Granular microbial agent and production method thereof

A microbial bacterial agent and granular technology, which is applied in the field of granular microbial bacterial agent and its production, can solve the problem of no breakthrough in strain screening, domestication fermentation technology, strain compatibility and other technical aspects, lagging development of popularization and application work, and limited products Use and effect and other issues to achieve the effect of ensuring the number of effective viable bacteria, inhibiting the reproduction of harmful bacteria, and improving the quality of agricultural products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

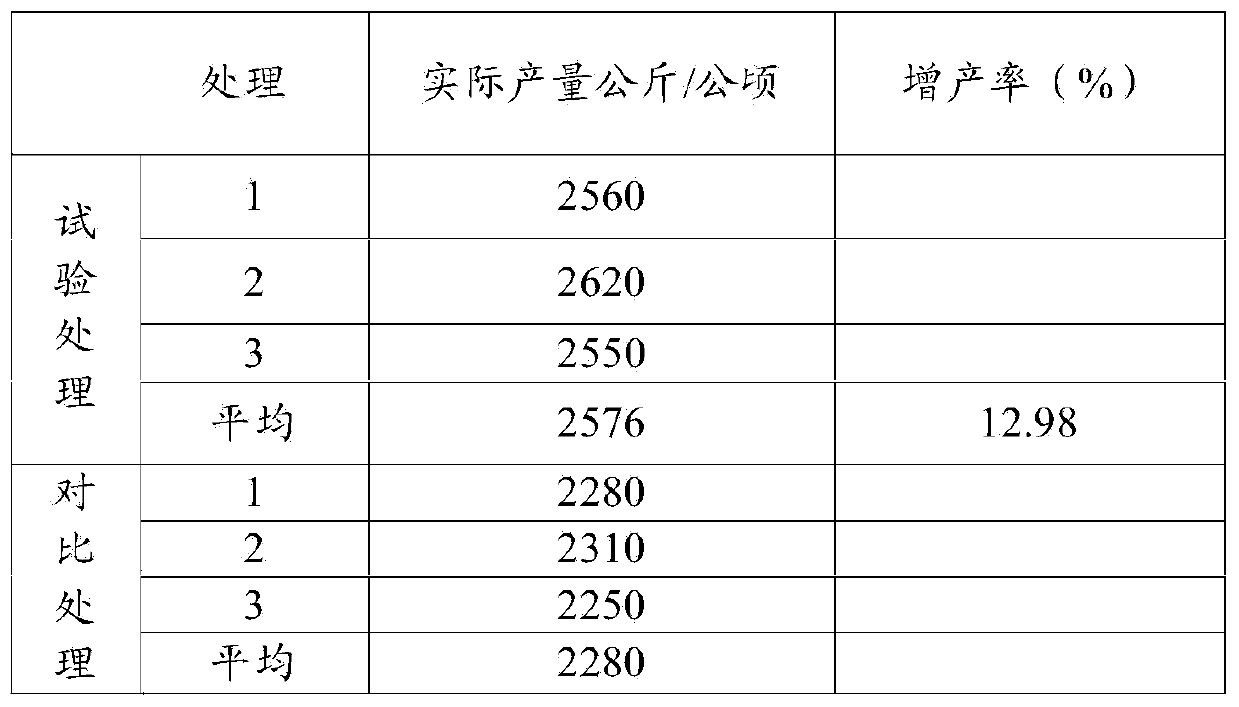

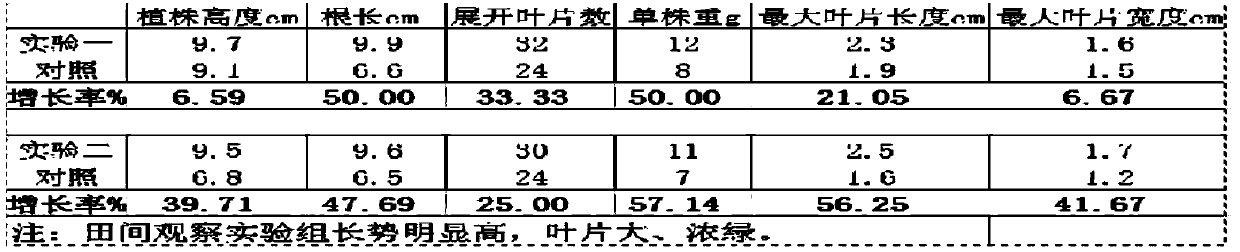

Examples

Embodiment 1

[0035] A granular microbial inoculant, the main effective components of which are by weight:

[0036] 70 parts of iron ore tailings, 5 parts of 2wt% chitosan aqueous solution, 2 parts of molasses, 15 parts of clay, and 3 parts of formula bacteria; the formula bacteria include Bacillus cereus, Bacillus megaterium, Bacillus subtilis, and Bacillus licheniformis Bacillus, lactic acid bacteria and Streptomyces flavinus, the mass ratio is: 30:15:12:20:11:12.

[0037] The Bacillus cereus strain number described therein is CMCC63305, the Bacillus megaterium strain number is ACCC01667, the Bacillus subtilis strain number is ACCC10242, the Bacillus licheniformis strain number is ACCC19372, the lactic acid bacteria strain number is CICC22703, fine yellow Streptomyces strain number is CICC11006;

[0038] The weight percent of main components in the described iron ore tailings slag is: CaO5.5%, MgO1.5%, SO 3 0.4%, SiO 2 5.2%, FeO8.1%, MnO0.06%, K 2 O0.11%, pulverized to more than 100 m...

Embodiment 2

[0044] A granular microbial inoculant, the main effective components of which are by weight:

