A kind of preparation method of transparent nanocrystal doped glass

A technology of doping glass and nanocrystals, which is applied in the field of optical functional materials, can solve the problems of difficulty in preparing transparent nanocrystal-doped glass, poor controllability of nanocrystal size and content, and reduced glass permeability. High luminous intensity and quantum efficiency, good thermal stability, high luminous intensity and quantum efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

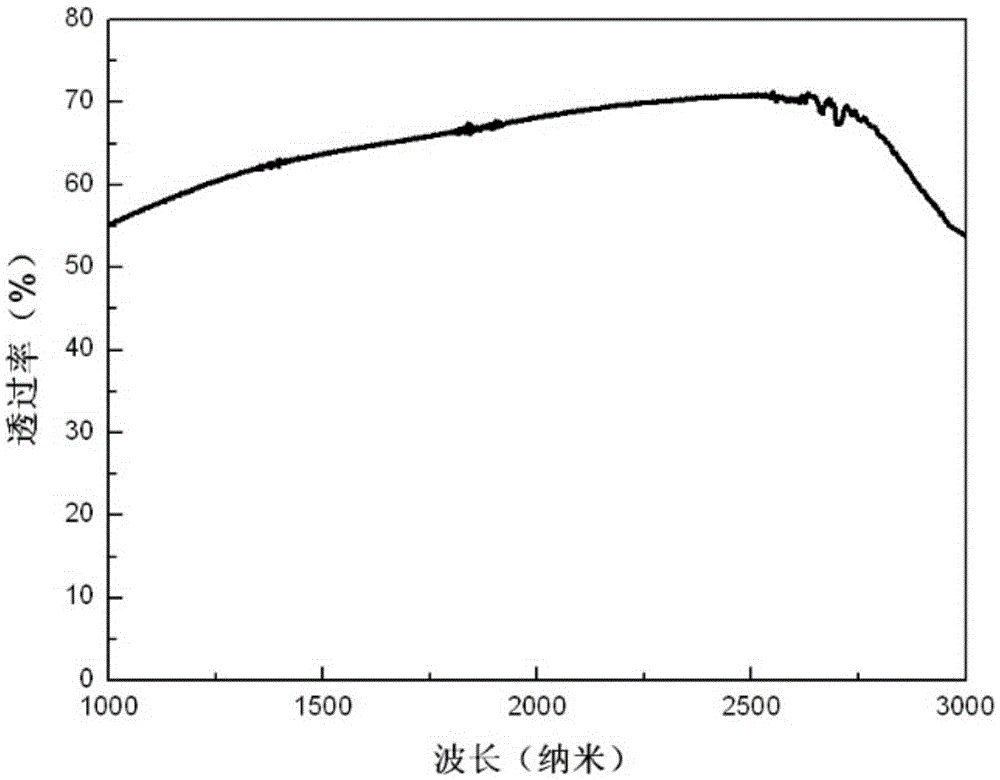

Embodiment 1

[0031] The composition of the nanocrystalline doped glass in this embodiment is: 90wt% tellurate glass and 10wt% YOF: Er 3+ Nanocrystalline. Among them, the molar composition of tellurite glass is: TeO 2 : 60%, ZnO: 25%, Na 2 O: 15%. Tellurite glass is prepared by traditional melting and quenching technology, and TeO is introduced according to the set molar ratio of the components. 2 , ZnO, Na 2 O and mixed evenly, melted at 760°C and held for 30 minutes, then passed through high-purity oxygen for 30 minutes to remove hydroxyl groups, and obtained large pieces of tellurite glass after quenching.

