited industrialization and application, high viscosity of high-boiling silicone oil, difficult filtration operation, etc., so as to increase added value, reduce dosage and improve production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

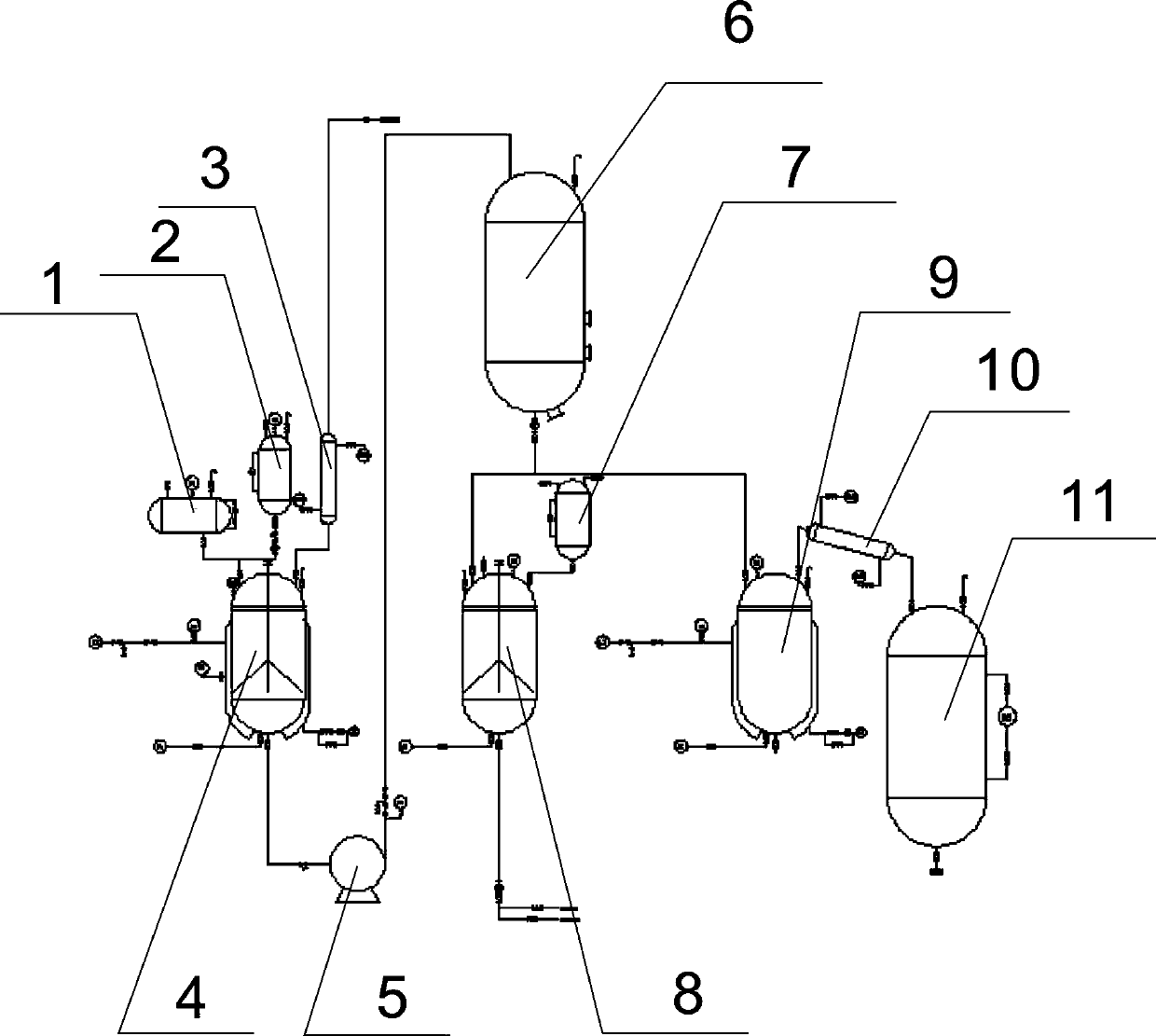

Image

Examples

Embodiment 1

[0022] Add 100 parts by weight of high boilers in the organic silicon slurry to the enamel reaction kettle, start the reaction kettle to stir, and add ethanol and water mixed solvent (ethanol:water (V / V)=1:0.1) to the kettle dropwise at room temperature 60 Parts by weight, control the reaction speed, the hydrogen chloride gas produced by the reaction is sent to the water washing tower for absorption and treatment; after the ethanol water solvent is added dropwise, raise the temperature of the reaction kettle to 75°C, open the compressed air valve at the bottom of the kettle, control the air flow rate, and continue the reaction 2h; The liquid after the complete reaction is transported to the high level tank of the acid separation by a magnetic pump to stand for stratification, and the crude acidic silicone oil and glycolic acid solution are obtained; the glycolic acid solution is injected into the ethanol distillation tank for purification and then reacts with the high boiler aga...

Embodiment 2

[0024] Other implementation conditions are the same as 1. When ethanol and water are mixed solvents (ethanol: water (V / V) = 1:0.3), the viscosity of the obtained high boiling silicone oil (25°C, mm 2 / s): 42.36, Refractive index (25°C): 1.4456.

Embodiment 3

[0026] Other implementation conditions are the same as 1. When ethanol and water are mixed solvents (ethanol: water (V / V) = 1:0.01), the viscosity of the obtained high-boiling silicone oil (25°C, mm 2 / s): 19.47, Refractive index (25°C): 1.4489.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com