DBD (Dielectric Barrier Discharge) low temperature plasma generating device and polymer film surface treatment method

A low-temperature plasma, polymer film technology, applied in the direction of plasma, electrical components, etc., can solve the problems of low processing efficiency, poor processing effect, plasma non-uniformity, etc., to improve the processing capacity and processing efficiency, increase the number of and area, water contact angle reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

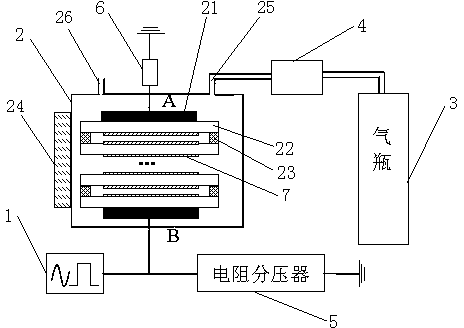

[0038] Such as figure 1 As shown, the DBD low-temperature plasma generating device includes a power source 1 and a DBD plasma reactor 2 .

[0039] The reaction chamber of the DBD plasma reactor 2 is provided with two metal electrodes 21: a metal electrode A and a metal electrode B, and at least three layers of dielectric plates 22 are arranged between the two metal electrodes 21, and between adjacent dielectric plates 22 It has a gap of 0.5mm-3mm, which is the gas gap during discharge treatment, hereinafter referred to as "air gap". In the same DBD low-temperature plasma generation device, the width of these gaps can be all equal or unequal; metal electrodes A is grounded, and the metal electrode B is connected to the high-voltage output end of the power source 1 .

[0040] The two metal electrodes 21 can be either parallel plate electrodes or cylindrical electrodes, as long as the two opposite end surfaces of the two metal electrodes 21 are parallel to each other.

[0041] ...

Embodiment 2

[0044] On the basis of Embodiment 1, in this embodiment, spacers 23 are used to separate adjacent dielectric plates 22, so that a gap is formed between adjacent dielectric plates 22, and the height of the spacers 23 is the width of the gap. Generally, the dielectric board 22 is in a rectangular shape. In this embodiment, four spacers 23 are respectively arranged on the four corners of the adjacent dielectric boards 22 . In this embodiment, the dielectric plates 22 are separated by the spacers 23 to provide a discharge air gap between the dielectric plates 22, which is very convenient, and the removal and installation of the dielectric plates 22 are also more convenient.

Embodiment 3

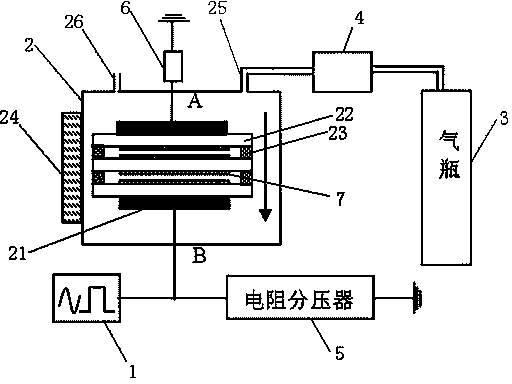

[0046] On the basis of Embodiment 1 or Embodiment 2, in this embodiment, the DBD low-temperature plasma generating device further includes a gas cylinder 3 , a resistor divider 5 and a sampling resistor 6 .

[0047] The reaction chamber of the DBD plasma reactor 2 is provided with an air inlet 25, an air outlet 26 and an observation window 24: the air outlet 26 is used to evacuate the reaction chamber and discharge unnecessary gases; To pass into the reaction gas, it is connected to the gas cylinder 3 through the air inlet pipeline, and a flow meter 4 is also arranged on the air inlet pipeline between the air inlet 25 and the gas cylinder 3, in order to change and select the gas flow rate; the observation window 24 is used It is used for observing plasma discharge and diagnosing plasma characteristics. In practical applications, the number of flowmeters, gas cylinders, and gas types can be set as required.

[0048] The input terminal of the resistance divider 5 is connected b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com