Method for reducing protein content in soybean dietary fiber

A technology for soybean dietary fiber and protein content, applied in food preparation, food science, application and other directions, can solve problems such as reducing protein content, and achieve the effects of simple preparation process, extended shelf life, and not easy to absorb moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Embodiment 1 A kind of method that reduces protein content in soybean dietary fiber

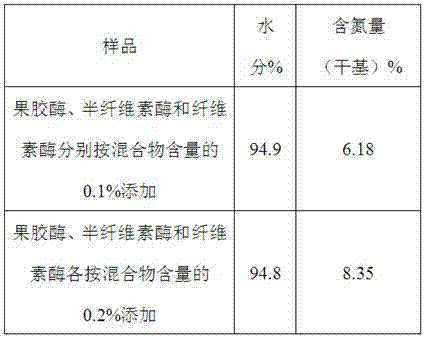

[0012] Add water to the dried bean dregs, the mass ratio of dried bean dregs to water is 1:20, adjust the pH to 6.65, then add 0.1% neutral protease (provided by Novozymes) on a dry basis, keep shaking at 60°C for 2 hours, shake The final composition was centrifuged at a speed of 3000r / min, and the centrifugation time was 10min. The supernatant was removed to obtain the lower sediment, and the sediment was washed with water 20 times the mass of dried bean dregs, and then added in an amount of 1:20 by mass volume ratio. Water, adjust the pH to be 6.65, then, add the mixture enzyme of pectinase, hemicellulase and cellulase, the addition of pectinase, hemicellulase and cellulase is 0.1% of the mixture after adding water to the sediment, and the fruit The mass percentage of gelatinase, hemicellulase and cellulase is 1:1:1, incubated and shaken at 60°C for 2 hours, then the fiber is separat...

Embodiment 2

[0013] Example 2 A method for reducing protein content in soybean dietary fiber

[0014] Add water to the dried bean dregs, the mass ratio of dried bean dregs to water is 1:15, adjust the pH to 7.0, then add 0.15% neutral protease (provided by Novozymes) on a dry basis, keep shaking at 60°C for 3 hours, shake The final composition was centrifuged at a speed of 3000r / min, and the centrifugation time was 10min. The supernatant was removed to obtain the lower sediment, and the sediment was washed with water 20 times the mass of dried bean dregs, and then added in an amount of 1:15 by mass volume ratio. Water, adjust the pH to be 7.0, then, add the mixture enzyme of pectinase, hemicellulase and cellulase, the addition of pectinase, hemicellulase and cellulase is 0.15% of the mixture after adding water to the sediment, and the fruit The mass percentage of gelatinase, hemicellulase and cellulase is 1:2:1, incubated and shaken at 60°C for 4 hours, and then the fiber is separated from...

Embodiment 3

[0015] Embodiment 3 A method for reducing protein content in soybean dietary fiber

[0016] Add water to the dried bean dregs, the mass ratio of dried bean dregs to water is 1:25, adjust the pH to 6.5, then add 0.15% neutral protease (provided by Novozymes) on a dry basis, keep shaking at 60°C for 4 hours, shake The final composition was centrifuged at a speed of 3000r / min, and the centrifugation time was 10min. The supernatant was removed to obtain the lower sediment, and the sediment was washed with water 20 times the mass of dried bean dregs, and then added in an amount of 1:25 by mass volume ratio. Water, adjust the pH to be 6.5, then, add the mixture enzyme of pectinase, hemicellulase and cellulase, the addition of pectinase, hemicellulase and cellulase is 0.2% of the mixture after adding water to the sediment, and the fruit The mass percentage of gelatinase, hemicellulase and cellulase is 2:2:1, incubated and shaken at 60°C for 3 hours, and then the fiber is separated fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com