Modified dolomite for heat-resistant flame-retardant fluoroplastic wire and cable material and preparation method of modified dolomite

A wire and cable and dolomite technology, applied in the field of modified dolomite and its preparation, can solve the problems of unsatisfactory mechanical properties of composite materials, difficult filling, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

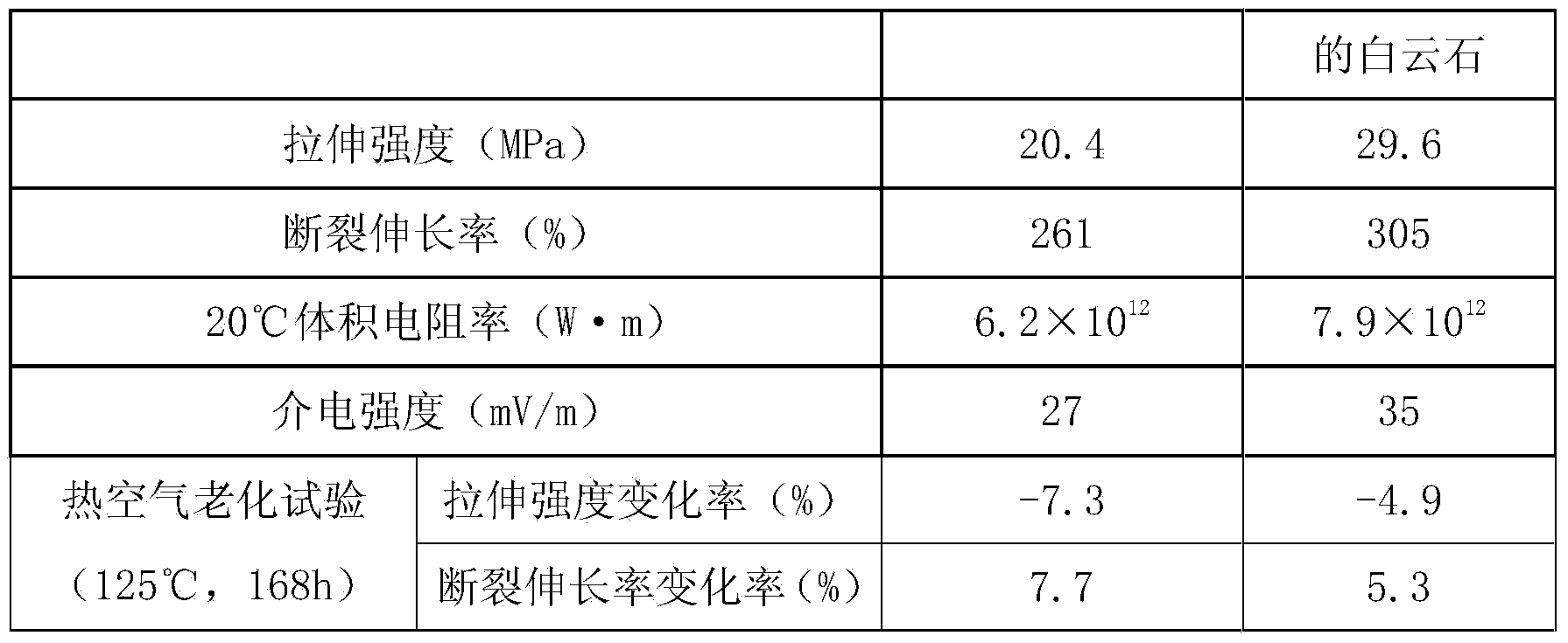

[0010] A modified dolomite for fluoroplastic heat-resistant and flame-retardant wire and cable materials, made of the following raw materials in weight (kg): 60 dolomite, 18 barium metatitanate, 22 BOVC resin, 12 pentabromobenzyl polyacrylate, Bisphenol A bis(diphenyl phosphate) 2.5, ceresin 4, niobium diselenide 3.5, diisodecyl phthalate 8, antimony tin oxide 3.5, silicon powder 10, p-aminophenol 1.5, 4- Vinylpyridine 0.8, vitamin C palmitate 1.5, additive 4;

[0011] The auxiliary agent is mixed by the following weight (kg) raw materials: 2-(2H-benzotriazol-2-yl) p-cresol 3, zinc isooctanoate 1, bis(2,4-di-tert-butyl phenyl) pentaerythritol diphosphite 2, tert-butyl hydroquinone 2.5, barium fluoride 5, p-methoxybenzoyl chloride 3, tantalum disulfide 6, vinyl ferrocene 3, glycerol trilaurate Ester 2.5, bis-ethylhexyloxyphenol methoxyphenyl triazine 2.

[0012] The preparation method of modified dolomite for heat-resistant and flame-retardant wire and cable materials of fluo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com