Tubular cobalt-hybridized g-C3N4 material, microwave synthesis method thereof and application of tubular cobalt-hybridized g-C3N4 material in field of supercapacitors

A microwave synthesis, g-c3n4 technology, applied in hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, nitrogen and non-metallic compounds, etc., can solve the problems of limited application, microwave insensitivity, etc. Simple, good crystallization results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

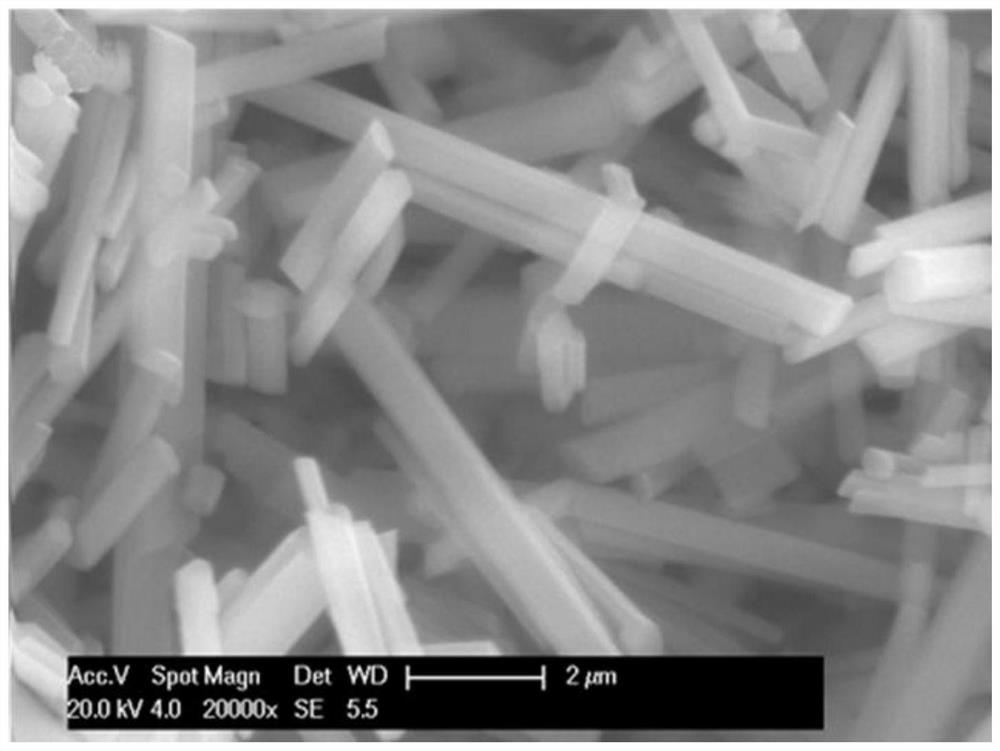

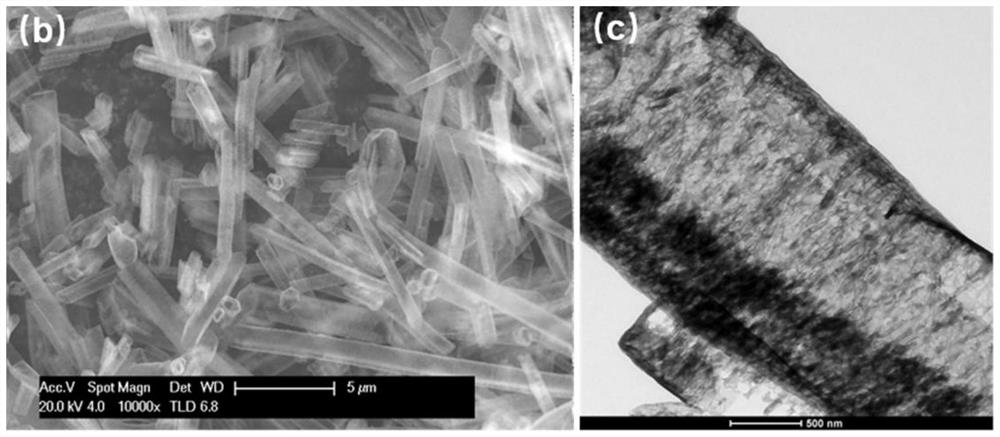

[0038] Such as figure 1 As shown, a tubular cobalt hybrid g-C 3 N 4 The microwave synthesis method of material comprises the following steps:

[0039] S1. Dissolve 8g of melamine and 8g of cyanuric acid powder in 400ml of deionized water, respectively, and heat them in a water bath to 80°C to form a saturated solution. Mix the above-mentioned saturated melamine clear solution with the saturated cyanuric acid clear solution to form a loose structure The melamine-cyanuric acid supramolecular aggregate;

[0040] S2. After the melamine-cyanuric acid supramolecular aggregates are centrifugally cleaned, they are redispersed in 400ml aqueous solution to form a 450ml mixed solution, and the mixed solution is divided into 6 parts of 75ml mixed solution, and these 6 parts of 75ml mixed solution The solution was transferred to six 100ml polytetrafluoroethylene reaction kettles, and was subjected to hydrothermal reaction in an oven at 150°C for 12 hours for recrystallization treatment;...

Embodiment 2

[0048] Such as figure 1 As shown, a tubular cobalt hybrid g-C 3 N 4 The microwave synthesis method of material comprises the following steps:

[0049] S1. Dissolve 8g of melamine and 8g of cyanuric acid powder in 400ml of deionized water, respectively, and heat them in a water bath to 80°C to form a saturated solution. Mix the above-mentioned saturated melamine clear solution with the saturated cyanuric acid clear solution to form a loose structure The melamine-cyanuric acid supramolecular aggregate;

[0050] S2. After the melamine-cyanuric acid supramolecular aggregates are centrifugally cleaned, they are redispersed in 400ml aqueous solution to form a 450ml mixed solution, and the mixed solution is divided into 6 parts of 75ml mixed solution, and these 6 parts of 75ml mixed solution The solution was transferred to six 100ml polytetrafluoroethylene reaction kettles, and recrystallized in a 150°C oven for 9 hours; after the reaction was completed, it was centrifuged and fre...

Embodiment 3

[0055] Such as figure 1 As shown, a tubular cobalt hybrid g-C 3 N 4 The microwave synthesis method of material comprises the following steps:

[0056] S1. Dissolve 8g of melamine and 8g of cyanuric acid powder in 400ml of deionized water, respectively, and heat them in a water bath to 80°C to form a saturated solution. Mix the above-mentioned saturated melamine clear solution with the saturated cyanuric acid clear solution to form a loose structure The melamine-cyanuric acid supramolecular aggregate;

[0057] S2. After the melamine-cyanuric acid supramolecular aggregates are centrifugally cleaned, they are redispersed in 400ml aqueous solution to form a 450ml mixed solution, and the mixed solution is divided into 6 parts of 75ml mixed solution, and these 6 parts of 75ml mixed solution The solution was transferred to six 100ml polytetrafluoroethylene reaction kettles, and recrystallized in a 120°C oven for 12 hours. After the reaction was completed, it was centrifuged and fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com