Clean fracturing fluid thickening agent and preparation method thereof

A technology for cleaning fracturing fluids and thickeners, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as inability to maintain clay stability, poor thermal stability of thickeners, cracks that cannot reach width and depth, etc. , to achieve the effect of good shear resistance, good dispersion of thickener and short liquid preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

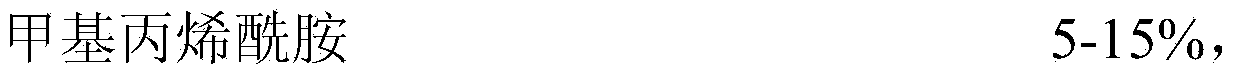

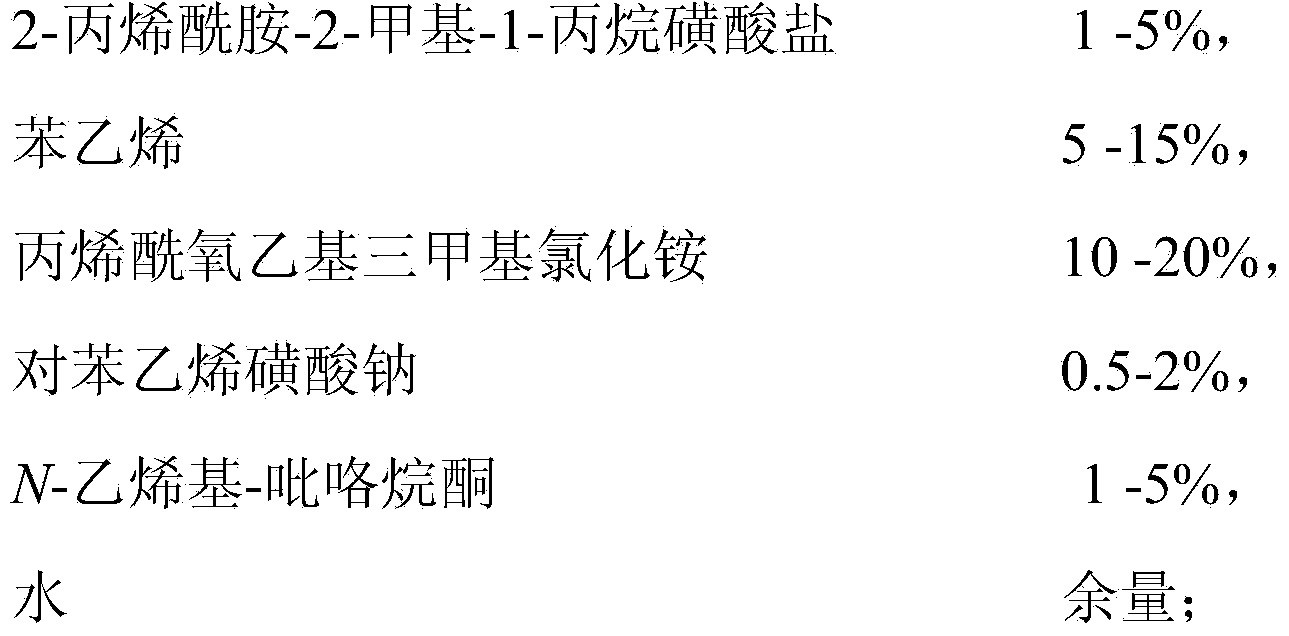

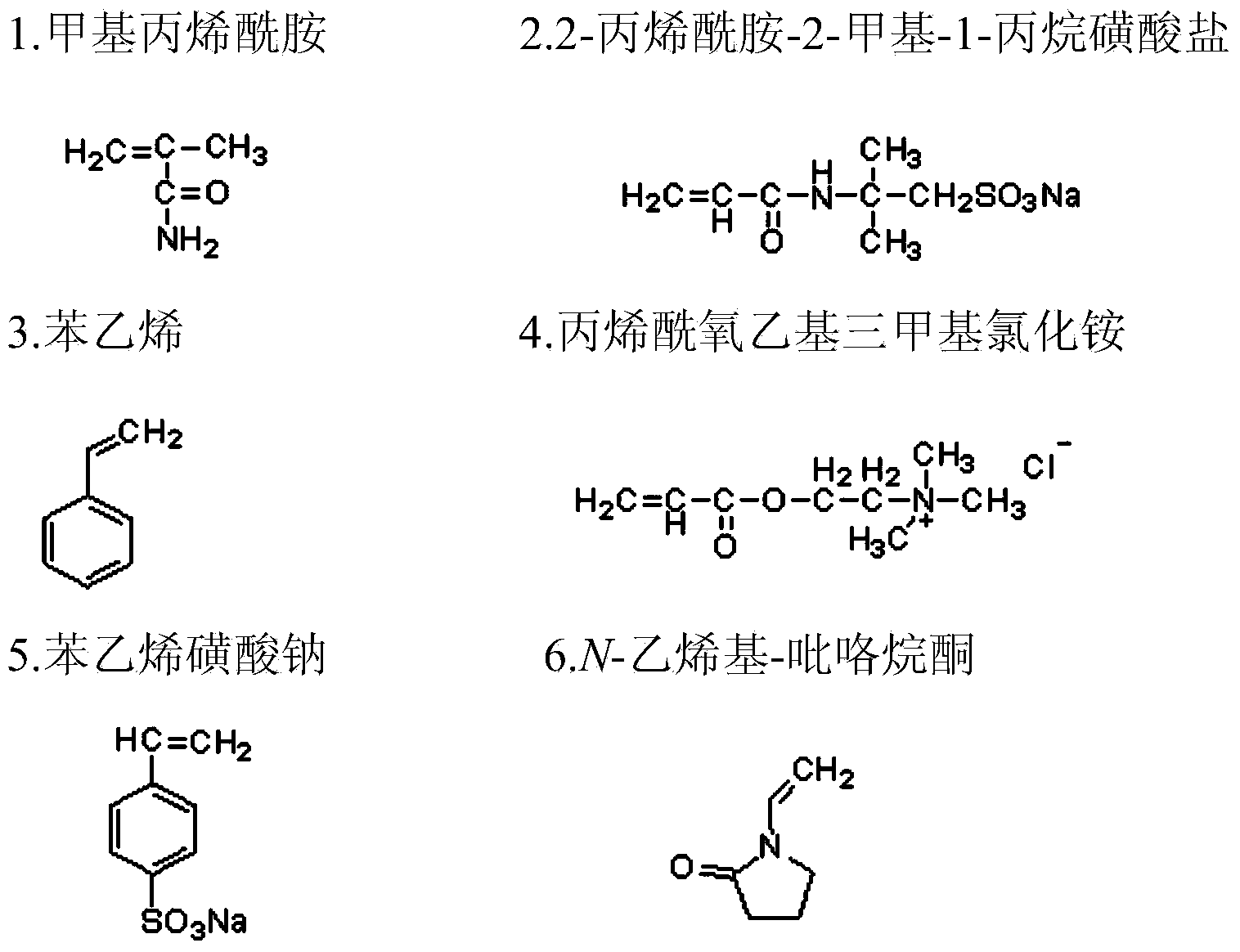

[0029] The weight percentage of each monomer and water in the reaction liquid is: AAM:AMPS:ST:DAC:BNS:NVP:water=10:3:10:15:1:5:56.

[0030] (1) Prepare mixed reaction solution: add 560g of distilled water to a 3000mL beaker, add 100g of monomer AAM, 30g of monomer AMPS, 100g of monomer ST, 150g of monomer DAC, 10g of monomer BNS, 50g of monomer NVP, and stir until completely dissolved ;

[0031] (2) Adjust the pH value of the mixed reaction solution to pH=8 with sodium hydroxide, and maintain the solution temperature at 15°C. Nitrogen deoxygenation by top blowing for 30 minutes, adding initiator (0.05 g of potassium persulfate, 0.06 g of sodium bisulfite, 0.06 g of azobisisobutyronitrile, and 0.05 g of sodium formaldehyde sulfoxylate are added to the mixed reaction solution) , causing 20 minutes to generate free radicals;

[0032] (3) Raise the temperature to room temperature, heat it with microwave method on medium heat (500W) for 2 minutes to mix it evenly, then take it ou...

Embodiment 2

[0036] The weight percentage of each monomer and water in the reaction liquid is: AAM:AMPS:ST:DAC:BNS:NVP:water=15:1:15:10:2:3:54.

