Floating junction silicon carbide SBD device with block-shaped groove and buried layer

A silicon carbide and trench technology, applied in the field of microelectronics, can solve the problems of small forward conduction current of the device, low duty cycle of the conduction channel, and reduction of device breakdown voltage, etc., and achieve large forward conduction current , large breakdown voltage and short switching time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

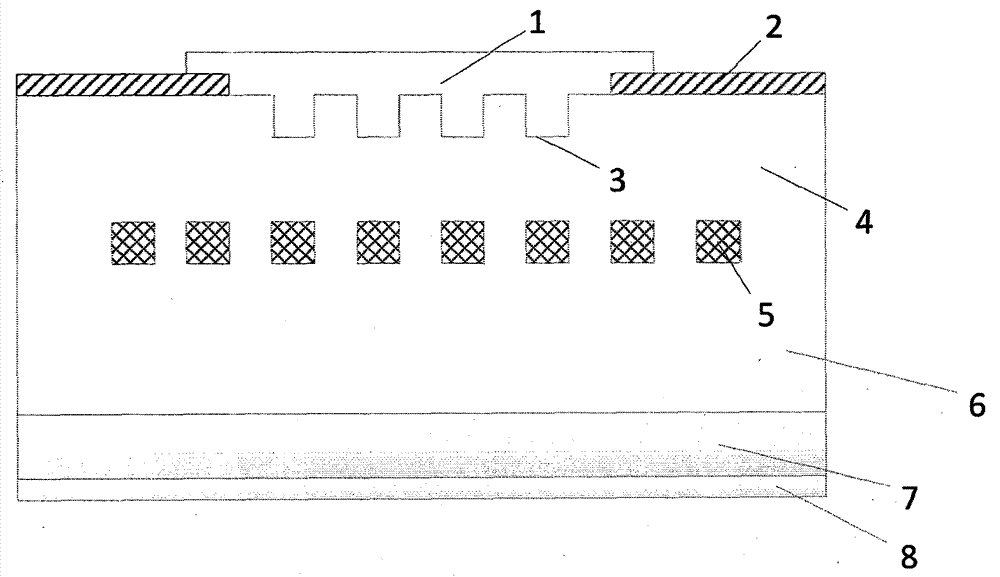

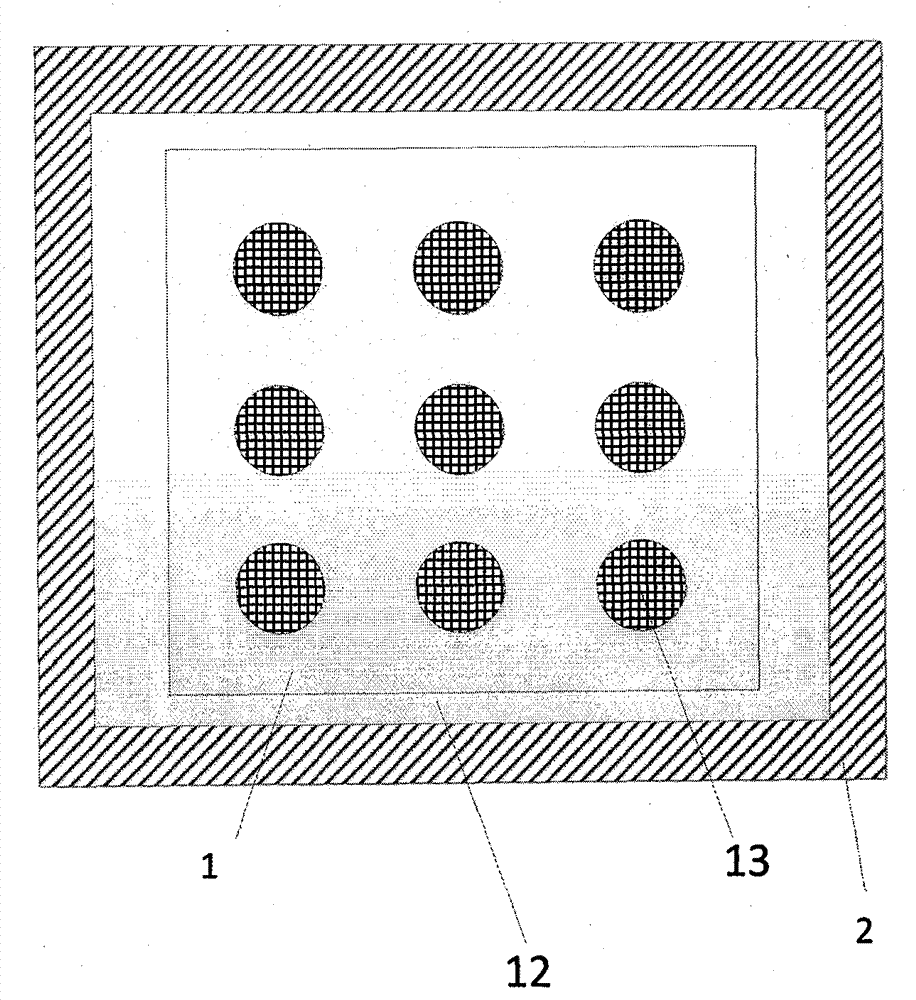

[0046] refer to Figure 1a and Figure 1b , the structure of the trench type floating junction silicon carbide SBD device with circular or hexagonal and elliptical block buried layers in the present invention is as follows:

[0047] N + The substrate is an N-type SiC substrate, and the primary N - The epitaxial layer is located at N + on the substrate, P + The ion-implanted region is located once N - epitaxial layer surface, secondary N - The epitaxial layer is located once N - above the epitaxial layer.