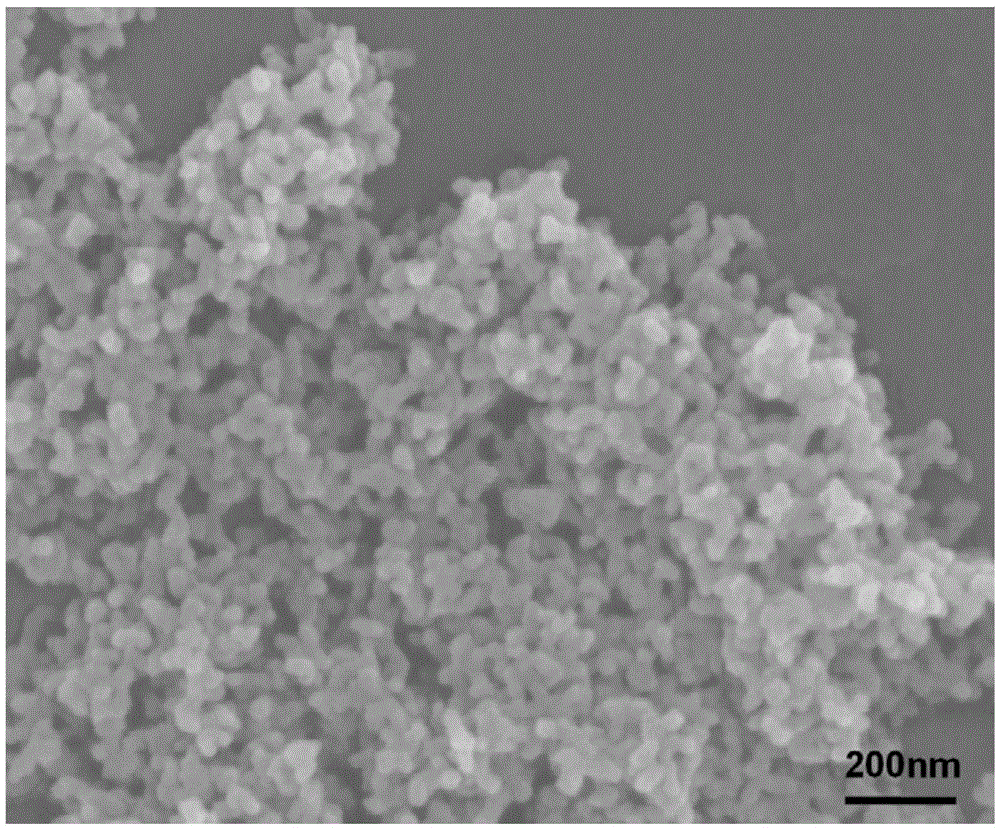

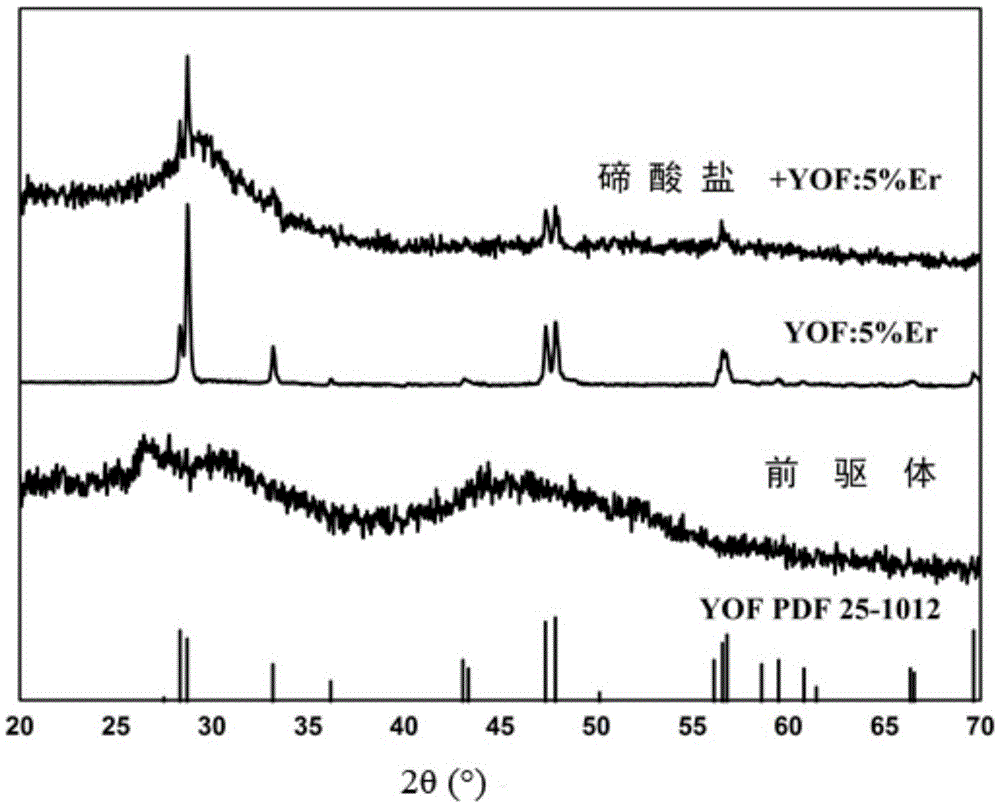

[0032] YOF of this example: 5% Er 3+ The nanocrystals are prepared by the following method: prepared by co-precipitation, mixing the corresponding cation solution according to the stoichiometric ratio, and performing magnetic stirring, adding KF and a certain amount of the same substance as the cation in the solution during the stirring process. A certain amount of CO (NH 2 ) ...

Embodiment 2

[0040] Except the following features, the preparation process of this embodiment is the same as that of Example 1:

[0041] The composition of the nanocrystalline doped glass in this embodiment is: 99.9wt% tellurate glass and 0.01wt% YOF: Er 3+ Nanocrystalline. The molar composition of the tellurite glass in this embodiment is: TeO 2 : 85%, ZnO: 5%, Na 2 O: 10%.

[0042] Step (4), in this embodiment, co-melting is carried out at 600° C., and nitrogen gas under negative pressure is introduced during the co-melting process to eliminate residual bubbles during the co-melting process.

[0043] The performance of the nanocrystal-doped glass prepared in this example is similar to that of Example 1, and will not be repeated here.

Embodiment 3

[0045] Except the following features, the preparation process of this embodiment is the same as that of Example 1:

[0046] The composition of the nanocrystalline doped glass in this embodiment is: 70wt% tellurate glass and 30wt% YOF: Er 3+ Nanocrystalline. The molar composition of the tellurite glass in this embodiment is: TeO 2 : 40%, ZnO: 20%, Na 2 O: 40%.

[0047] Step (4), in this embodiment, co-melting is carried out at 550° C., and positive-pressure nitrogen gas is introduced during the co-melting process to eliminate residual bubbles during the co-melting process.

[0048] The performance of the nanocrystal-doped glass prepared in this example is similar to that of Example 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com