Cold-proof and heat-insulated coating for outdoor tent and preparation method of cold-proof and heat-insulated coating

A technology for heat-insulating coatings and tents, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of poor cold-proof performance of coatings, and achieve excellent cold-proof and heat-insulation performance, abundant raw material sources, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

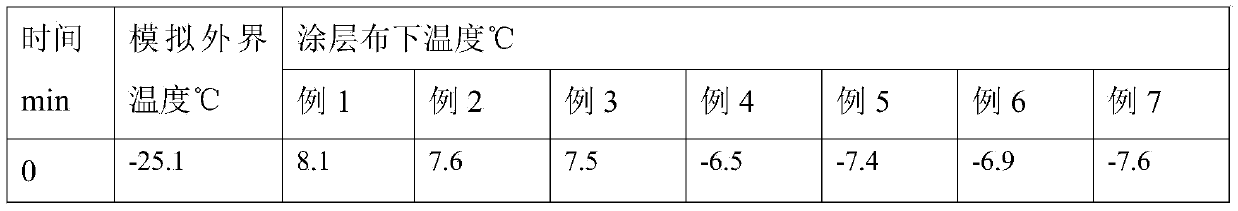

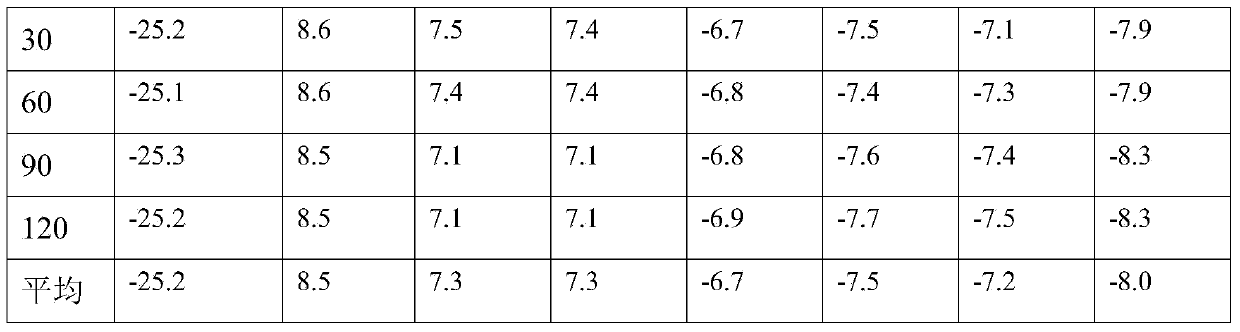

Examples

Embodiment 1

[0016] The cold-proof and heat-insulating coating for outdoor tents is made of the following components by weight: 50 parts of bisphenol A glycidyl ether, 10 parts of pigment, 1.5 parts of dispersant, 1.5 parts of leveling agent, 1.5 parts of preservative, and defoamer 1.5 parts, 1.5 parts of drier, 1.5 parts of plasticizer, 1.5 parts of film-forming aid, 30 parts of acetone, and 70 parts of water.

[0017] Among them, the pigment is titanium dioxide, the filler is calcium carbonate, the dispersant is a mixture of EFKA-5065 dispersant and EFKA-4050 dispersant according to 1:5; the leveling agent is EFKA-3777 leveling agent and EFKA-3239 leveling agent According to the mixture of 4:1; preservative is zinc phosphate; defoamer is mineral oil; drier is cobalt naphthenate; plasticizer is chlorinated paraffin; film-forming aid is 2,2,4-trimethyl 1,3-pentanediol monoisobutyrate.

[0018] Among them, the filler is expanded perlite, expanded vermiculite, diatomite and sepiolite with a...

Embodiment 2

[0021] The cold-proof and heat-insulating coating for outdoor tents is made of the following components by weight: 40 parts of bisphenol A glycidyl ether, 5 parts of pigment, 5 parts of filler, 1 part of dispersant, 2 parts of leveling agent, and 2 parts of preservative , 1 part of defoamer, 1 part of drier, 2 parts of plasticizer, 2 parts of film-forming aid, 30 parts of acetone, and 70 parts of water.

[0022] Among them, the pigment is titanium dioxide, the dispersant is a mixture of EFKA-5065 dispersant and EFKA-4050 dispersant according to 1:4; the leveling agent is EFKA-3777 leveling agent and EFKA-3239 leveling agent according to 5:1 The preservative is zinc powder; the defoamer is mineral oil; the drier is lead naphthenate; the plasticizer is phthalate diester; the film-forming aid is 2,2,4-trimethyl -1,3-Pentanediol monoisobutyrate.

[0023] Among them, the filler is expanded perlite, expanded vermiculite, diatomite and sepiolite with a mass ratio of 5:4:2:1.

[002...

Embodiment 3

[0026] The cold-proof and heat-insulating coating for outdoor tents is made of the following components by weight: 60 parts of bisphenol A glycidyl ether, 15 parts of pigment, 10 parts of filler, 2 parts of dispersant, 1 part of leveling agent, and 1 part of preservative , 2 parts of defoamer, 2 parts of drier, 1 part of plasticizer, 1 part of film-forming aid, 30 parts of acetone, and 70 parts of water.

[0027] Among them, the pigment is titanium dioxide, the dispersant is a mixture of EFKA-5065 dispersant and EFKA-4050 dispersant according to 1:6; the leveling agent is EFKA-3777 leveling agent and EFKA-3239 leveling agent according to 3:1 mixture; preservative is aluminum powder; defoamer is hydrophobic modified silica; drier is manganese naphthenate; plasticizer is chlorinated paraffin; film-forming aid is 2,2,4-trimethyl -1,3-Pentanediol monoisobutyrate.

[0028] Among them, the filler is expanded perlite, expanded vermiculite, diatomite and sepiolite with a mass ratio o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com