A kind of nanocomposite material and its preparation method and application

A nano-composite material and reaction technology, applied in the field of nano-composite materials and its preparation, can solve the problems of uncontrolled size and shape of particle size, high decomposition temperature of oxidant, slow decomposition process, etc. The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

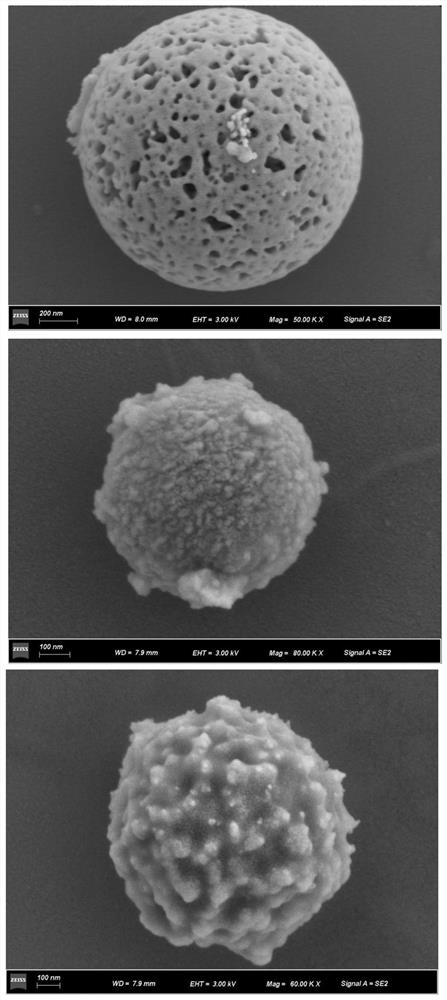

Image

Examples

preparation example Construction

[0042] The present invention provides a PN / Cu / CoCuP 2 O 7 The preparation method of nanocomposite material comprises the following steps:

[0043] The black phosphorene dispersion liquid, copper salt and cobalt salt are mixed and then heated and reacted to obtain a reaction product;

[0044] The reaction product is calcined under a protective atmosphere to obtain a nanocomposite material.

[0045] In the present invention, the preparation method of the black phosphorene dispersion comprises the following steps:

[0046] The black phosphorus crystal is refined into powder and then prepared into a black phosphorus dispersion;

[0047] Ultrasound, centrifugation and freeze-drying are carried out on the black phosphorus dispersion to obtain black phosphorus;

[0048] The black phosphorene dispersion is obtained by mixing the black phosphorene, the alcohol solvent and the glycerol.

[0049]In the present invention, the black phosphorus crystal powder is preferably dispersed in...

