Devices for removing inorganic particles in sewage treatment system

A technology of sewage treatment system and inorganic particles, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Type filter press filter cloth wear and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

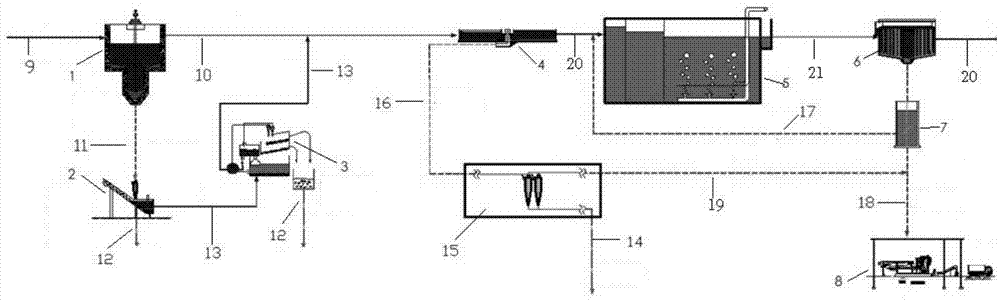

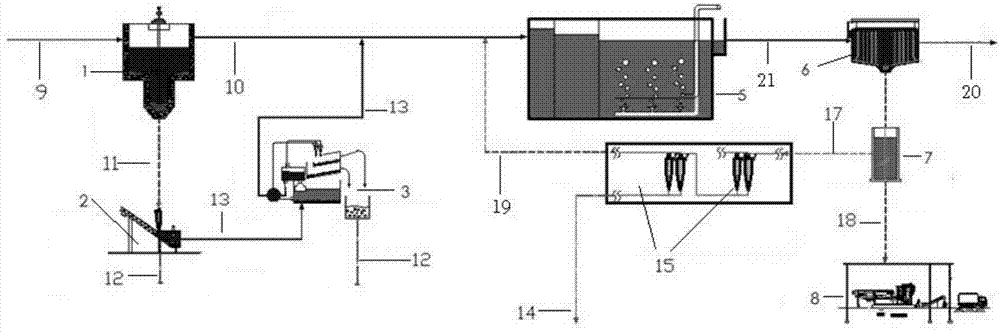

[0066] Embodiment 1 Assembly of the device of the present invention

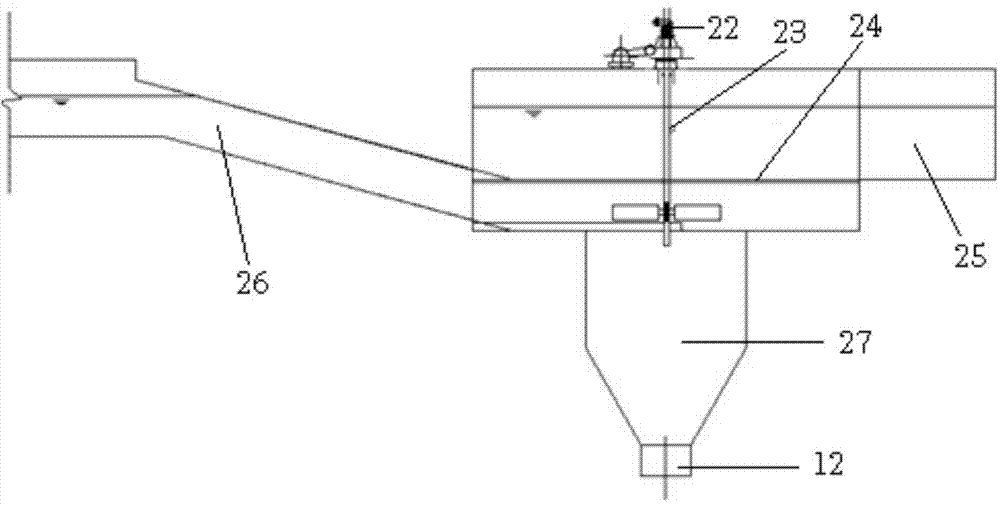

[0067] Such as figure 1 with figure 2 As shown, the grit chamber pretreatment system includes a high-efficiency grit chamber 1, a concentration integrated sand-water separator 2, and a fine sand screening and purifying machine 3.

[0068] The outlet water of the fine grid enters the high-efficiency grit chamber 1 through the water inlet pipe 9, the high-efficiency grit chamber removes inorganic particles in the sewage, and the sand-water mixture of the high-efficiency grit chamber enters the concentrated integrated sand-water separation through the sand-water mixture pipe 11 device 2, the high-efficiency grit chamber effluent flows through the high-efficiency grit chamber outlet pipe 10 to the biochemical pool 5. The high-efficiency grit chamber is based on the Bickers grit chamber. By simplifying the function of the grit chamber and optimizing the structure of the grit chamber, the ability to remove fin...

Embodiment 2

[0075] Embodiment 2 The use of device of the present invention

[0076] With a processing scale of 50,000 m 3 / d sewage plant as an example, its influent SS (suspended solids) and ISS (inorganic suspended solids) concentrations are 320mg / L and 200mg / L respectively, and the median diameter of SS is D50 = 105μm; two high-efficiency grit chambers are set , one set of concentrated integrated sand-water separator and one set of fine sand screening and purifying machine; the hydraulic retention time (HRT) of the biochemical tank is 12h, the concentration of organic matter in activated sludge (MLVSS) is controlled at 2100mg / L, and the sludge age (SRT) For 15 days, the sludge return ratio is 60%, and the MLSS of the return sludge in the secondary settling tank is 2.67 times that of the sludge in the biochemical tank.

[0077] The flow rate of the sand-water mixture produced by the grit chamber is 400m 3 / d, the dry weight of SS is 12.03t / d, and the dry weight of ISS is 7.52t / d. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Minimum particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com