[0045] 80 parts of iron ore tailings, 10 parts of 2wt% chitosan aqueous solution, 5 parts of molasses, 10 parts of clay, and 5 parts of formula bacteria; the formula bacteria include Bacillus cereus, Bacillus megaterium, Bacillus subtilis, and Bacillus licheniformis Bacillus, lactic acid bacteria and Streptomyces flavinus, the mass ratio is: 25:10:10:25:7:15.

[0046] The Bacillus cereus strain number described therein is CMCC63305, the Bacillus megaterium strain number is ACCC01667, the Bacillus subtilis strain number is ACCC10242, the Bacillus licheniformis strain number is ACCC19372, the lactic acid bacteria strain number is CICC22703, fine yellow Streptomyces strain number is CICC11006;

[0047] The weight percent of the main components in the iron ore tailings slag is: CaO4.1%, MgO1.3%, SO 3 0.2%, SiO 2 6.4%, FeO7.2%, MnO0.08%, K 2 O0.09%, pulverized to more than 100 mesh fo...

Embodiment 3

[0053] A granular microbial inoculant, the main effective components of which are by weight:

[0054] 75 parts of iron ore tailings, 8 parts of 2wt% chitosan aqueous solution, 4 parts of molasses, 13 parts of clay, and 2 parts of formula bacteria; the formula bacteria include Bacillus cereus, Bacillus megaterium, Bacillus subtilis, and Bacillus licheniformis Bacillus, lactic acid bacteria and Streptomyces flavinus, the mass ratio is: 35:5:5:15:5:15.

[0055] The Bacillus cereus strain number described therein is CMCC63305, the Bacillus megaterium strain number is ACCC01667, the Bacillus subtilis strain number is ACCC10242, the Bacillus licheniformis strain number is ACCC19372, the lactic acid bacteria strain number is CICC22703, fine yellow Streptomyces strain number is CICC11006;

[0056] The weight percent of main components in the described iron ore tailings slag is: CaO5.2%, MgO1.8%, SO 3 0.48%, SiO 2 6.3%, FeO8.3%, MnO0.07%, K 2 O0.14%, pulverized to more than 100 mes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com