A high-concentration intermittent discharge organic waste gas treatment process

A technology of organic waste gas and treatment process, which is applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., and can solve problems such as the inapplicability of high-concentration organic gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

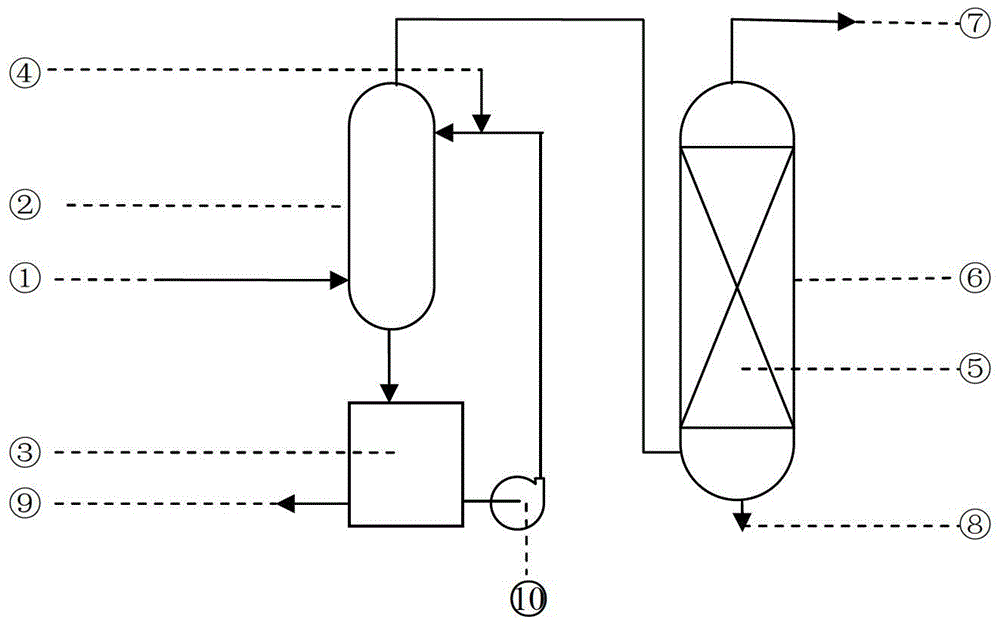

Method used

Image

Examples

Embodiment 1

[0033] The composition of exhaust gas is H 2 S 2000mg / m 3 , NH 3 2000mg / m 3 , methyl mercaptan 100mg / m 3 , dimethyl sulfide 50mg / m 3 , ethanethiol 60mg / m 3 , volatile organic compounds 6000mg / m 3 ;Exhaust gas flow rate 0~100m 3 / h, average 60m 3 / h; normal temperature and pressure.

[0034] The composition of the absorption liquid is 0.1%wH 2 SO 4 , the oxidant is 5%w sodium hypochlorite, and its flow rate is 0.036m 3 / h.

[0035] Adsorbent is large particle coal-based activated carbon 1m 3 .

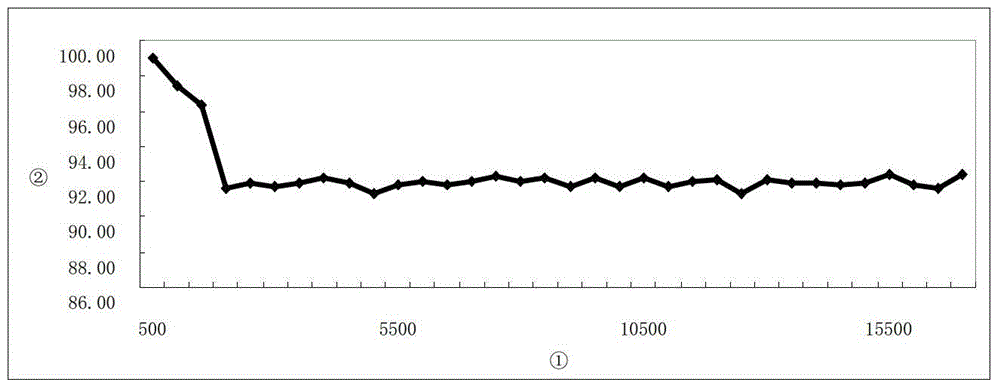

[0036] Processing effect:

[0037] Purified gas composition: H 2 S 0.8mg / m 3 , NH 3 2.0mg / m 3 , methyl mercaptan 0.5mg / m 3 , dimethyl sulfide 0.3mg / m 3 , ethanethiol 0.8mg / m 3 , volatile organic compounds 500mg / m 3 . Exhaust gas treatment capacity 1752km 3 / m 3 , see the attached picture for the actual effect figure 2 .

