A lithium-air battery based on graphene oxide-carbon paper gas catalytic electrode

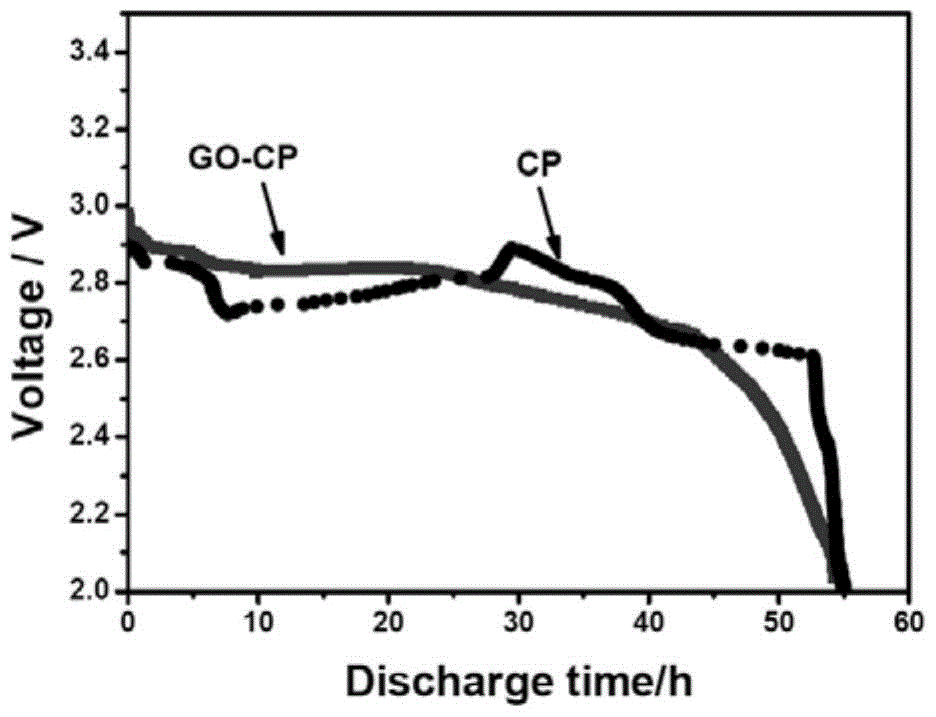

A gas catalytic electrode and air battery technology, which is applied to battery electrodes, fuel cell half-cells, secondary battery-type half-cells, circuits, etc., can solve the problem of electrode conductivity damage, oxygen transmission channel blockage, and charging failure. and other problems, to achieve the effect of large discharge capacity, improved stability, and reduced ohmic voltage drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

