Transparent back plate for solar cell module

A technology of solar cells and components, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as high product cost and backplane delamination, and achieve the effects of lower backplane cost, high light transmittance, and excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

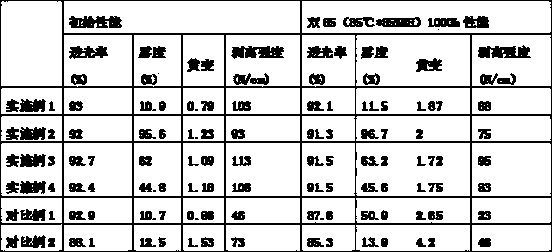

Examples

Embodiment 1

[0022] The coating formula of the weather-resistant layer is as follows (parts by mass):

[0023] Fluorine-containing resin GK570 (Dakin Paint) 100;

[0024] Modified resin 4701 (Dow Chemical) 20;

[0025] Curing agent TPA-90SB (Asahi Kasei, Japan) 10;

[0026] Curing accelerator Dibutyltin dilaurate 0.5;

[0027] UV absorber BYK3812 (German BYK Chemicals) 1;

[0028] Solvent ethyl acetate 10.

[0029] The coating formulation of the adhesive layer is as follows (parts by mass):

[0030] Acrylic resin LR7765 (Mitsubishi, Japan) 100;

[0031] Modified resin 4701 (Dow Chemical) 30;

[0032] Curing agent TPA-90SB (Asahi Kasei, Japan) 10;

[0033] Curing accelerator Dibutyltin dilaurate 2;

[0034] UV absorber BYK3812 (German BYK chemical) 2;

[0035] Solvent ethyl acetate 20.

[0036] The process of making the back sheet: select a transparent PET film with a thickness of 250 μm, and use a corona device to corona to 50~60dyne / cm. First, coat the surface layer of PET a...

Embodiment 2

[0039] The coating formula of the weather-resistant layer is as follows (parts by mass):

[0040] Fluorine-containing resin GK570 (Dakin Paint) 100;

[0041] Modified resin ST5790 (Toyobo, Japan) 50;

[0042] Curing agent N3390 (Bayer, Germany) 20;

[0043] Curing accelerator Dibutyltin dilaurate 1;

[0044] Anti-hydrolysis stabilizer P200 (Rheinland Stabaxol series) 0.5;

[0045] UV absorber / light stabilizer UV-531 / UV-292 2 / 2;

[0046] Matting powder C803 (made in Grace, USA) 10;

[0047] Solvent propylene glycol methyl ether acetate 100.

[0048] The coating formulation of the adhesive layer is as follows (parts by mass):

[0049] Acrylic resin ACR6730 (Gaoming Tongde Chemical) 100;

[0050] Modified resin ST5790 (Toyobo, Japan) 50;

[0051] Curing agent N3390 (Bayer, Germany) 15;

[0052] Curing accelerator Dibutyltin dilaurate 1;

[0053] UV absorber / light stabilizer UV-531 / UV-292 2 / 2;

[0054] Solvent butyl acetate 40.

[0055] The process of making the bac...

Embodiment 3

[0058] The coating formula of the weather-resistant layer is as follows (parts by mass):

[0059] Fluorine-containing resin GK570 (Dakin Paint) 100;

[0060] Modified resin GK680 (Toyobo, Japan) 100;

[0061] Curing agent Desmodur Z4470 (Bayer, Germany) 30;

[0062]Curing accelerator dibutyltin dilaurate 2;

[0064] Matting powder C803 (American Grace) 20;

[0065] Anti-hydrolysis stabilizer P200 (Rheinland Stabaxol series) 2;

[0066] UV absorber / light stabilizer UV-196 / UV-292 4 / 4;

[0067] Solvent Xylene / Propylene Glycol Methyl Ether Acetate 100 / 150.

[0068] The coating formulation of the adhesive layer is as follows (parts by mass):

[0069] Acrylic resin LR7765 (Mitsubishi, Japan) 100;

[0070] Modified resin GK680 (Japan Toyo Textile) 100;

[0071] Curing agent Desmodur Z4470 (Bayer, Germany) 25;

[0072] Curing accelerator dibutyltin dilaurate 2;

[0073] Matting powder C803 (American Grace) 20;

[0074] UV absorber / light stabiliz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com