Additive of phenolic resin as well as preparation method and application of additive

A technology of phenolic resin and additives, which is applied in the field of phenolic resin additives, phenolic resin adhesives, phenolic resin additives for wood-based panels, and the preparation field. Reduce the period of time and other issues, to achieve the effect of reducing consumption, shortening the hot pressing time, and improving the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

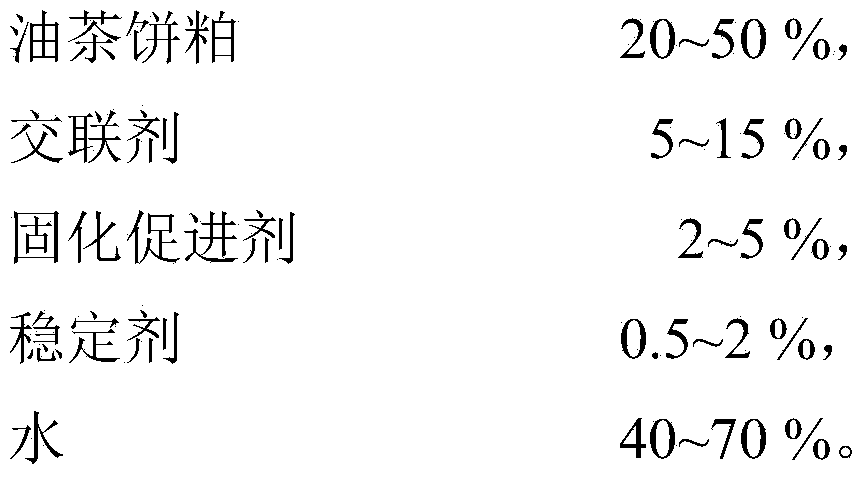

[0035] An additive for phenolic resin, based on the total mass of the additive as 100%, each component and mass percentage are as follows:

[0036]

[0037] A kind of preparation method of the additive of phenolic resin, described method concrete steps are as follows:

[0038] (1) Mix 10kg urea, 13kg formaldehyde and 0.5kg melamine evenly, add 0.1kg formic acid, stir evenly; heat to 85°C, keep warm until the viscosity of Tu 4 is 12 seconds, cool down to 70°C, add 30% sodium hydroxide solution , adjust the pH value to 7.5, react for 15 minutes, cool down to 30°C, and discharge to obtain a melamine-modified urea-formaldehyde resin prepolymer;

[0039] (2) Evenly disperse 50 kg of camellia oleifera cake powder in 40 kg of water, add 5 kg of melamine-modified urea-formaldehyde resin prepolymer and stir evenly to obtain mixture a; keep mixture a at 50° C. for 2 hours to obtain mixture b;

[0040] (3) Cool the mixture b to 30° C., add 4.5 kg of sodium carbonate and 0.5 kg of sod...

Embodiment 2

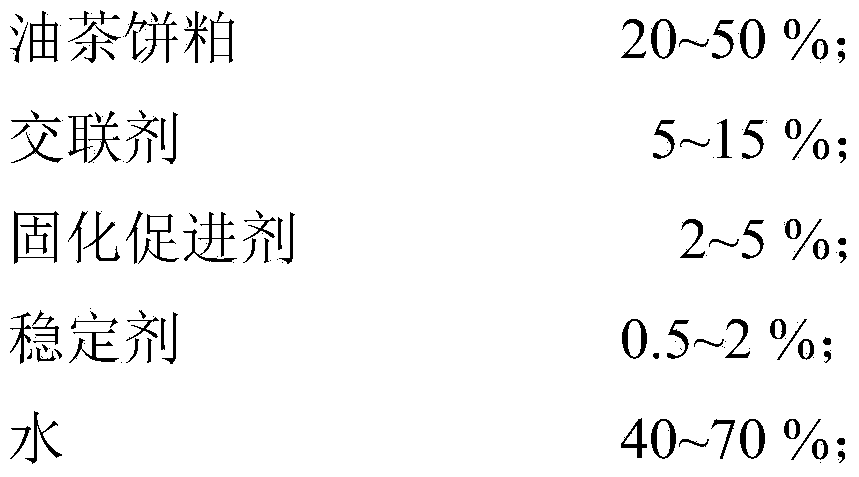

[0044] An additive for phenolic resin, based on the total mass of the additive as 100%, each component and mass percentage are as follows:

[0045]