Embodiment 2

[0046] The composition of exhaust gas is H 2 S 1200mg / m 3 , NH 3 2000mg / m 3 , methyl mercaptan 60mg / m 3 , dimethyl sulfide 50mg / m 3 , ethanethiol 60mg / m 3 , volatile organic compounds 3600mg / m 3 ;Exhaust gas flow rate 0~100m 3 / h, average 60m 3 / h; normal temperature and pressure.

[0047] The composition of the absorption liquid is 0.1%wH 2 SO 4 , the oxidant is 5%w sodium chlorate, and its flow rate is 0.045m 3 / h.

[0048] Adsorbent is large particle coal-based activated carbon 1m 3 .

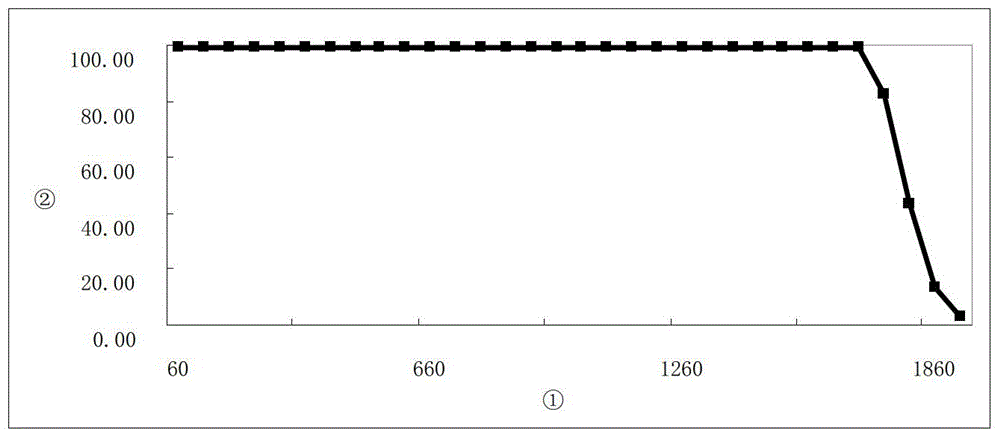

[0049] Processing effect:

[0050] Purified gas composition: H 2 S 0.5mg / m 3 , NH 3 2.0mg / m 3 , methyl mercaptan 0.4mg / m 3 Dimethyl sulfide 0.3mg / m 3 Ethanthiol 0.7mg / m 3 , volatile organic compounds 460mg / m 3 . Exhaust gas treatment capacity 3353km 3 / m 3 , see the attached picture for the actual effect Figure 4 .

Embodiment 3

[0059] The composition of exhaust gas is H 2 S 3000mg / m 3 , NH 3 2000mg / m 3 , methyl mercaptan 200mg / m 3 , dimethyl sulfide 100mg / m 3 , ethanethiol 80mg / m 3 , volatile organic compounds 6000mg / m 3 ;Exhaust gas flow rate 0~100m 3 / h, average 60m 3 / h; normal temperature and pressure.

[0060] The composition of the absorption liquid is 0.1%wH 2 SO 4 , the oxidant is 5%w sodium hypochlorite, and its flow rate is 0.04m 3 / h.

[0061] Adsorbent is large particle coal-based activated carbon 1m 3 .

[0062] Processing effect:

[0063] Purified gas composition: H 2 S 0.8mg / m 3 , NH 3 2.0mg / m 3 , methyl mercaptan 0.6mg / m 3 , dimethyl sulfide 0.3mg / m 3 , ethanethiol 0.8mg / m 3 , volatile organic compounds 500mg / m 3 . Exhaust gas treatment capacity 1528km 3 / m 3 , see the attached picture for the actual effect Figure 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com