A kind of nano mesoporous material/surfactant type composite antistatic agent and its preparation method and application

A technology of nano-mesoporous materials and composite antistatic agents, which is applied in the preparation of test samples, etc., can solve the problems of reducing the heat-resistant temperature and surface characteristics of materials, the environmental humidity that is not resistant to scrubbing, and the negative impact of the environment. Order migration, excellent antistatic performance, and strong slow-release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Preparation of surfactant-type antistatic agent solution

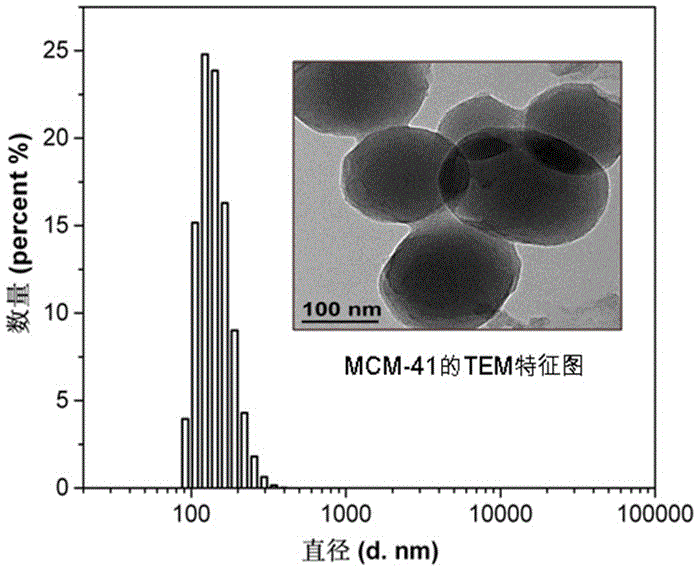

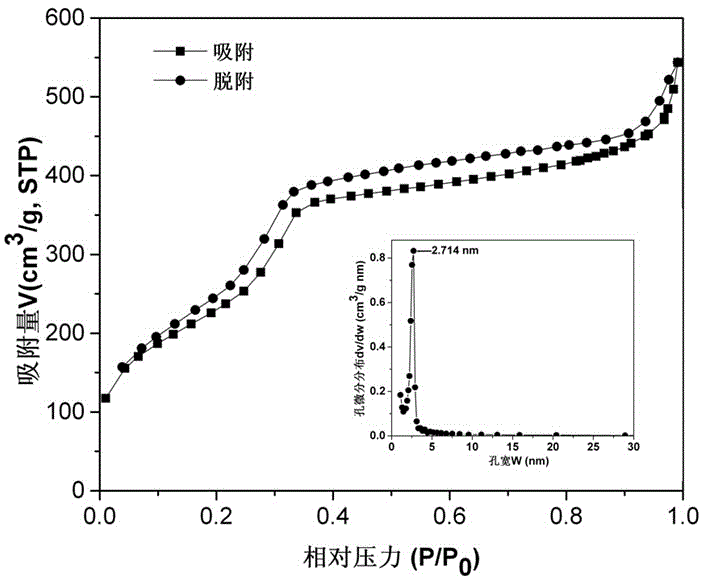

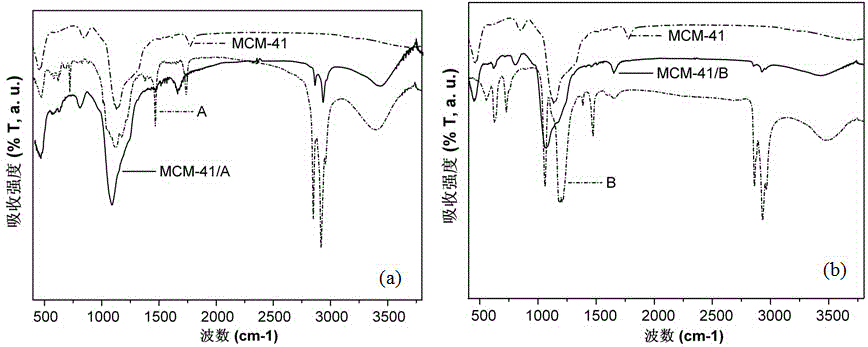

[0044] The nano mesoporous material MCM-41 (its morphology and pore size distribution are as follows figure 1 and figure 2 Shown;) 1.0g, surfactant type antistatic agent A (infrared characteristic spectrum as image 3 As shown in (a), the physical characteristics are shown in Table 1 and Figure 4 As shown in (a), 2.0 g were put into the vacuum drying phase, and dried at a constant temperature of 60°C for 48 hours. Dissolve 1.0 g of the dried surfactant-type antistatic agent in 60 ml of organic solvent ethanol, ultrasonicate for 120 minutes in an ultrasonic disperser, operating frequency 60KHZ, power 150W, temperature 25°C, and then continue stirring and dissolving the mixed solution for 2 hours , to obtain surfactant antistatic agent organic solution;

[0045] Table 1 Physical characteristics of the nano-mesoporous loaded surfactant-type antistatic agent synthesized in Example 1

[0046]

[0047] (...

Embodiment 2

[0051] (1) Preparation of surfactant-type antistatic agent solution

[0052] Put 1.0 g of nano-mesoporous material MCM-22 and 2.0 g of surfactant antistatic agent A into the vacuum drying phase respectively, and dry at a constant temperature of 60°C for 48 hours. Dissolve 2.0 g of the dried surfactant-type antistatic agent in 60 ml of organic solvent ethanol, ultrasonicate for 120 minutes in an ultrasonic disperser, operating frequency 60KHZ, power 150W, temperature 25°C, and then continue stirring and dissolving the mixed solution for 2 hours , to obtain surfactant antistatic agent organic solution;

[0053] (2) Preparation of compound antistatic agent by MCM-22 / surfactant type antistatic agent

[0054] Add 1.0g of dried MCM-22 to the organic solution of the above-mentioned surfactant type antistatic agent, sonicate in the ultrasonic disperser for 120 minutes, the working frequency is 60KHZ, the power is 150W, and the temperature is 25°C, and then the mixed solution is conti...

Embodiment 3

[0056] (1) Preparation of surfactant-type antistatic agent solution

[0057] Put 1.0 g of nanometer mesoporous material MCM-48 and 2.0 g of surfactant antistatic agent A into the vacuum drying phase respectively, and dry at a constant temperature of 60°C for 48 hours. Dissolve 2.0 g of the dried surfactant-type antistatic agent in 60 ml of organic solvent ethanol, ultrasonicate for 120 minutes in an ultrasonic disperser, operating frequency 60KHZ, power 150W, temperature 25°C, and then continue stirring and dissolving the mixed solution for 2 hours , to obtain surfactant antistatic agent organic solution;

[0058] (2) Preparation of compound antistatic agent by MCM-48 / surfactant type antistatic agent

[0059] Add 1.0g of dried MCM-48 to the organic solution of the above-mentioned surfactant type antistatic agent, and ultrasonicate for 120 minutes in an ultrasonic disperser with a working frequency of 60KHZ, a power of 150W, and a temperature of 25°C, and then continue stirrin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com