[0046] A kind of preparation method of the additive of phenolic resin, described method concrete steps are as follows:

[0047] (1) Mix 10kg urea, 13kg formaldehyde and 0.5kg melamine evenly, add 0.1kg formic acid, stir evenly; heat to 85°C, keep warm until the viscosity of Tu 4 is 15 seconds, cool down to 70°C, add 30% sodium hydroxide solution , adjust the pH value to 7.5, react for 15 minutes, cool down to 30°C, and discharge to obtain a melamine-modified urea-formaldehyde resin prepolymer;

[0048] (2) Evenly disperse 20 kg of camellia oleifera cake powder in 58 kg of water, add 15 kg of melamine-modified urea-formaldehyde resin prepolymer and stir evenly to obtain mixture a; keep mixture a at 70° C. for 3 hours to obtain mixture b;

[0049] (3) Cool the mixture b to 30° C., add 5 kg of glycerol acetate and 2 kg of borax,...

Embodiment 3

[0053] An additive for phenolic resin, based on the total mass of the additive as 100%, each component and mass percentage are as follows:

[0054]

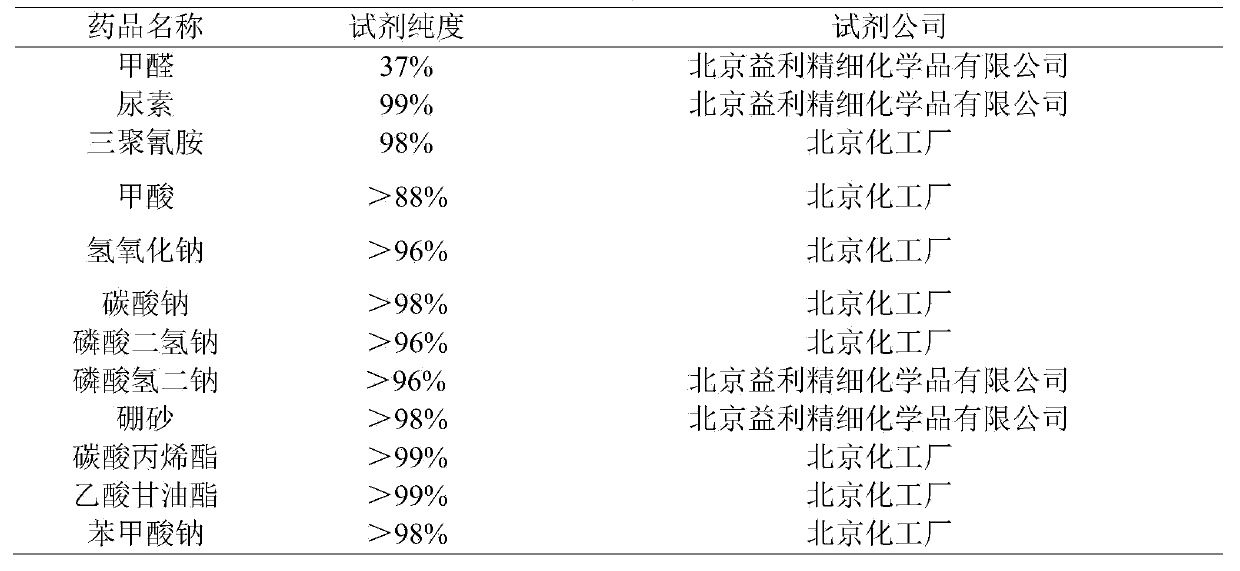

[0055]

[0056] A kind of preparation method of the additive of phenolic resin, described method concrete steps are as follows:

[0057] (1) Mix 10kg urea, 13kg formaldehyde and 0.5kg melamine evenly, add 0.1kg formic acid, stir evenly; heat to 85°C, keep warm until the viscosity of Tu 4 is 13 seconds, cool down to 70°C, add 30% sodium hydroxide solution , adjust the pH value to 7.5, react for 15 minutes, cool down to 30°C, and discharge to obtain a melamine-modified urea-formaldehyde resin prepolymer;

[0058] (2) Evenly disperse 20 kg of camellia oleifera cake powder in 70 kg of water, add 6 kg of melamine-modified urea-formaldehyde resin prepolymer and stir evenly to obtain mixture a; keep mixture a at 60° C. for 2.5 hours to obtain mixture b;

[0059] (3) Cool the mixture b to 30° C., add 3 kg of propylene carbonate and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com