Method for preparing nonapeptide microspheres without sensitized auxiliary materials

A technology of sensitization and excipients, applied in the field of preparation of nonapeptide microspheres, to achieve the effects of increasing the range, reducing the frequency of medication, and improving the compliance and medication level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

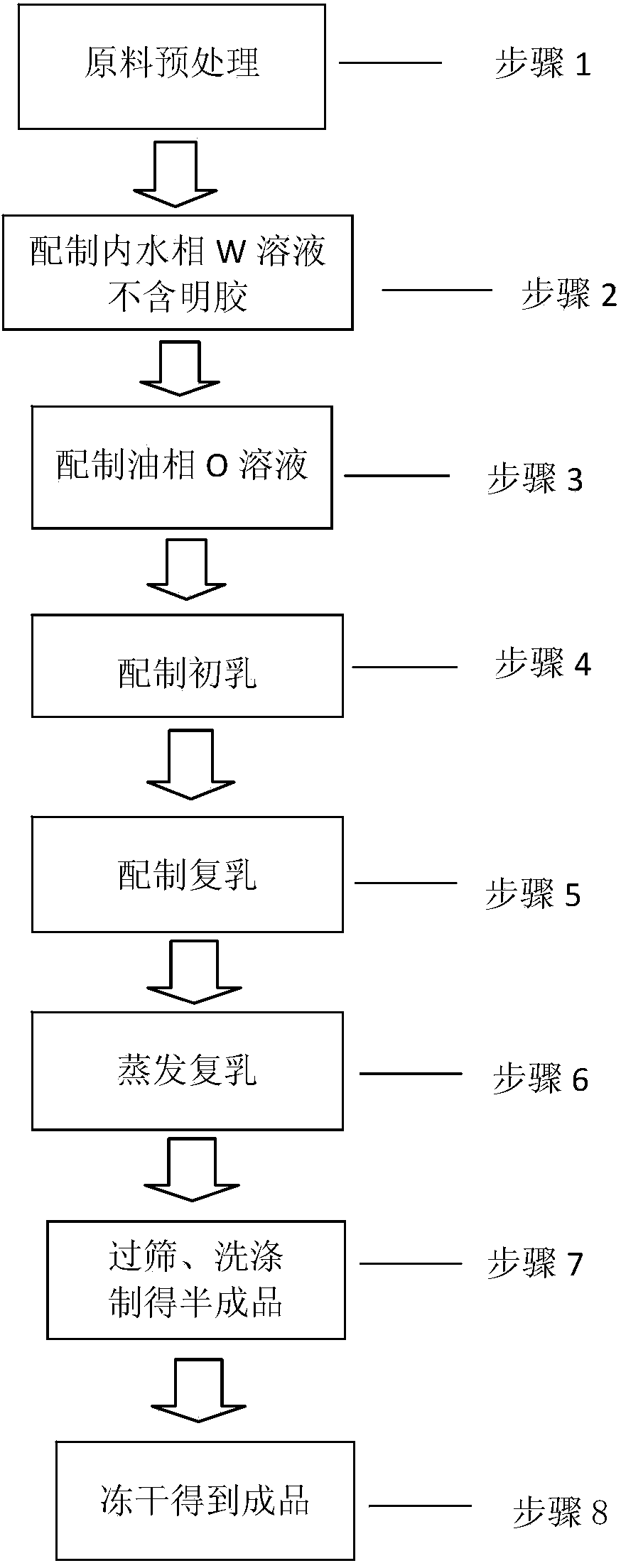

Method used

Image

Examples

Embodiment 1

[0038] Investigate the influence of the volume of the external water phase on the encapsulation of leuprolide acetate

[0039] Pretreatment of the raw material leuprolide acetate;

[0040] Put the pretreated 100 mg leuprolide acetate raw material into 300 mg of water and dissolve it as the inner water phase W solution, and the inner water phase W solution is not added with the allergenic auxiliary material gelatin;

[0041] Add 2.0g of lactic acid-glycolic acid polymer to 20g of methylene chloride as the oil phase O solution. The molecular weight of the lactic acid-glycolic acid polymer used is 12000-15000, the molar ratio of lactic acid to glycolic acid is 75:25, and lactic acid-ethanol The acid polymer is an acid end-blocking polymer;

[0042] The prepared inner water phase W solution and oil phase O solution are mixed, and the phacoemulsification method is adopted. The phacoemulsification method includes first-stage ultrasound and second-stage ultrasound. The first-stage ultrasonic...

