A Method of Using Dielectric/Ferromagnetic Composite Materials to Absorb Microwaves

A composite material and dielectric technology, applied in radiation-absorbing coatings, chemical instruments and methods, and other chemical processes, can solve problems such as narrow absorption frequency bands, and achieve the effects of wide frequency bands, broad application prospects, and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The described dielectric / ferromagnetic composite microwave absorbing material is prepared in the following steps:

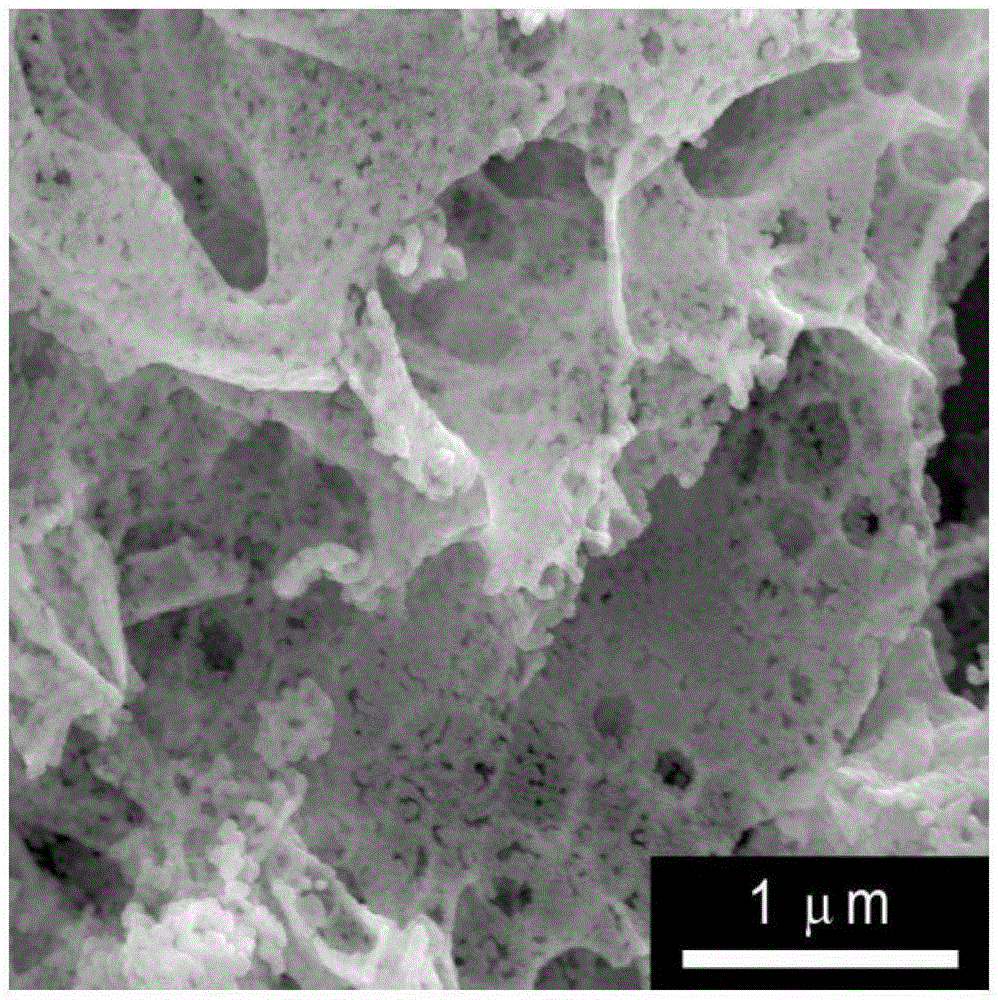

[0024] (1) Using the sol-gel method, using ethylene glycol methyl ether and monoethanolamine as solvents, lanthanum nitrate and nickel acetate as starting materials, annealing at 700 °C for 1.5 hours in air to obtain loose and porous nickel acid with oxygen vacancies Lanthanum powder (such as figure 1 shown);

[0025] (2) Carbon-coated iron-cobalt nanocapsules were prepared by DC plasma arc method;

[0026] (3) 50wt% lanthanum nickelate (LaNiO 3 ) powder and 50wt% iron-cobalt-cobalt-carbon (FeCo / C) nanocapsules were dispersed in ethanol, and then the two suspensions were ultrasonically mixed, mixed uniformly and then dried to obtain LaNiO 3 -FeCo / C (50 / 50) composite.

[0027] (4) Preparation of absorbing samples:

[0028] 0.4g LaNiO prepared in step (3) 3 -FeCo / C(50 / 50) composite mixed with 0.6g paraffin (LaNiO 3 -FeCo / C (50 / 50) composite material h...

Embodiment 2

[0030] The described dielectric / ferromagnetic composite microwave absorbing material is prepared in the following steps:

[0031] (1) Using the sol-gel method, using ethylene glycol methyl ether and monoethanolamine as solvents, lanthanum nitrate and nickel acetate as starting materials, annealing at 700 °C for 1.5 hours in air to obtain loose and porous nickel acid with oxygen vacancies Lanthanum powder (such as figure 1 shown);

[0032] (2) Carbon-coated iron-cobalt nanocapsules were prepared by DC plasma arc method;

[0033] (3) 80wt% lanthanum nickelate (LaNiO 3 ) powder and 20wt% iron-cobalt-cobalt-carbon (FeCo / C) nanocapsules were dispersed in ethanol, then the two suspensions were ultrasonically mixed, mixed uniformly and then dried to obtain LaNiO 3 -FeCo / C (80 / 20) composite.

[0034] (4) Preparation of absorbing samples:

[0035] 0.4g LaNiO prepared in step (3) 3 -FeCo / C(80 / 20) composite mixed with 0.6g paraffin (LaNiO 3 -FeCo / C (80 / 20) composite material has a...

Embodiment 3

[0037] The difference from Example 2 is: lanthanum nickelate (LaNiO 3 ) powder and carbon-coated iron cobalt (FeCo / C) nanocapsules with a mass ratio of 20:80, and the obtained composite material is LaNiO 3 -FeCo / C(20 / 80), the reflection loss of the absorbing sample made of this composite material has absorption below -10dB at different frequencies (see Image 6 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com