Waste incineration treatment system

A treatment system and waste incineration technology, applied in the field of waste incineration treatment systems, can solve the problems of immovability, limited use, and easy explosion, so as to improve treatment efficiency and quality, improve material combustion efficiency, and ensure complete combustion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

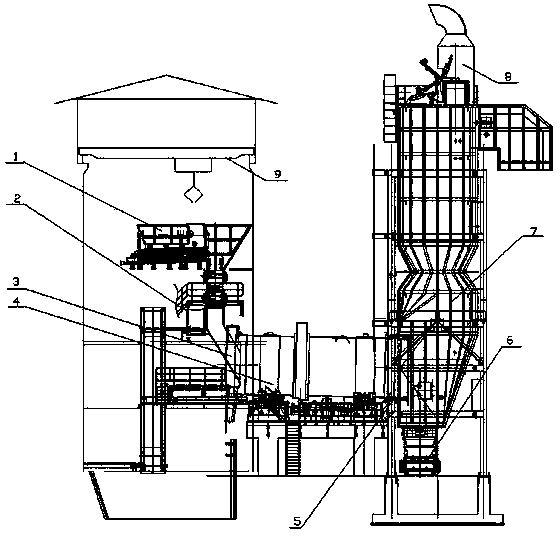

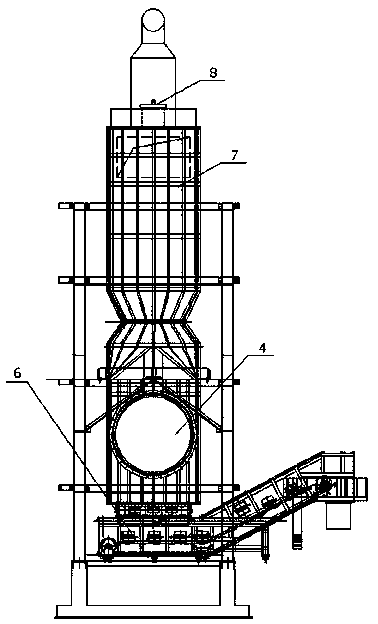

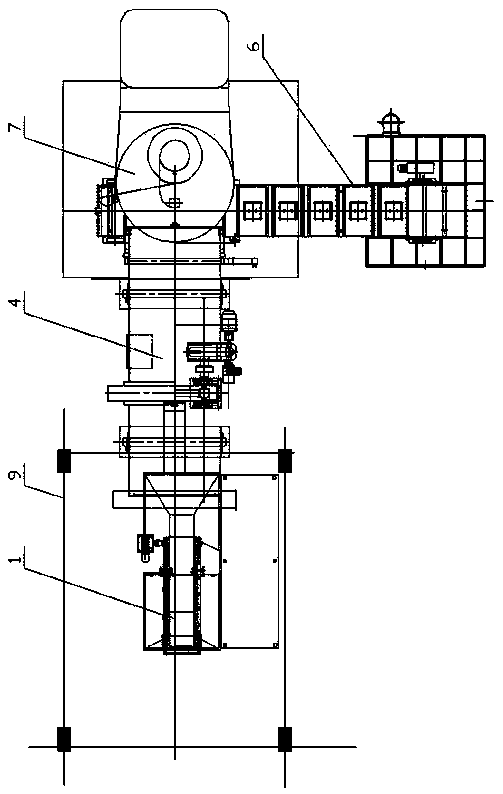

[0035] The present invention will be further described below in conjunction with the accompanying drawings.

[0036] See attached Figure 1-8 , The waste incineration treatment system disclosed in the present invention includes a lifting frame 9, a bulk material feeding device 1, a small package material conveying device 2, an incineration rotary kiln 4, a slag remover 6 and a secondary combustion chamber 7. The unsorted bulk garbage is fed by the bulk material feeding device, and the classified dangerous goods are pressed into small packages, which are fed by the small package material conveying device. The sprocket conveying mechanism sends out, and the flue gas produced by incineration is fully burned again in the second combustion chamber and then discharged.

[0037] The bulk material feeding device comprises an upper hopper 10, an apron conveyor 17 and an unloading passage, the apron conveyor is arranged below the upper hopper 10, and one side of the upper hopper 10 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com