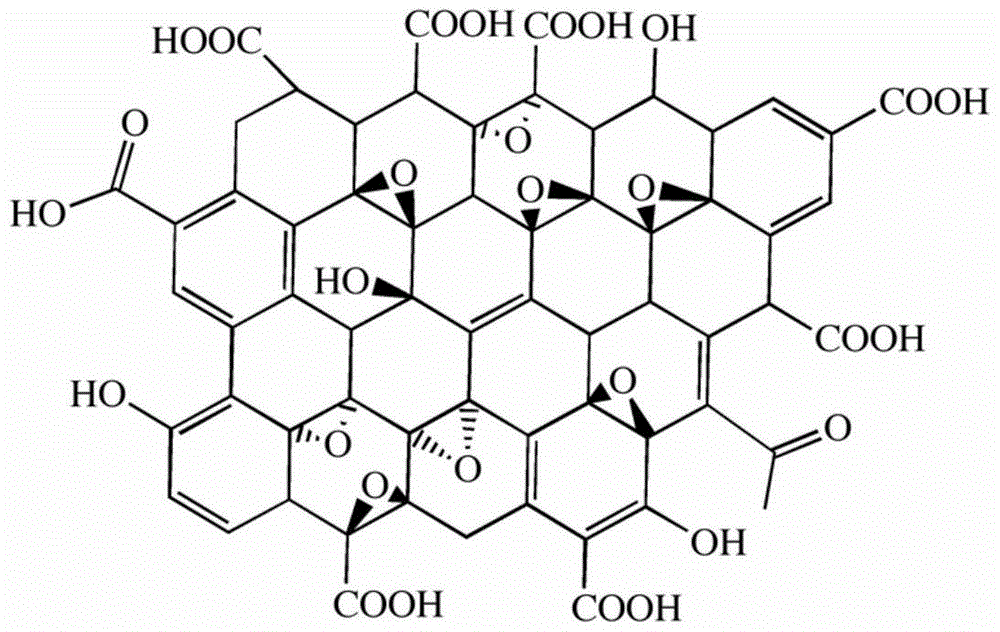

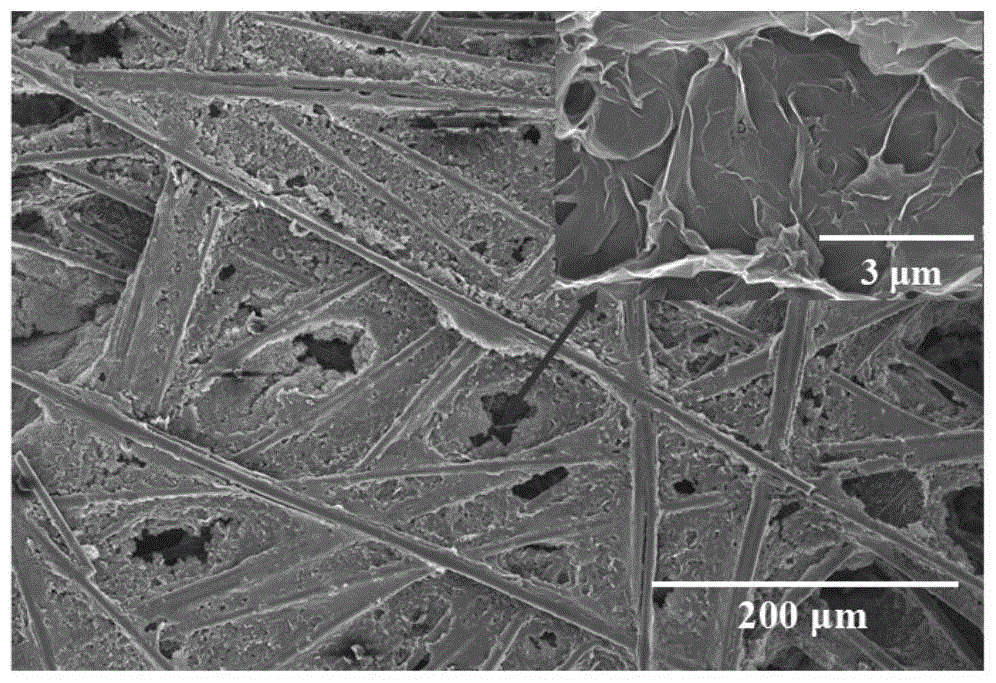

[0033] Graphene oxide at 1.0mg / cm 3 The concentration of ultrasonic dispersion in double distilled water, adding KH 2 PO 4 and K 2 HPO 4 , prepared into a phosphate buffer solution with pH 9.0, and continued to ultrasonically disperse for 6 hours to make it into a uniformly dispersed suspension. The electrophoresis-electrolytic cell is assembled with a platinum electrode as the negative electrode and carbon paper as the positive electrode. The voltage of the electrolytic cell is controlled at 20V by the stabilized power supply, and the temperature of the electrolyte is controlled at 45°C. The surface is evenly attached and deposited, using a uniform stirring device, the stirring rate is 2000r / min, and the electrolysis reaction time is 5min. The carbon paper electrode loaded with graphene oxide was cleaned with twice distilled water, and its Raman spectrum is shown in the attached Figure 6 . The cleaned carbon paper electrodes loaded with graphene oxide were baked in a v...

Embodiment 2

[0035] Graphene oxide at 2.0mg / cm 3 The concentration of ultrasonic dispersion in double distilled water, adding KH 2 PO 4 and K 2 HPO 4 , prepared into a phosphate buffer solution with a pH of 8.0, and continued ultrasonic dispersion for 6 hours to form a uniformly dispersed suspension. The electrophoresis-electrolytic cell is assembled with a platinum electrode as the negative electrode and carbon paper as the positive electrode. The voltage of the electrolytic cell is controlled at 15V by the stabilized power supply, and the temperature of the electrolyte is controlled at 35°C. During the electrolysis process, in order to make the graphene oxide on the carbon paper The surface is uniformly attached and deposited, using a uniform stirring device, the stirring rate is 3000r / min, and the electrolysis reaction time is 15min. The carbon paper electrode loaded with graphene oxide was cleaned with double distilled water, and the cleaned carbon paper electrode loaded with graph...

Embodiment 3

[0038] Graphene oxide at 3.0mg / cm 3 The concentration of ultrasonic dispersion in double distilled water, adding KH 2 PO 4 and K 2 HPO 4 , prepared into a phosphate buffer solution with pH 7.0, and continued to ultrasonically disperse for 6 hours to make it into a uniformly dispersed suspension. The electrophoresis-electrolytic cell is assembled with a platinum electrode as the negative electrode and carbon paper as the positive electrode. The voltage of the electrolytic cell is controlled at 8V by the stabilized power supply, and the temperature of the electrolyte is controlled at 25°C. During the electrolysis process, in order to make the graphene oxide on the carbon paper The surface is uniformly attached and deposited, using a uniform stirring device, the stirring rate is 4000r / min, and the electrolysis reaction time is 25min. The carbon paper electrode loaded with graphene oxide was cleaned with double distilled water, and the cleaned carbon paper electrode loaded wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com