[0048] Metal and SiO 2 The isolation medium is located at the secondary N - Above the epitaxial layer, metal and SiO 2 The isolation dielectric is adjacent, and the metal and SiO 2 There are phase overlaps in the isolation media. The trench is located under the metal, the quadratic N - surface of the epitaxial layer.

[0049] Once N - The thickness of the epitaxial layer is 5 μm, and the doping concentration of nitrogen ions is 1×10 16 cm -3 . P + The dopin...

Embodiment 2

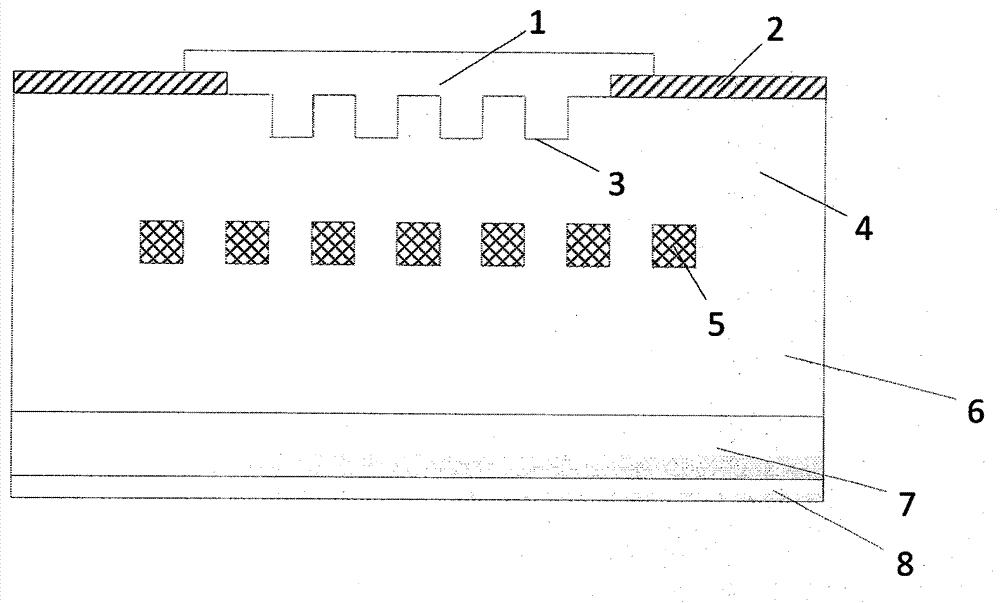

[0053] refer to Figure 1a and Figure 5 , the structure of the trench type floating junction silicon carbide SBD device with circular or hexagonal and elliptical or massive buried layers in the present invention is as follows:

[0054] N + The substrate is an N-type SiC substrate, and the primary N - The epitaxial layer is located at N + on the substrate, P + The ion-implanted region is located once N - epitaxial layer surface, secondary N - The epitaxial layer is located once N - above the epitaxial layer.

[0055] Metal and SiO 2 The isolation medium is located at the secondary N - above the epitaxial layer. Metal and SiO 2 The isolation dielectric is adjacent, and the metal and SiO 2 There are phase overlaps in the isolation media. The trench is located under the metal, the quadratic N - surface of the epitaxial layer.

[0056] Once N - The thickness of the epitaxial layer is 10 μm, and the doping concentration of nitrogen ions is 5×10 15 cm -3 . P + The...

Embodiment 3

[0060] refer to figure 2 and Figure 8 , the structure of the trench type floating junction silicon carbide SBD device with circular or hexagonal and elliptical block buried layers in the present invention is as follows:

[0061] N + The substrate is an N-type SiC substrate, and the primary N - The epitaxial layer is located at N + on the substrate, P + The ion-implanted region is located once N - epitaxial layer surface, secondary N - The epitaxial layer is located once N - above the epitaxial layer.

[0062] Metal and SiO 2 The isolation medium is located at the secondary N - above the epitaxial layer. Metal and SiO 2 The isolation dielectric is adjacent, and the metal and SiO 2 There are phase overlaps in the isolation media. The trench is located under the metal, the quadratic N - surface of the epitaxial layer.

[0063] Once N - The thickness of the epitaxial layer is 5 μm, and the doping concentration of nitrogen ions is 3×10 15 cm -3 . P + The dopin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com