Preparation method of network polyaniline conducting active material

An active material, polyaniline technology, applied in the field of preparation of network-like polyaniline conductive active materials, can solve problems such as no literature reports, and achieve the effects of simple preparation process, uniform morphology and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

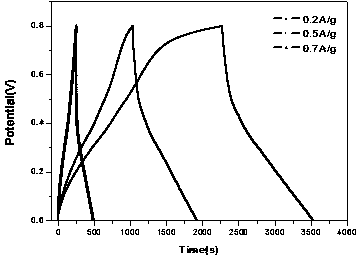

Image

Examples

Embodiment 1

[0019] (1) Ultrasonic disperse 0.5 ml of aniline in a beaker filled with 50 mL of deionized water, and ultrasonically disperse for 1 hour to make the dispersion uniform, and obtain an ultrasonic dispersion of aniline.

[0020] (2) Take phytic acid and join in the aniline ultrasonic dispersion prepared in step (1), after ultrasonic dispersion for 1 hour, the obtained aniline-phytic acid mixed solution is then moved to the prepared aniline-phytic acid mixed solution flask, and place the flask in an ice-water bath to lower the temperature of the aniline-phytic acid mixture to 3°C; the molar ratio of the weighed phytic acid to the amount of aniline in step (1) is 2:1.

[0021] (3) take ammonium persulfate and 5mL concentration and be 1 mol / liter hydrochloric acid solution, join in the beaker that fills 50mL deionized water, mix well, make mixed solution; 1) The molar ratio of the aniline consumption is 1.

[0022] (4) Add the mixed solution prepared in step (3) dropwise to the an...

Embodiment 2

[0024] (1) Ultrasonic disperse 0.5 ml of aniline in a beaker filled with 50 mL of deionized water, and ultrasonically disperse for 1 hour to make the dispersion uniform, and obtain an ultrasonic dispersion of aniline.

[0025] (2) Take phytic acid and join in the aniline ultrasonic dispersion prepared in step (1), after ultrasonic dispersion for 1 hour, the obtained aniline-phytic acid mixed solution is then moved to the prepared aniline-phytic acid mixed solution flask, and place the flask in an ice-water bath to lower the temperature of the aniline-phytic acid mixture to 3°C; the molar ratio of the weighed phytic acid to the amount of aniline in step (1) is 1:1.

[0026] (3) take ammonium persulfate and 5mL concentration and be 1 mol / liter hydrochloric acid solution, join in the beaker that fills 50mL deionized water, mix well, make mixed solution; 1) The molar ratio of the aniline consumption is 1.

[0027] (4) Add the mixed solution prepared in step (3) dropwise to the an...

Embodiment 3

[0029] (1) Ultrasonic disperse 0.5 ml of aniline in a beaker filled with 50 mL of deionized water, and ultrasonically disperse for 1 hour to make the dispersion uniform, and obtain an ultrasonic dispersion of aniline.

[0030] (2) Take phytic acid and join in the aniline ultrasonic dispersion prepared in step (1), after ultrasonic dispersion for 1 hour, the obtained aniline-phytic acid mixed solution is then moved to the prepared aniline-phytic acid mixed solution flask, and place the flask in an ice-water bath to lower the temperature of the aniline-phytic acid mixture to 3°C; the molar ratio of the weighed phytic acid to the amount of aniline in step (1) is 1:2.

[0031] (3) take ammonium persulfate and 5mL concentration and be 1 mol / liter hydrochloric acid solution, join in the beaker that fills 50mL deionized water, mix well, make mixed solution; 1) The molar ratio of the aniline consumption is 1.

[0032] (4) Add the mixed solution prepared in step (3) dropwise to the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com