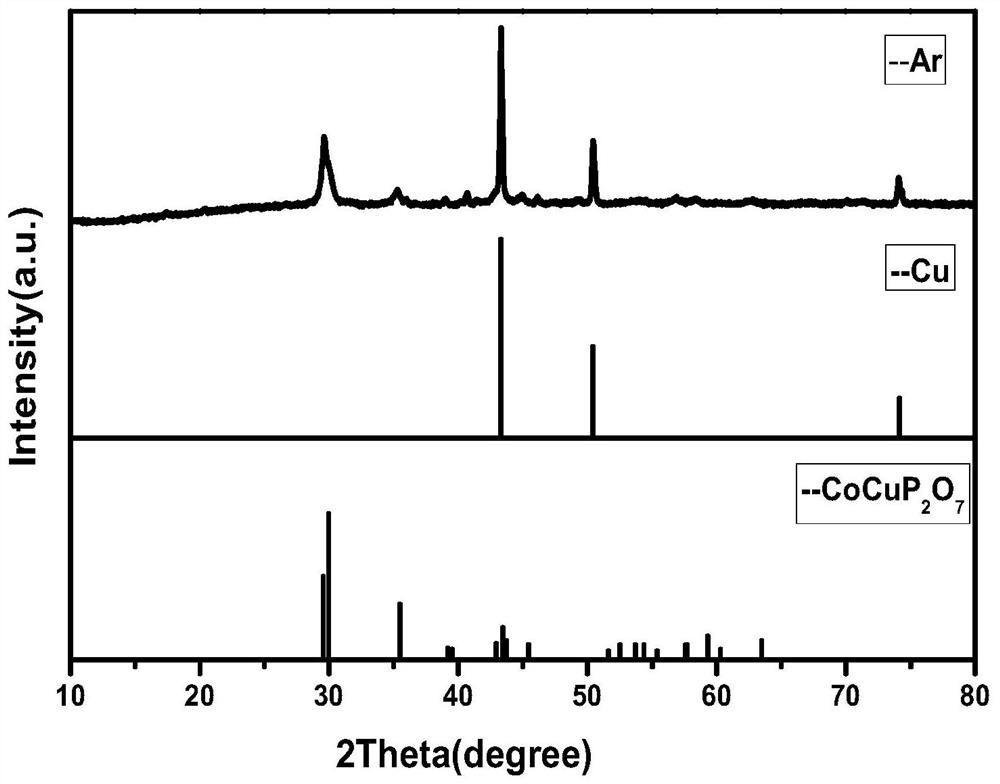

Embodiment 1

[0066] 1. Purge and grind the black phosphorus crystals with argon gas in a mortar to powder with metallic luster, transfer the black phosphorus powder to a beaker filled with argon gas, add an appropriate amount of water to the beaker, and the concentration is 1mg / ml of black phosphorus dispersion. Put the beaker in an ice bath and put it into the cell disruptor. Under the argon atmosphere, the bottom of the sample is about 2cm away from the ultrasonic probe, the ultrasonic power is 45%, and the ultrasonic is turned on for 2s and off for 4s for 8h, and then at 7000r Centrifugation for 10 min at a speed of / min, and then freeze-drying at -50 °C for 3 h to obtain black phosphorene;

[0067] 2. Ultrasonic disperse 80mg black phosphorene obtained in step 1 in 40ml isopropanol, ultrasonic power 95%, time 30 minutes; then add 8ml glycerol to the isopropanol dispersion of black phosphorene, 250rpm / min The black phosphorene dispersion is obtained by mechanical stirring for 1 hour, a...

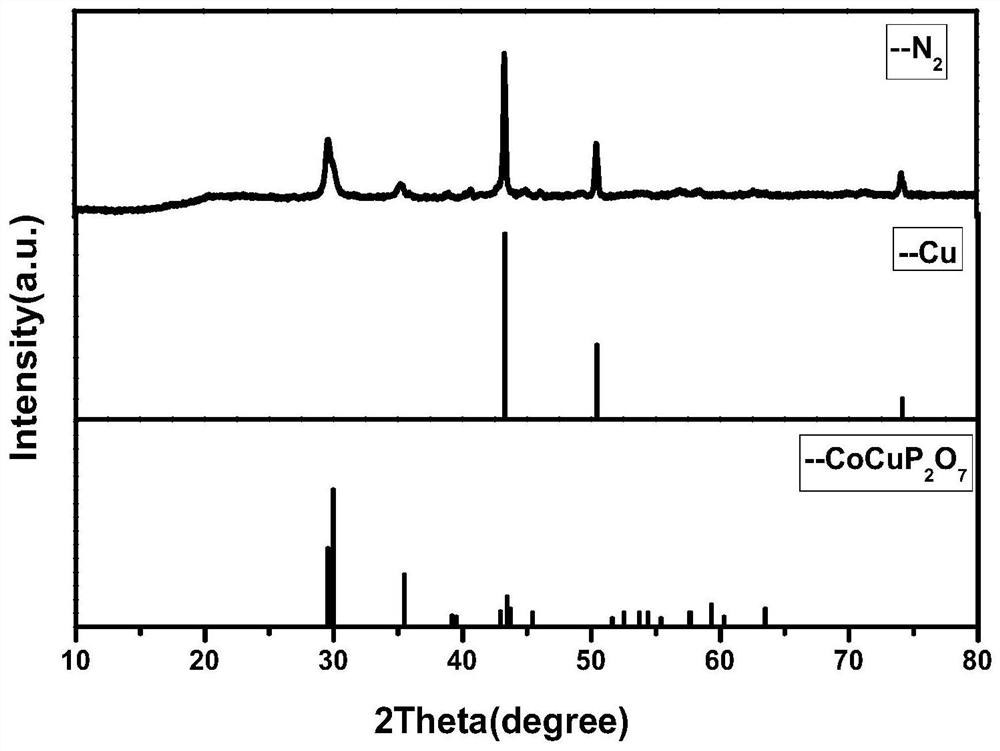

Embodiment 2

[0071] 1. Purge and grind the black phosphorus crystals with argon in a mortar to a powder with metallic luster, transfer the black phosphorus powder to a beaker filled with nitrogen, add an appropriate amount of water to the beaker, and prepare a concentration of 1 mg / ml. Black phosphorus dispersion. Put the beaker in an ice bath, put it into the cell disrupter, under nitrogen atmosphere, the bottom of the sample is about 2cm away from the ultrasonic probe, the ultrasonic power is 50%, and the ultrasonic is turned on for 2s and off for 4s for 8h, and then at 6000r / Centrifuge for 10 min at a speed of 1 min, and then freeze-dried at -30 °C for 4 h to obtain black phosphorene;

[0072] 2. Ultrasonic disperse 70mg black phosphorene obtained in step 1 in 40ml methanol, ultrasonic power 90%, time 30 minutes; then add 8ml glycerol to the isopropanol dispersion of black phosphorene, stir mechanically at 250rpm / min Treat for 1 hour to obtain black phosphorene dispersion, and the who...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com