Embodiment 2

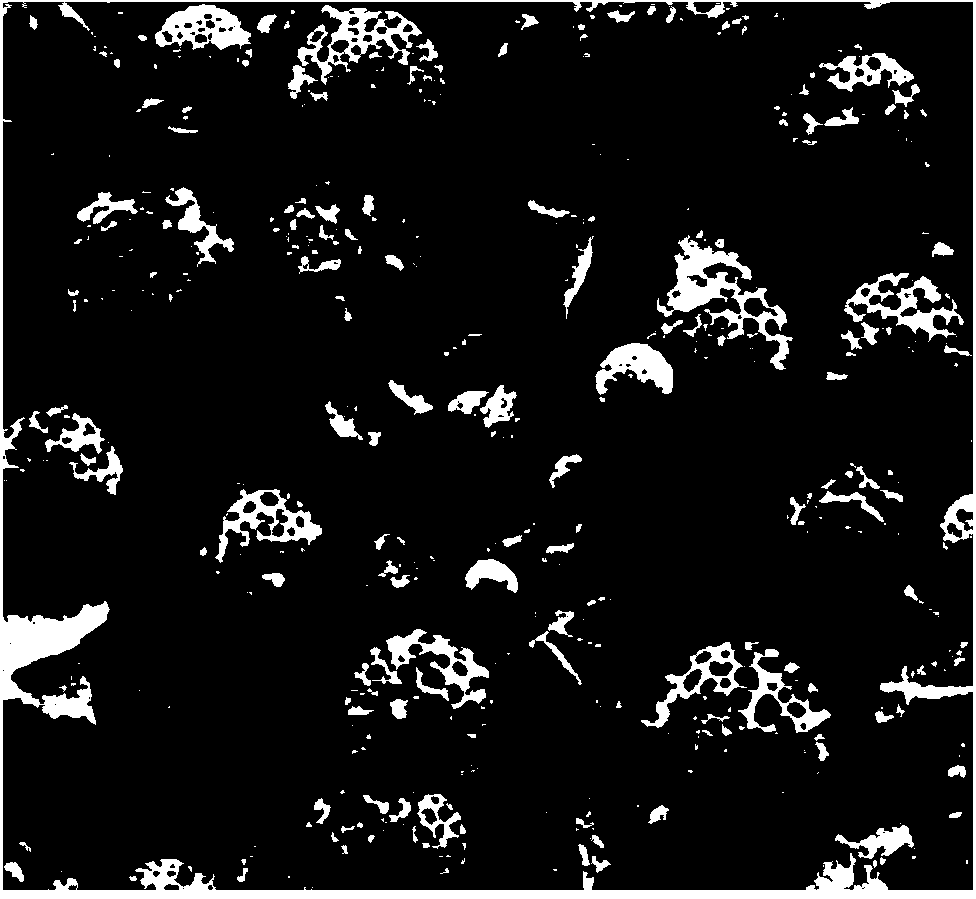

[0050] Investigate the effect of double emulsion temperature on the surface morphology of microspheres

[0051] Pretreatment of the raw material leuprolide acetate;

[0052] Put the 100 mg pretreated leuprolide acetate raw material into 300 mg of water and dissolve it as the inner aqueous phase W solution, and the inner aqueous phase W solution is not added with the allergenic auxiliary material gelatin;

[0053] Add 2.0 g of lactic acid-glycolic acid polymer to 20 g of dichloromethane as an oil phase O solution, the molecular weight of lactic acid-glycolic acid used is 12000-15000, the molar ratio is 75:25, and acidic end-capped polymer is selected;

[0054] The prepared inner water phase W solution and oil phase O solution are mixed, and the ultrasonic emulsification method is adopted. The ultrasonic power in the first stage is 10W, and the ultrasonic power in the second stage is 30W. Adjust the ultrasonic power to make the mixture become milky white, namely Get colostrum

[0055] Po...

