Benzimidazole Binuclear Zinc Metal Complex and Its Application in PVC Heat Stabilizer

A technology of benzimidazole and heat stabilizer, applied in the direction of zinc organic compounds, etc., to achieve the effects of improving colorability and long-term thermal stability, good application prospects and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

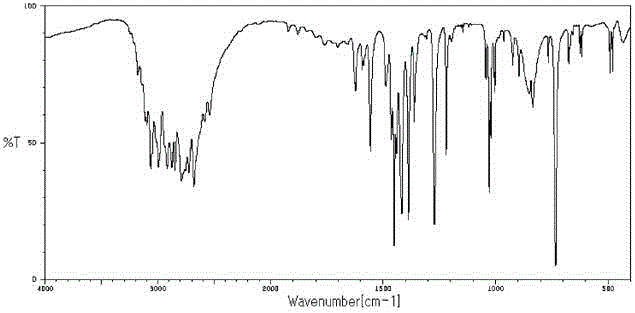

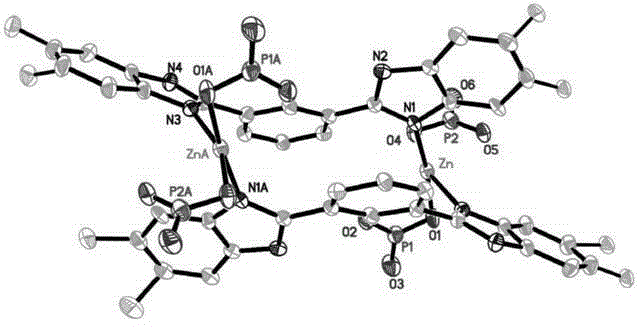

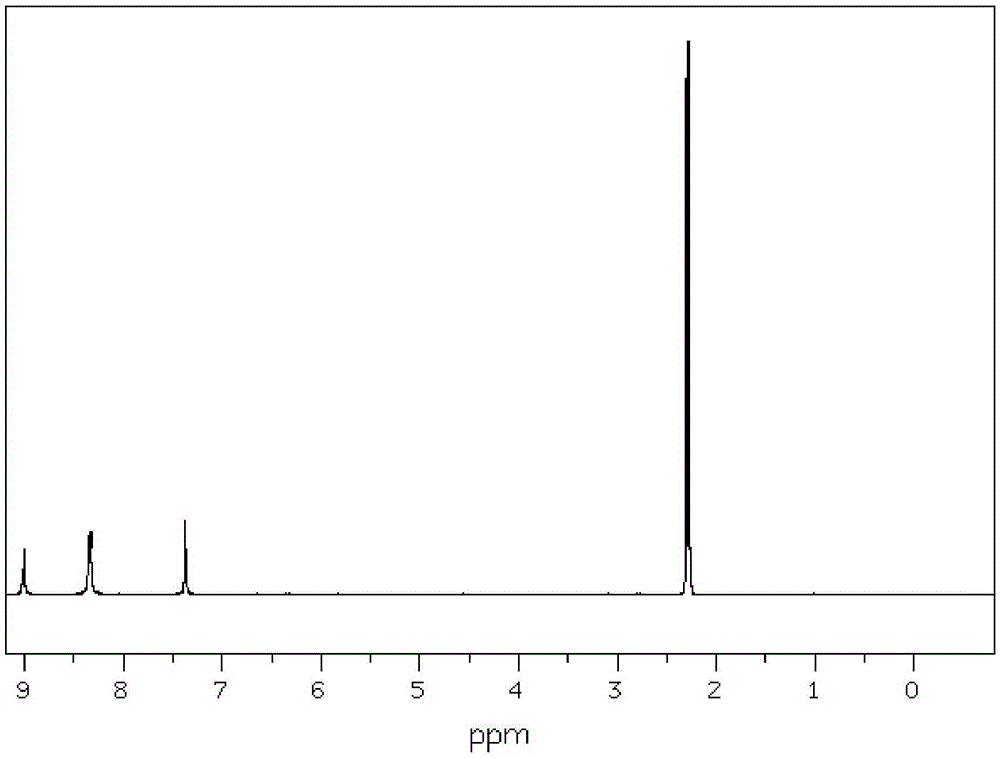

[0028] (1) Preparation of Ligand L

[0029] Weigh isophthalic acid (1.66g, 10mmol) and 4,5-dimethyl-o-phenylenediamine (3.40g, 25mmol), grind for half an hour, mix well, and add to a 100ml single-necked round bottom flask. 40ml of polyphosphoric acid was slowly added, and the mixture was slowly warmed up to 230°C in an oil bath, stirred and refluxed, and reacted for 4 hours. The temperature of the reaction solution was lowered to 100° C., and the obtained colorless solution was poured into 500 ml of ice water while vigorously stirring, and a large amount of white solids precipitated out. After suction filtration, the obtained solid was added to 600 ml of saturated aqueous sodium bicarbonate solution, and stirred for 12 hours. Filter again with suction and dry the resulting solid in an oven. Finally, recrystallize with 160ml of methanol and place it in the refrigerator to obtain a colorless crystal product, which is ligand L, 1,3-bis(2-(5,6-dimethylbenzimidazole))benzene, and...

Embodiment 2

[0040] Preparation of PVC heat stabilizer: the benzimidazole dinuclear zinc metal complex Zn prepared in Example 1 2 L 2 (H 2 PO 3 ) 4 It is used to prepare PVC heat stabilizer, and will be added to a certain amount of PVC to obtain PVC composition, and test the heat stability of PVC composition. The components of the PVC composition and the content (parts by weight) of each component are shown in Table 1.

[0041] The content of each component of the prepared PVC composition of table 1 embodiment 2

[0042] formula

W1

W2

W3

W4

W5

W6

pvc

100

100

100

100

100

100

20

20

20

20

20

20

Dioctyl phthalate

30

30

30

30

30

30

0.6

0.6

0.6

0.6

0.6

0.6

Paraffin

0.4

0.4

0.4

0.4

0.4

0.4

0.8

0.8

0.8

0.8

0.8

0.8

beta diket...

Embodiment 3

[0048] Different from Example 2, the PVC heat stabilizer consists of the following components in parts by weight: benzimidazole dinuclear zinc metal complex Zn 2 L 2 (H 2 PO 3 ) 4 3.5 parts, 10 parts of calcium carbonate, 40 parts of dioctyl phthalate, 0.4 parts of stearic acid, 0.5 parts of paraffin, 0.6 parts of calcium stearate and 0.6 parts of β-diketone. The PVC heat stabilizer will be added to 100 parts by weight of PVC to obtain a PVC composition. The thermal stability test of the PVC composition showed that it was still white after 80 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com