Tempering heat treatment method of mn series high-strength finish-rolled threaded steel bar

A heat treatment method and technology for finishing threads, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of large tissue stress, high sensitivity to hydrogen embrittlement, and easy occurrence of brittle fracture, so as to achieve low production costs and reduce tissue stress. , to ensure the effect of strong toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

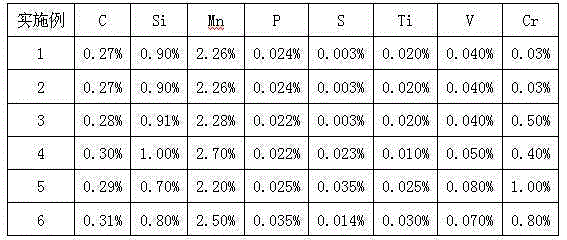

Examples

Embodiment 1

[0015] Embodiment 1: The tempering heat treatment method of the Mn-based high-strength finish-rolled threaded steel bar adopts the following specific process.

[0016] Put the steel into the heating furnace and heat it. After 3.5 hours of heating, the furnace temperature rises to 280°C; keep it in the heating furnace at 280°C for 6.0 hours; stop heating, and let the steel cool in the heating furnace until it cools down to At room temperature, the Mn-based high-strength finish-rolled rebar is obtained. The obtained high-strength finish-rolled threaded steel bar: tensile strength Rm=1214MPa, yield strength Rel=954MPa, elongation after fracture A=15%, total elongation under maximum force Agt=5.20%, meeting the PSB930 standard.

Embodiment 2

[0017] Embodiment 2: The tempering heat treatment method adopts the following specific processes.

[0018] Put the steel into the heating furnace for heating. After 4.0 hours of heating, the furnace temperature rises to 350°C; keep it in the heating furnace at 350°C for 6.0 hours; stop heating, and let the steel cool in the heating furnace until it cools down to At room temperature, Rm=1193MP, Rel=923MPa, A=15%, Agt=5.50%, Mn series high-strength finish-rolled rebar that meets PSB830 grade.

Embodiment 3

[0019] Embodiment 3: The tempering heat treatment method adopts the following specific processes.

[0020] Put the steel into the heating furnace for heating. After 3.0 hours of heating, the furnace temperature rises to 200°C; keep it in the heating furnace at 200°C for 5.0 hours; stop heating, and let the steel cool in the heating furnace until it cools down to At room temperature, Rm=1466MP, Rel=1125MPa, A=13%, Agt=4.50%, Mn series high-strength finish-rolled rebar that meets PSB1080 grade.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com