A kind of fabric thermal insulation coating and preparation method thereof

A technology for thermal insulation coatings and fabrics, used in polyurea/polyurethane coatings, coatings, textiles and papermaking, etc., can solve the problem of low comprehensive performance, and achieve the effects of rich raw material sources, simple methods and excellent thermal insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

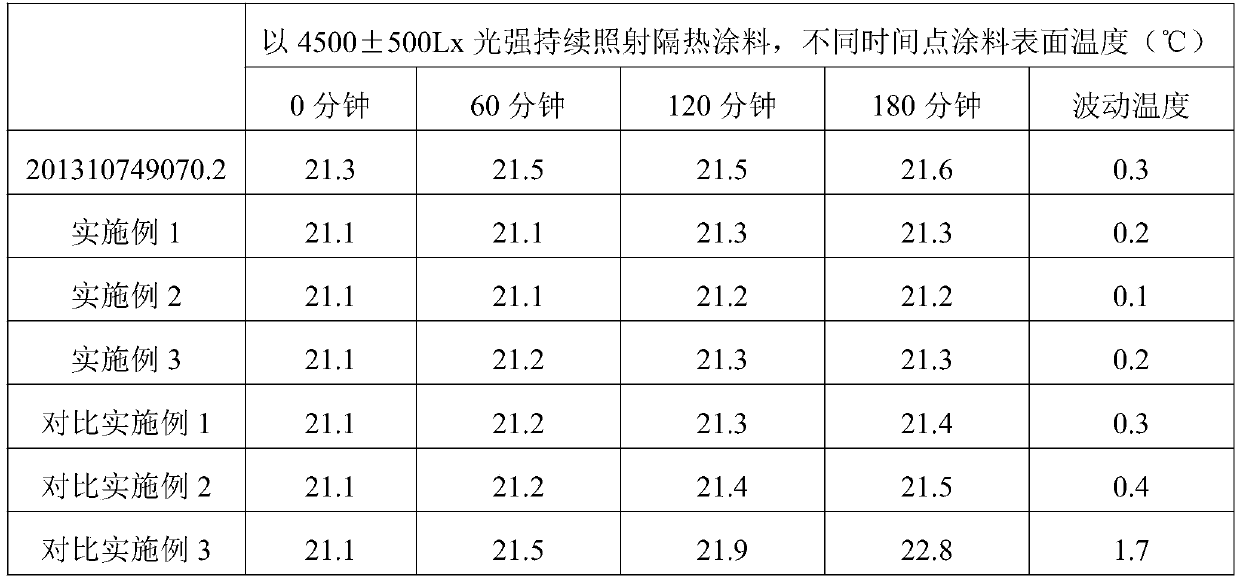

Examples

Embodiment 1

[0020] Raw material composition: ethanol 25%; 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate 0.3%; dioctyl phthalate 2%; phosphoric acid ester 0.6%; naphthenic acid 0.3% cobalt; 0.3% zinc phosphate; 20% porous oxide composite, 2% polyacrylic resin, and the rest is polyurethane; the porous oxide composite is a composite of titanium dioxide and silicon dioxide, and has uniformly distributed micropores , the mass ratio of titanium dioxide to silicon dioxide is 1:1.5, and the micropore diameter is 100-300nm.

[0021] The preparation steps of the porous oxide composite are as follows:

[0022] Step S1, take tetrabutyl titanate, absolute ethanol, distilled water, and glacial acetic acid at a molar ratio of 2:4:1:1.2, add tetrabutyl titanate to half the amount of absolute ethanol, and stir in an ice-water bath 5 minutes, then dropwise add the other half of absolute ethanol, distilled water and glacial acetic acid to form a mixed solution, and stir for 1 hour to obtain a transparent...

Embodiment 2

[0028] Raw material composition: ethanol 28%; 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate 0.7%; dioctyl phthalate 4%; phosphoric acid ester 0.9%; naphthenic acid 0.7% cobalt; 0.7% zinc phosphate; 25% porous oxide composite, 5% polyacrylic resin, and the rest is polyurethane; the porous oxide composite is a composite of titanium dioxide and silicon dioxide, and has uniformly distributed micropores , the mass ratio of titanium dioxide to silicon dioxide is 1:1.5, and the micropore diameter is 100-300nm.

[0029] The preparation steps of the porous oxide composite are as follows:

[0030] Step S1, take tetrabutyl titanate, absolute ethanol, distilled water, and glacial acetic acid at a molar ratio of 2:4:1:1.2, add tetrabutyl titanate to half the amount of absolute ethanol, and stir in an ice-water bath 5 minutes, then dropwise add the other half of absolute ethanol, distilled water and glacial acetic acid to form a mixed solution, and stir for 1 hour to obtain a transparent...

Embodiment 3

[0036] Raw material composition: ethanol 27%; 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate 0.5%; dioctyl phthalate 3%; phosphoric acid ester 0.8%; naphthenic acid 0.6% cobalt; 0.5% zinc phosphate; 23% porous oxide composite, 4% polyacrylic resin, and the rest is polyurethane; the porous oxide composite is a composite of titanium dioxide and silicon dioxide, and has uniformly distributed micropores , the mass ratio of titanium dioxide to silicon dioxide is 1:1.5, and the micropore diameter is 100-300nm.

[0037] The preparation steps of the porous oxide composite are as follows:

[0038] Step S1, take tetrabutyl titanate, absolute ethanol, distilled water, and glacial acetic acid at a molar ratio of 2:4:1:1.2, add tetrabutyl titanate to half the amount of absolute ethanol, and stir in an ice-water bath 5 minutes, then dropwise add the other half of absolute ethanol, distilled water and glacial acetic acid to form a mixed solution, and stir for 1 hour to obtain a transparent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com