Method for determining content of tin in tungsten concentrate

A technology for tungsten concentrate and content, applied in the field of laboratory analysis, can solve the problems of complex determination process of potassium iodate volumetric method, high test cost, inaccurate determination, etc., and achieve complete and complete separation of tungsten and tin, easy to popularize and use, and filter speed. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

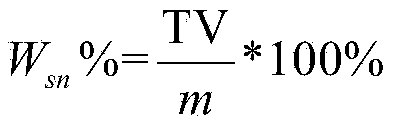

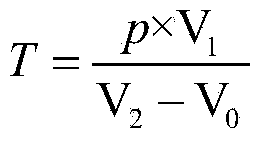

Examples

Embodiment 1

[0046] Samples to be tested: GSBD-45001-89 wolframite, XQ011301036 scheelite concentrate and XQ011301039 scheelite concentrate.

[0047] Preparation of compound melting agent: Take 20g of anhydrous borax, 10g of boric acid and 90g of zinc powder, grind them and mix them evenly.

[0048] Analysis steps:

[0049] Weigh 1.0000g sample (with the sample as reagent blank) and place it in a 10mL corundum crucible or porcelain crucible filled with 4g of mixed flux in advance, cover with 1g of mixed flux and 0.4g of potassium chloride (potassium chloride prevents metal liquid splashing), placed in an 800°C muffle furnace to melt for 20 minutes, taken out, and cooled. Use 50mL of 80°C hot hydrochloric acid with a concentration of 9mol / L to leaching the crucible completely, let the leaching solution cool down, and add 0.1g of potassium permanganate to oxidize the precipitate under low temperature conditions. Filter with fast filter paper, wash the beaker and funnel with dilute hydrochl...

Embodiment 2

[0066] Sample: GSBD-45001-89 Wolframite

[0067] Preparation of compound melting agent: take 23g of anhydrous borax, 13g of boric acid and 82g of zinc powder, grind them and mix them evenly.

[0068] Analysis steps:

[0069] Weigh 0.4000g sample (with the sample as reagent blank) and place it in a 10mL corundum crucible or porcelain crucible filled with 3g mixed flux in advance, cover with 0.5g mixed flux and 0.2g potassium chloride (when potassium chloride prevents high temperature dissolution metal liquid splashing), placed in a muffle furnace at 820°C for 22 minutes, taken out, and cooled. Use 30mL of 84°C hot hydrochloric acid with a concentration of 8.5mol / L to leaching the crucible completely, let the leaching solution cool down, and add 0.06g of potassium permanganate to oxidize the precipitate under low temperature conditions. Filter with fast filter paper, wash the beaker and funnel with dilute hydrochloric acid washing solution with a concentration of 2% by mass, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com