Method for relieving pollution to ultrafiltration membrane under joint action of pre-oxidation and membrane modification

A combined action and ultrafiltration membrane technology, applied in chemical instruments and methods, oxidized water/sewage treatment, membrane technology, etc., can solve problems such as ultrafiltration membrane pollution, achieve less dosage, simple modification method, improved The effect of effluent water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

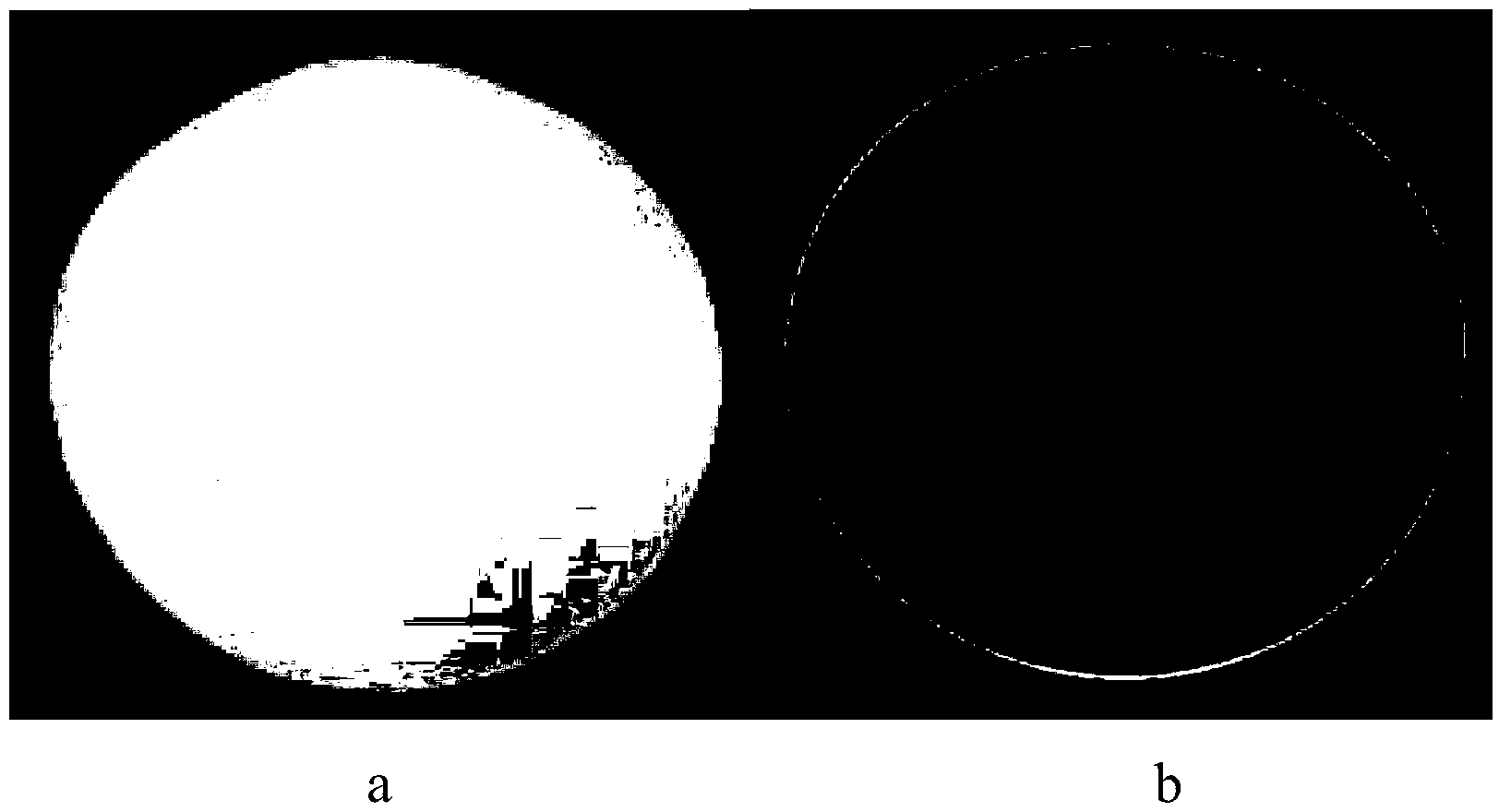

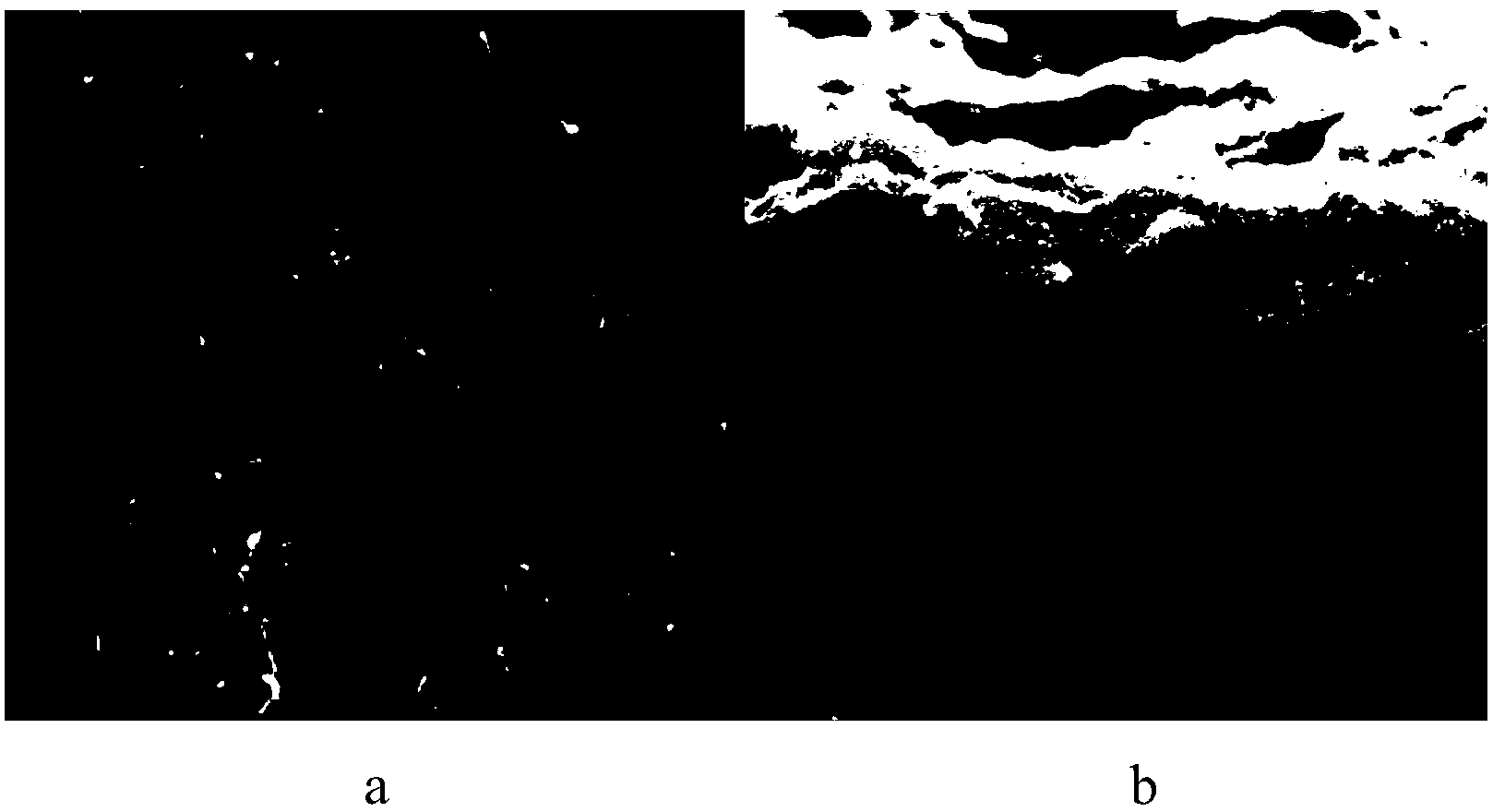

[0034] This example provides a method for reducing membrane fouling and improving effluent quality through combined action of ozone pre-oxidation and new carbon nanotube fiber material modified polysulfone membrane (20KDa). Specific steps are as follows:

[0035] The effluent from the secondary biological treatment of sewage is treated by microfiltration and then used for later use. The pore size of the microfiltration membrane is 0.45 microns;

[0036] The water sample filtered by the microfiltration membrane is subjected to ozone pre-oxidation treatment for later use, and the dosage of ozone is 2mgO 3 / mg DOC.

[0037] The polysulfone membrane (20kDa, the effective filtration area is 13.4cm 2 ) in an ethanol solution with a volume concentration of 30% for 2 hours to remove the membrane surface protective agent, then soak it in ultrapure water for 24 hours, and change the water once in the middle.

