Biodegradable high-barrier plastic film material and preparation method thereof

A plastic film and biodegradable technology, which is applied in polyether coatings, fibrous fillers, dyed low-molecular organic compounds, etc., can solve the problems of high price, hindering the widespread use of plastic packaging materials, narrow processing window, etc., and achieve high barrier Performance, good biodegradability, simple and effective method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

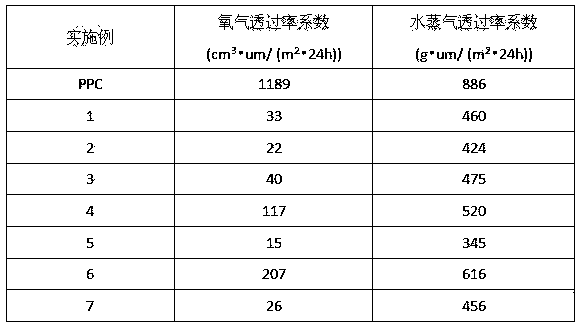

Embodiment 1

[0040] Put 1.0 g of montmorillonite organically modified by quaternary ammonium salts into 100 ml of deionized water, ultrasonicate for 2 hours at a frequency of 50KHz, seal the system and stir vigorously at a speed of 120rpm for one week; take 1g of polyvinyl alcohol ( PVA) was put into the above system, and the stirring was continued for 24 hours to obtain a PVA-intercalated montmorillonite solution, which was macroscopically transparent and uniform, and the system was stable. Dip the polymethylethylene carbonate film with a thickness of 40um into the montmorillonite solution intercalated with PVA, take it out and put it in 80 oC After drying in an oven for 10 minutes, a biodegradable high-barrier plastic film material is obtained, and the thickness of the coating layer is 1.2um. The results of oxygen transmission rate and water vapor transmission rate are shown in Table 1.

Embodiment 2

[0042] Put 1.5 g of montmorillonite organically modified by quaternary ammonium salts into 100 ml of deionized water, ultrasonicate for 2 hours, the ultrasonic frequency is 60KHz, seal the system and stir vigorously at a speed of 160rpm for one week; take 1g of polyvinyl alcohol ( PVA) was put into the above system, and the stirring was continued for 24 hours to obtain a PVA-intercalated montmorillonite solution, which was macroscopically transparent and uniform, and the system was stable. Dip the 200um thick polymethylethylene carbonate film into the montmorillonite solution intercalated with PVA, take it out and put it in 80 o C drying in an oven for 10 minutes to obtain a biodegradable high-barrier plastic film material, the thickness of the coating layer is 1.25um. The results of oxygen transmission rate and water vapor transmission rate are shown in Table 1.

Embodiment 3

[0044]Put 1.0 g of hydrotalcite organically modified by sodium lauryl sulfate into 100 ml of deionized water, ultrasonicate for 2 hours at an ultrasonic frequency of 40KHz, seal the system and stir vigorously at a speed of 130rpm for one week; take 1 g poly Put vinyl alcohol (PVA) into the above system and continue to stir for 24 hours to obtain a PVA-intercalated hydrotalcite solution. The solution is macroscopically transparent and uniform, and the system is stable. Dip the polymethylethylene carbonate film with a thickness of 500um into the PVA-intercalated hydrotalcite solution, take it out and put it in 80 o C drying in an oven for 10 minutes to obtain a biodegradable high-barrier plastic film material, the thickness of the coating layer is 1.15um. The results of oxygen transmission rate and water vapor transmission rate are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com