A kind of preparation method of cubic phase aluminum nitride fiber

A technology of phase aluminum nitride and fiber, applied in the direction of chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., to achieve the effect of simple and feasible process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] In a vacuum glove box, weigh 0.01mol of anhydrous aluminum chloride and 0.09mol of tetrabutylammonium azide and dissolve them in 40g of xylene to form a solution with a total mass fraction of solute of 40%, and then add 0.02mol of polyethylene glycol Diol 20000, stirred until completely dissolved to obtain a mixed solution. The mixed solution was transferred to a high-temperature reaction kettle, kept in an oven at 240° C. for 24 h, and cooled naturally to room temperature. The product in the reaction kettle was taken out, washed with xylene, and centrifuged, and repeated three times. The precipitate was collected and dried at 80°C. The dried product was calcined at 800° C. for 4 hours in a vacuum atmosphere, and then taken out and calcined at 500° C. for 4 hours in an air atmosphere to obtain cubic aluminum nitride fibers.

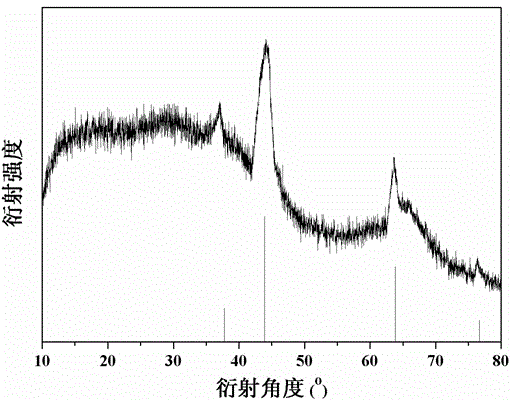

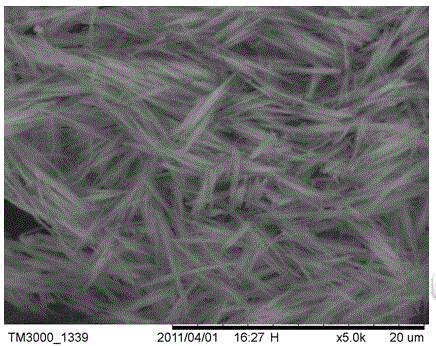

[0017] XRD test result shows, this product is the cubic aluminum nitride of pure phase (see figure 1 ), the SEM photo shows that the product is ...

Embodiment 2

[0019] In a vacuum glove box, weigh 0.01 mol of anhydrous aluminum chloride and 0.09 mol of tetrabutylammonium azide and dissolve them in 18 g of xylene to form a solution with a total mass fraction of solute of 60%, and then add 0.05 mol of hexadecane Alkyltrimethylammonium bromide, stirred until completely dissolved to obtain a mixed solution. The mixed solution was transferred to a high-temperature reaction kettle, kept in an oven at 280° C. for 12 hours, and naturally cooled to room temperature. The product in the reactor was taken out, washed with xylene, centrifuged, and repeated 5 times, and the precipitate was collected and dried at 100°C. The dried product was calcined at 1000° C. for 1 h under the protection of nitrogen, and then taken out and calcined at 700° C. for 1 h under air atmosphere to obtain cubic phase aluminum nitride fibers.

Embodiment 3

[0021] In a vacuum glove box, weigh 0.01 mol of anhydrous aluminum chloride and 0.09 mol of tetrabutylammonium azide and dissolve them in 27 g of xylene to form a solution with a total mass fraction of solute of 50%, and then add 0.04 mol of dodecyl ammonium Alkyl sodium sulfate, stirred until completely dissolved to obtain a mixed solution. The mixed solution was transferred to a high-temperature reaction kettle, kept in an oven at 260° C. for 18 h, and naturally cooled to room temperature. The product in the reaction kettle was taken out, washed with xylene, and centrifuged, and repeated 4 times. The precipitate was collected and dried at 90°C. The dried product was calcined at 900° C. for 2 hours in a vacuum atmosphere, and then taken out and calcined at 600° C. for 2 hours in an air atmosphere to obtain cubic aluminum nitride fibers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com