[0038] In a constant-pressure dead-end filtration device, the fully soaked...

Embodiment 2

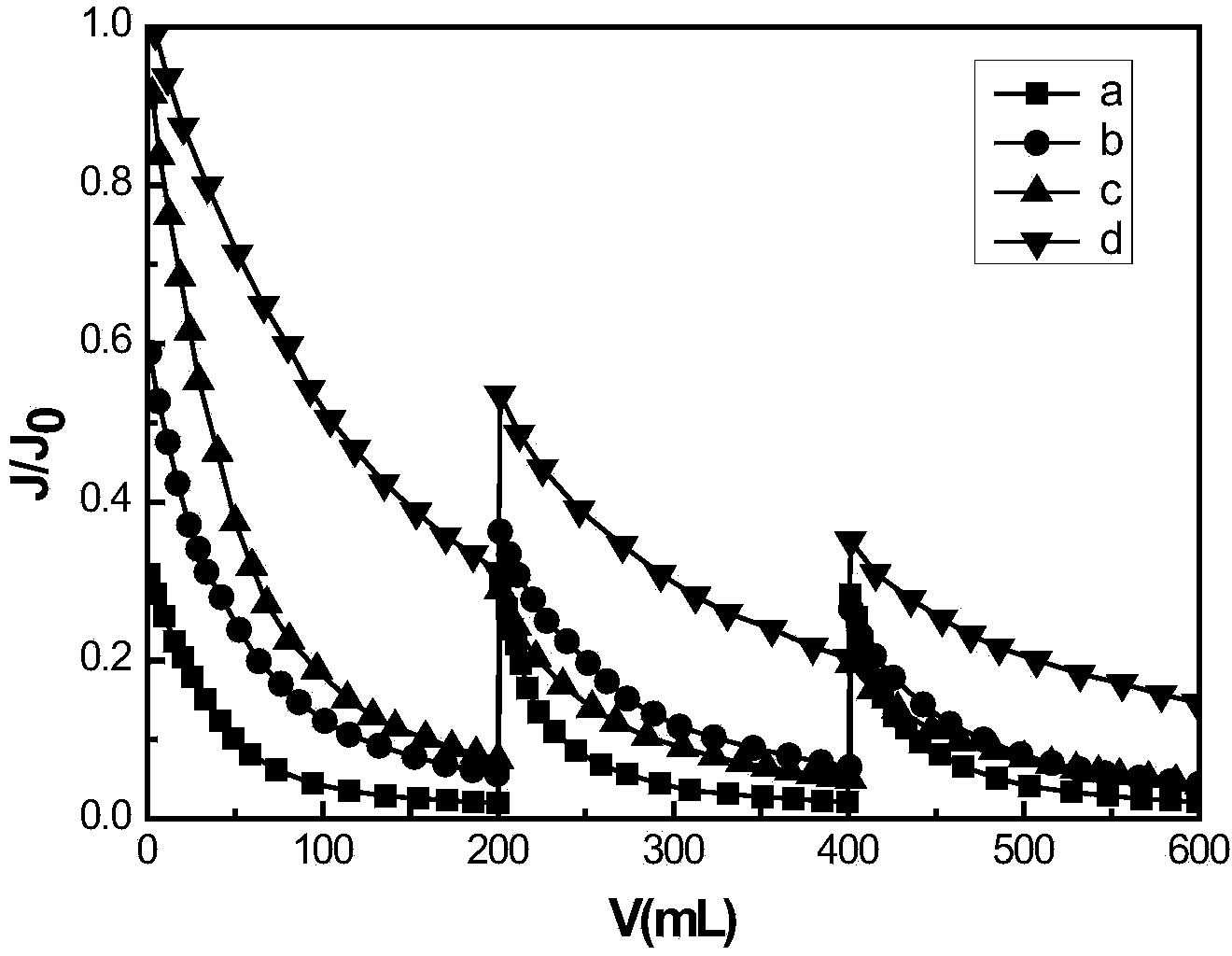

[0051] The polysulfone membrane in embodiment 1 is changed into polyethersulfone membrane (100KDa, effective filtration area is 13.4cm 2 ), other operations are with embodiment 1;

[0052] from Figure 5 and Image 6 It can be seen that the combination of the obtained ozone pre-oxidation and the new carbon nanotube fiber material modified polyethersulfone membrane has basically the same effects on membrane fouling and effluent quality improvement as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com