A cold-proof and heat-insulating tpu tent surface coating

A technology for surface coatings and tents, applied in the direction of anti-corrosion coatings, coatings, etc., can solve problems such as insufficient sunlight resistance, high temperature resistance, poor cold and heat insulation performance, general coating performance, etc., to improve cold and heat insulation performance, Excellent cold protection and heat insulation performance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

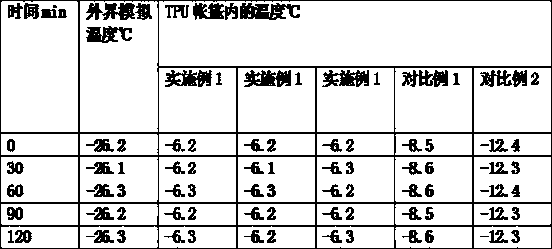

Examples

Embodiment 1

[0013] A cold-proof and heat-insulating TPU tent surface coating, which is made of the following components in parts by weight: n-butyl acrylate 15, rutile nano-titanium dioxide 3, modified sericite 1, methyl methacrylate 1, borax 2, synthetic Membrane aid 2, fatty acyl diethanolamine 10, hydroxypropyl cellulose 3, mussel mucin alcohol solution 1, deionized water 70; the mussel mucin alcohol solution is made of the following components in parts by weight: mussel mucin alcohol solution Mussel mucin 3, tapioca starch 1, diallylamine 0.4, ethylene glycol 40, the preparation method is: add mussel mucin to ethylene glycol according to the above parts by weight, after stirring evenly, add 0.2 parts by weight Diallylamine, heated to 40°C, stirred at 200r / min for 20min, then added tapioca starch and the remaining 0.2 parts by weight of diallylamine, continued to stir at 200r / min for 40min, then allowed to stand for natural cooling to room temperature, that is mussel mucin alcohol solu...

Embodiment 2

[0015] A cold-proof and heat-insulating TPU tent surface coating, which is made of the following components in parts by weight: n-butyl acrylate 18, rutile nano-titanium dioxide 6, modified sericite 3, methyl methacrylate 3, borax 5, synthetic Membrane aid 4, fatty acyl diethanolamine 12, hydroxypropyl cellulose 5, mussel mucin alcohol solution 3, deionized water 80; the mussel mucin alcohol solution is made of the following components in parts by weight: mussel mucin alcohol solution Mussel mucin 3, tapioca starch 1, diallylamine 0.4, ethylene glycol 40, the preparation method is: add mussel mucin to ethylene glycol according to the above parts by weight, after stirring evenly, add 0.2 parts by weight Diallylamine, heated to 40°C, stirred at 200r / min for 20min, then added tapioca starch and the remaining 0.2 parts by weight of diallylamine, continued to stir at 200r / min for 40min, then allowed to stand for natural cooling to room temperature, that is mussel mucin alcohol solu...

Embodiment 3

[0017] A cold-proof and heat-insulating TPU tent surface coating, which is made of the following components in parts by weight: n-butyl acrylate 17, rutile nano-titanium dioxide 4, modified sericite 2, methyl methacrylate 2, borax 3, synthetic Membrane aid 3, fatty acyl diethanolamine 11, hydroxypropyl cellulose 4, mussel mucin alcohol solution 2, deionized water 75; the mussel mucin alcohol solution is made of the following components by weight: mussel mucin alcohol solution Mussel mucin 3, tapioca starch 1, diallylamine 0.4, ethylene glycol 40, the preparation method is: add mussel mucin to ethylene glycol according to the above parts by weight, after stirring evenly, add 0.2 parts by weight Diallylamine, heated to 40°C, stirred at 200r / min for 20min, then added tapioca starch and the remaining 0.2 parts by weight of diallylamine, continued to stir at 200r / min for 40min, then allowed to stand for natural cooling to room temperature, that is mussel mucin alcohol solution.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com