[0037] (1) Prepare mixed reaction solution: add 540g of distilled water to a 3000mL beaker, add 150g of monomer AAM, 10g of monomer AMPS, 150g of monomer ST, 100g of monomer DAC, 20g of monomer BNS, 30g of monomer NVP, and stir until completely dissolved ;

[0038] (2) Adjust the pH value of the mixed reaction solution to pH=9 with sodium hydroxide, and maintain the solution temperature at 15°C. Nitrogen deoxygenation by top blowing for 30 minutes, adding initiator (adding ammonium sulfate 0.03g, azobisisobutylamidine hydrochloride 0.08g, azobisisobutyronitrile 0.03g, formaldehyde sulfoxylate in every liter of mixed reaction liquid Sodium hydrogen 0.08g), trigger 20 minutes to produce free radicals;

[0039] (3) Raise the temperature to room temperature, heat it with medium heat (500W) by the microwave method for 3 minutes, mix it evenly, then ...

Embodiment 3

[0043] The weight percentage of each monomer and water in the reaction liquid is: AAM:AMPS:ST:DAC:BNS:NVP:water=5:5:10:20:1:4:55.

[0044] (1) Prepare mixed reaction solution: add 550g of distilled water into a 3000mL beaker, add 50g of monomer AAM, 50g of monomer AMPS, 100g of monomer ST, 200g of monomer DAC, 10g of monomer BNS, and 40g of monomer NVP, and stir until completely dissolved;

[0045] (2) Adjust the pH value of the mixed reaction solution to pH=8 with sodium hydroxide, and maintain the solution temperature at 15°C. Nitrogen deoxygenation by top blowing for 30 minutes, adding initiator (adding ammonium sulfate 0.07g, azobisisobutylamidine hydrochloride 0.04g, azobisisobutyronitrile 0.07g, formaldehyde sulfoxylate in every liter of mixed reaction liquid Sodium hydrogen 0.04g), trigger 18 minutes to produce free radicals;

[0046] (3) Raise the temperature to room temperature, heat it with microwave method on medium heat (500W) for 2 minutes to mix it evenly, then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com