Embodiment 3

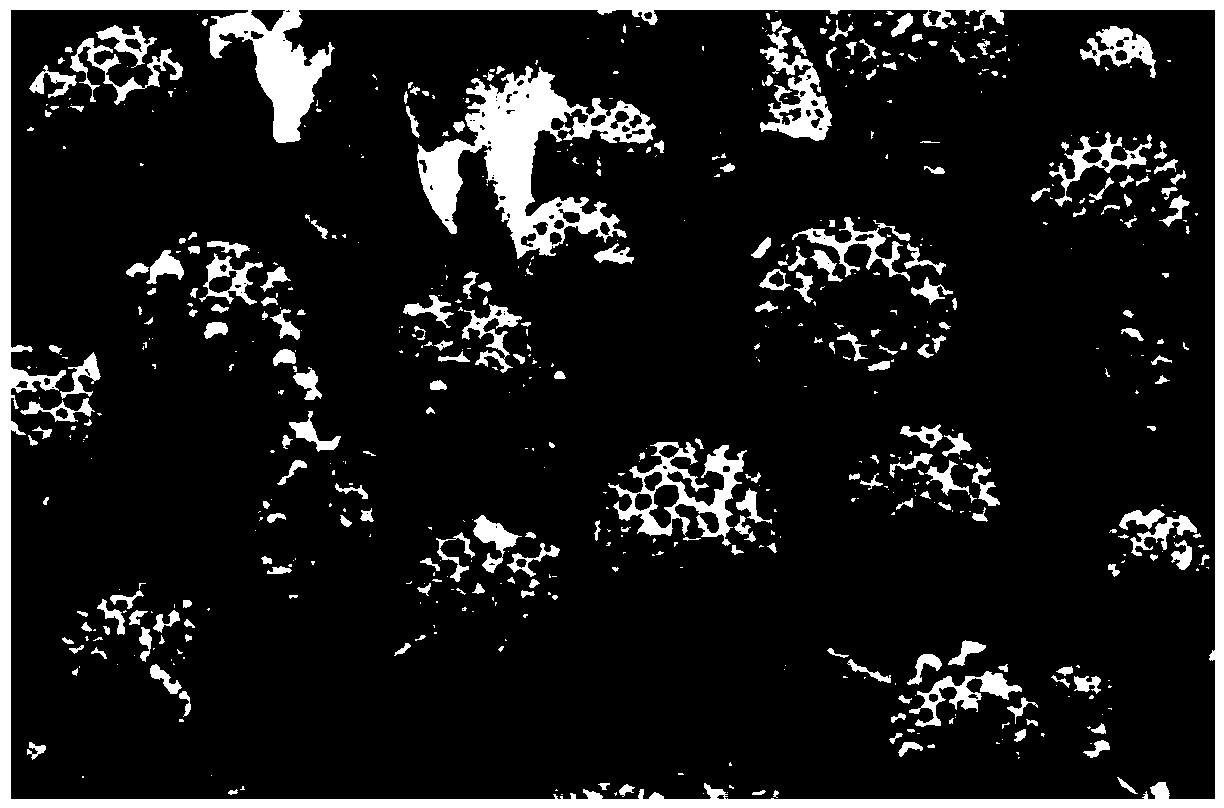

[0063] Investigate the effect of speed on the particle size of microspheres during mixing of double emulsion

[0064] Pretreatment of the raw material leuprolide acetate;

[0065] Put the 100 mg pretreated leuprolide acetate raw material into 300 mg of water and dissolve it as the inner aqueous phase W solution, and the inner aqueous phase W solution is not added with the allergenic auxiliary material gelatin;

[0066] Add 2.0 g of lactic acid-glycolic acid polymer to 20 g of dichloromethane as an oil phase O solution. The molecular weight of lactic acid-glycolic acid used is 12000-15000 and the molar ratio is 75:25;

[0067] The prepared inner water phase W solution and oil phase O solution are mixed, and the ultrasonic emulsification method is adopted. The ultrasonic power in the first stage is 10W, and the ultrasonic power in the second stage is 30W. Adjust the ultrasonic power to make the mixture become milky white, namely To obtain colostrum, the temperature of the colostrum solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com