Iron removal refining agent for preparation of free-cutting brass through melting of scrap brass

The technology of refining agent and miscellaneous brass is applied in the field of iron-removing refining agent for preparing free-cutting brass by smelting waste miscellaneous brass. Add and use convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

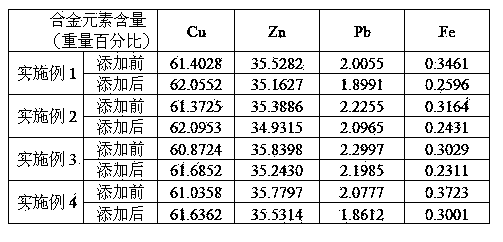

Examples

Embodiment 1

[0024] An iron-removing smelting agent for preparing free-cutting brass by smelting waste miscellaneous brass, the iron-removing smelting agent is made by mixing the following components by mass percentage: CuZr master alloy powder (Zr content is 70% by mass) 20%, CuTi master alloy powder (20% by mass of Ti) 15%, CuP master alloy powder (10% by mass of P) 25%, sodium carbonate 5%, potassium sulfate 35%.

[0025] According to the above ratio, the CuZr master alloy powder (fineness 20 mesh to 100 mesh), CuTi master alloy powder (fineness 20 mesh to 100 mesh), CuP master alloy powder (fineness 20 mesh to 100 mesh), sodium carbonate And potassium sulphate are mixed uniformly, put into an electric furnace and heated to 200°C for 3 hours, and finally coated with copper foil to form a block.

Embodiment 2

[0027] An iron-removing refining agent for preparing free-cutting brass by smelting waste miscellaneous brass, said iron-removing refining agent is made by mixing the following components by mass percentage: CuZr master alloy powder (Zr content is 20% by mass) 40%, CuTi master alloy powder (70% by mass of Ti) 5%, CuP master alloy powder (20% by mass of P) 15%, sodium carbonate 15%, potassium sulfate 25%.

[0028] According to the above ratio, the CuZr master alloy powder (fineness 20 mesh to 100 mesh), CuTi master alloy powder (fineness 20 mesh to 100 mesh), CuP master alloy powder (fineness 20 mesh to 100 mesh), sodium carbonate Mix it with potassium sulfate and heat it to 350°C for 2 hours in an electric furnace, and finally wrap it with a copper tube to form a block.

Embodiment 3

[0030] An iron removing refining agent for preparing free-cutting brass by smelting waste miscellaneous brass. The iron removing refining agent is made by mixing the following components by mass percentage: CuZr master alloy powder (the content of Zr is 30% by mass) 40%, CuTi master alloy powder (50% by mass of Ti) 10%, CuP master alloy powder (15% by mass of P) 20%, sodium carbonate 10%, potassium sulfate 20%.

[0031] According to the above ratio, the CuZr master alloy powder (fineness 20 mesh to 100 mesh), CuTi master alloy powder (fineness 20 mesh to 100 mesh), CuP master alloy powder (fineness 20 mesh to 100 mesh), sodium carbonate Mix it with potassium sulfate and heat it to 300°C for 2.5 hours in an electric furnace, and finally wrap it with copper foil or copper tube to form a block.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com